High performance ORR (oxygen reduction reaction) PGM (pt group metal) free catalyst

A catalyst, transition metal technology, applied in the field of platinum group metal-free catalysts, which can solve the problems of insufficient commercial application, low porosity, and lack of stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

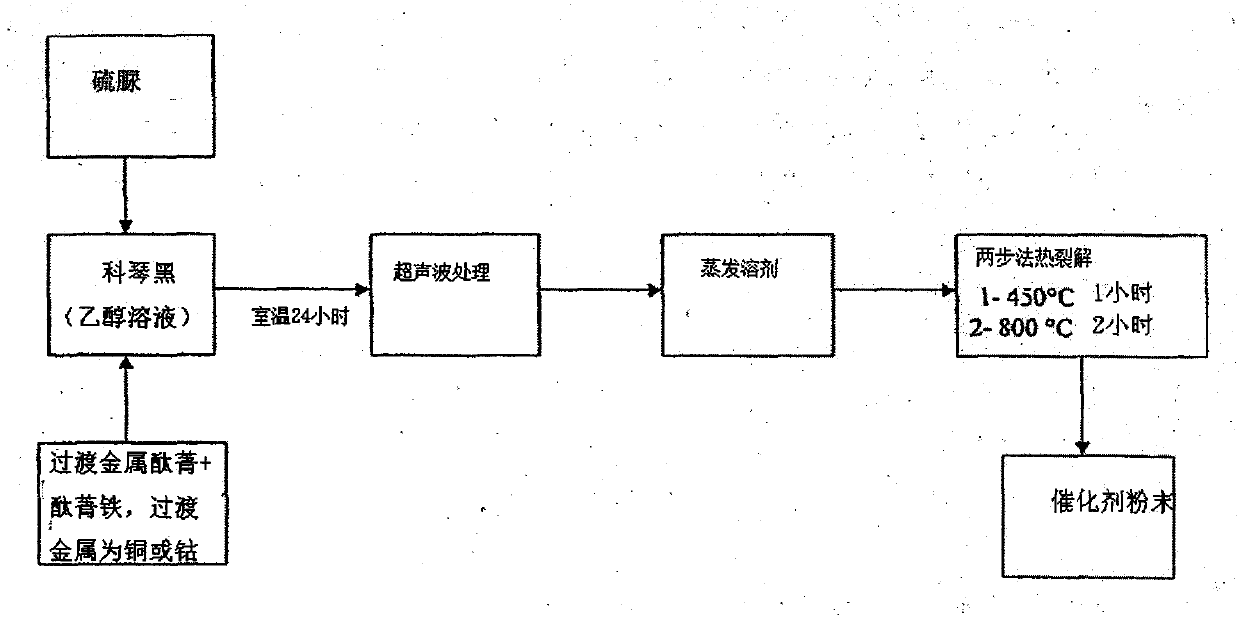

[0051] Catalysts of the present invention are prepared by thermally treating the blend comprising:

[0052] a) phthalocyanine (PC) iron of general formula (I)

[0053]

[0054] in

[0055] M is Fe 2+ , Fe 3+

[0056] R is hydrogen or an electron withdrawing substituent

[0057] Wherein when M=Fe 3+ When there is a compensation ion X -

[0058] b) a transition metal phthalocyanine (Metal-PC) of general formula (II)

[0059]

[0060] in

[0061] M' is Cu 2+ or Co 2+

[0062] R', other than R, is hydrogen or an electron-withdrawing substituent

[0063] c) a nitrogen and sulfur compound

[0064] d) A conductive porous carbon material

[0065] The temperature and time of the heat treatment according to the invention are sufficient to first polymerize and then at least partially thermally crack the phthalocyanine, so the heat treatment is for example at 350-900° C. for at least 0.5 hours. The heat treatment is the basic step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com