Carbon nitride-based homo-junction for photocatalytic production of hydrogen peroxide, and preparation method and application thereof

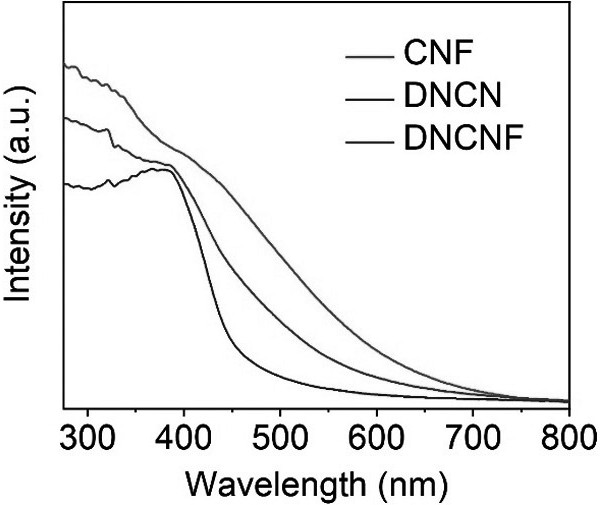

A technology based on carbon nitride and hydrogen oxidation, applied in the field of material chemistry, can solve the problems of weak light absorption ability and easy recombination of photogenerated carriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

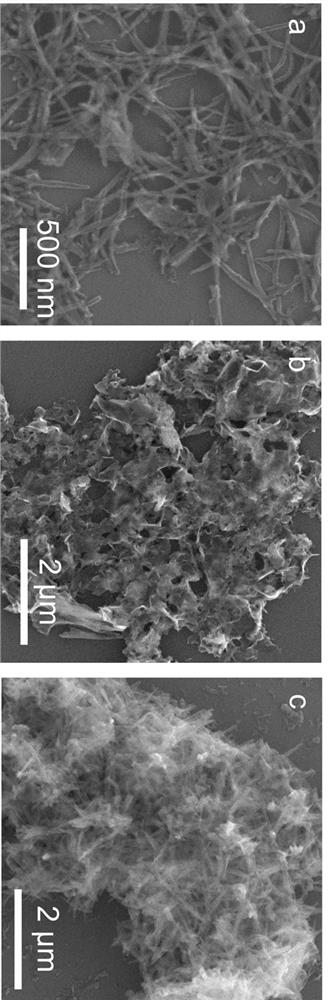

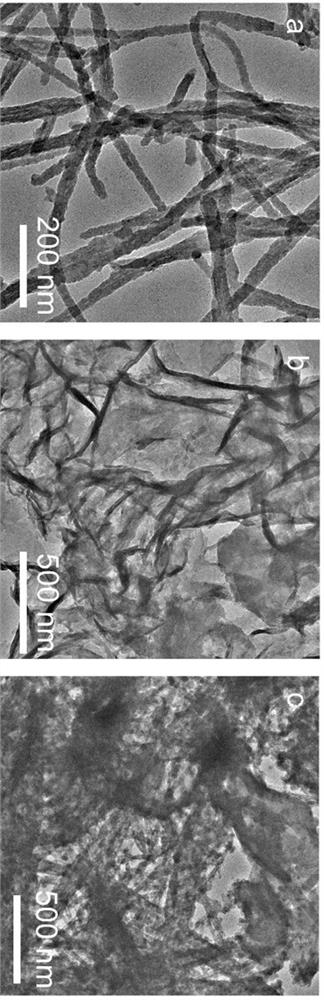

[0025] (1) Preparation of carbon nitride nanosheet DNCN

[0026] Put 2 g of dicyandiamide and 10 g of ammonium chloride into a mortar and mix for 1 h, then put it into a muffle furnace to raise the temperature to 550 °C at a heating rate of 1 °C / min, keep it at this temperature for 3 h, and calcinate After the end, the obtained DNCN powder was ground until no obvious particles existed, and put into a storage vial for later use.

[0027] (2) Acidification of flaky carbon nitride

[0028] Take 1 g of the flake-shaped carbon nitride obtained in the above step (1) and put it into 60 mL, 3mol / L hydrochloric acid for 30 minutes and ultrasonic power 100 W to make it evenly dispersed, then stir for 12 h at a stirring rate of about 800 rpm . After the stirring is completed, centrifuge and wash with deionized water until the pH of the supernatant is close to neutral, and finally put it into a 60°C oven to dry to obtain acidified carbon nitride nanosheets.

[0029] (3) Synthesis of fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com