Filter membrane preparation method and filter membrane

A filter membrane and nanofiltration membrane technology, applied in the field of chemical materials, can solve the problems of inability to effectively absorb photons in the visible light region, limit practical applications, and high economic costs, achieve effective separation efficiency of photogenerated charge carriers, and facilitate recycling and reuse , avoid the effect of rapid compounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

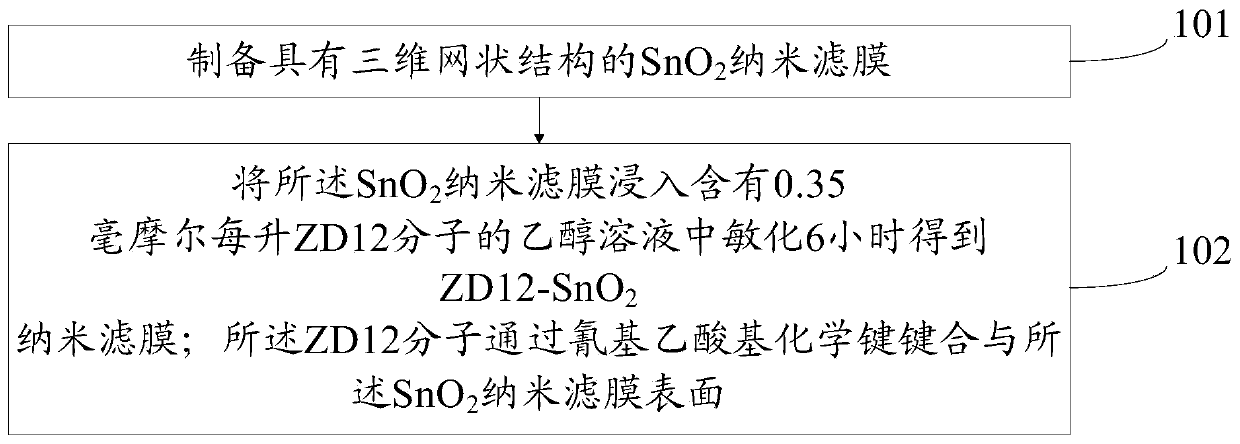

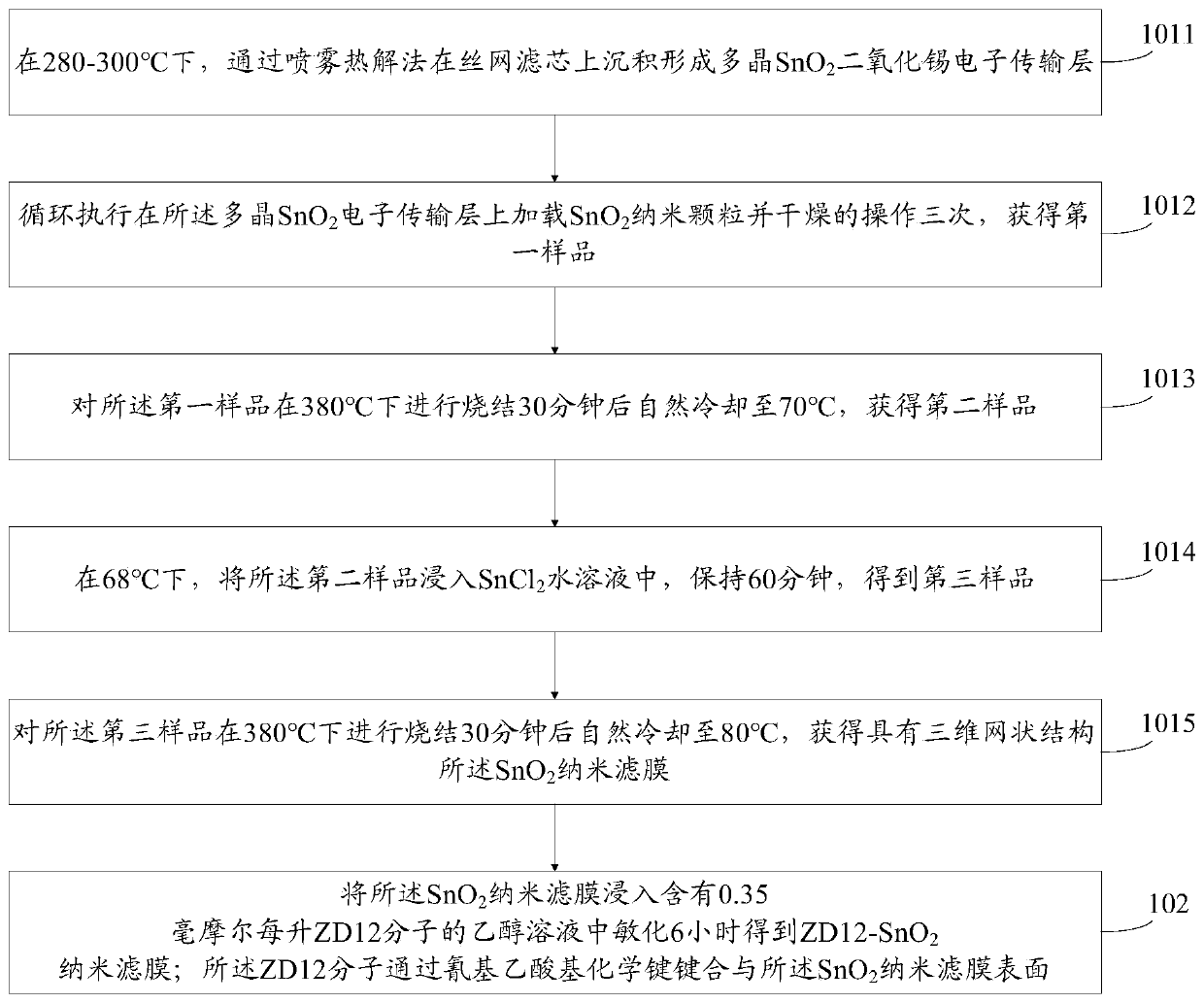

[0042] refer to figure 1 , showing a flow chart of the steps of a method for preparing a filter membrane provided by the present invention, such as figure 1 As shown, the method may include:

[0043] Step 101: Prepare SnO with a three-dimensional network structure 2 nanofiltration membrane.

[0044] In the embodiment of the present invention, based on SnO 2 High electron mobility, photocatalytic activity, chemical stability, non-toxicity and low cost, choose SnO 2 Nanofiltration membranes serve as the basis for membrane preparation. Optionally, in order to enhance the SnO 2The specific surface area of the nanofiltration membrane can prepare SnO with a three-dimensional network structure 2 nanofiltration membrane. Those skilled in the art can also select other nanofiltration membranes with a high specific surface area structure, high electron mobility, and good photocatalytic activity according to specific preparation process conditions or actual application requiremen...

example 1

[0086] Deposition of dense polycrystalline SnO on pre-cleaned stainless steel wire mesh cartridges by spray pyrolysis on a hot stage at 300 °C 2 electron transport layer. Spray precursor solution containing 0.25M SnCl 2 ethanol solution. The spray distance is 6 cm from the sample, the single spray time is 60 seconds, the number of spray cycles is 30, and the interval between each cycle is 30 seconds. By controlling the above parameters, the dense polycrystalline SnO with a thickness of about 100 nanometers is obtained. 2 Electron transport layer;

[0087] The viscous paste of SnO 2 Nanoparticles (average particle size 50 nm, diluted with 36% terpineol into a viscous paste) were loaded onto dense polycrystalline SnO by stencil printing. 2 On the electron transport layer, cycle this operation 3 times, and dry in an oven at 150°C for 15 minutes after each cycle, then place the sample in a muffle furnace for sintering at 380°C for 30 minutes, and then naturally cool to 70°C ,...

example 2

[0093] The embodiment of the present invention is also to the ZD12-SnO that above-mentioned example 1 prepares 2 The catalytic degradation performance of volatile organic compounds, such as benzene, toluene, and formaldehyde, has been studied in the photocatalytic system of nanofiltration membranes. The following takes formaldehyde as an example:

[0094] Add 100L of formaldehyde-containing air to the quartz reactor to circulate through the filter membrane, the initial formaldehyde concentration is 0.1-12mg / L, the initial humidity is 10-260%, and the formaldehyde air flow rate is 10-260m 3 / h. The adsorption experiment was carried out in the dark for 15 minutes to achieve sufficient contact between formaldehyde and photocatalyst to establish adsorption equilibrium.

[0095] Alternatively, 100L of formaldehyde-containing air can be added to the quartz reactor to circulate through the filter membrane, the initial formaldehyde concentration is 10mg / L, the initial humidity is 72%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com