Photocatalytic nano-film and preparation method thereof, and degradation method of organic matters

A nano-film and photocatalytic technology, applied in the field of photocatalysis, can solve the problems of reducing photocatalytic efficiency, limiting applications, and high economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

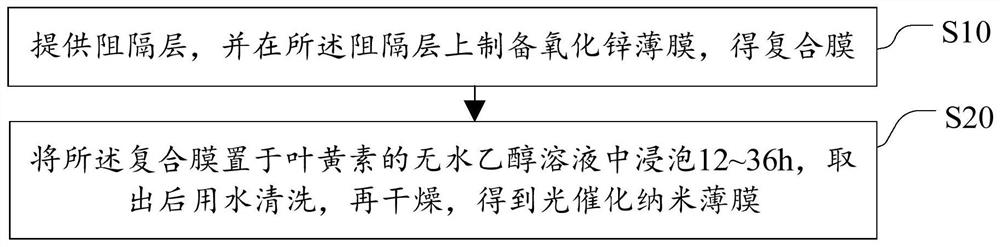

[0048] see figure 1 , the present invention further proposes a method for preparing a photocatalytic nano film as described above, comprising the following steps:

[0049] S10, providing a barrier layer, and preparing a zinc oxide thin film on the barrier layer to obtain a composite film.

[0050] This step mainly prepares a composite film including a barrier layer and a zinc oxide film. The barrier layer can be purchased or prepared by yourself. When preparing by yourself, specifically, before step S10, it also includes:

[0051] S11, using the spray pyrolysis method, under heating conditions, the Zn(NO 3 ) 2 ·6H 2 The isopropanol solution of O was sprayed onto the substrate, and the spraying was repeated several times to form a barrier layer on the substrate.

[0052] The spray pyrolysis method refers to spraying the metal salt solution into a high-temperature atmosphere in the form of a mist, which immediately causes the evaporation of the solvent and the thermal decomp...

Embodiment 1

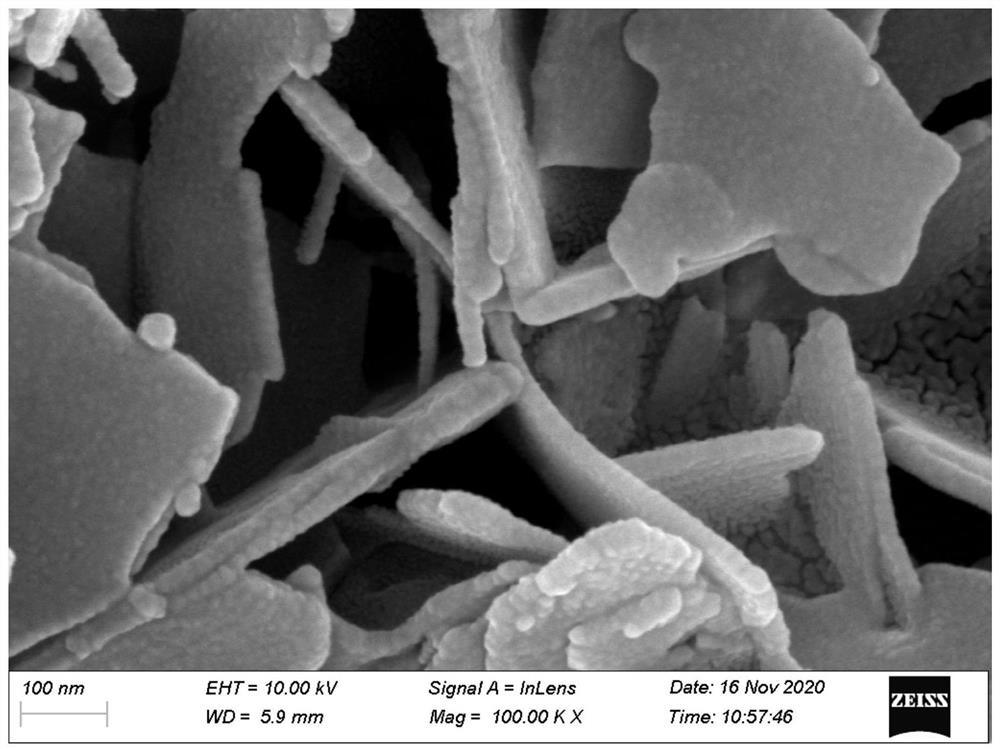

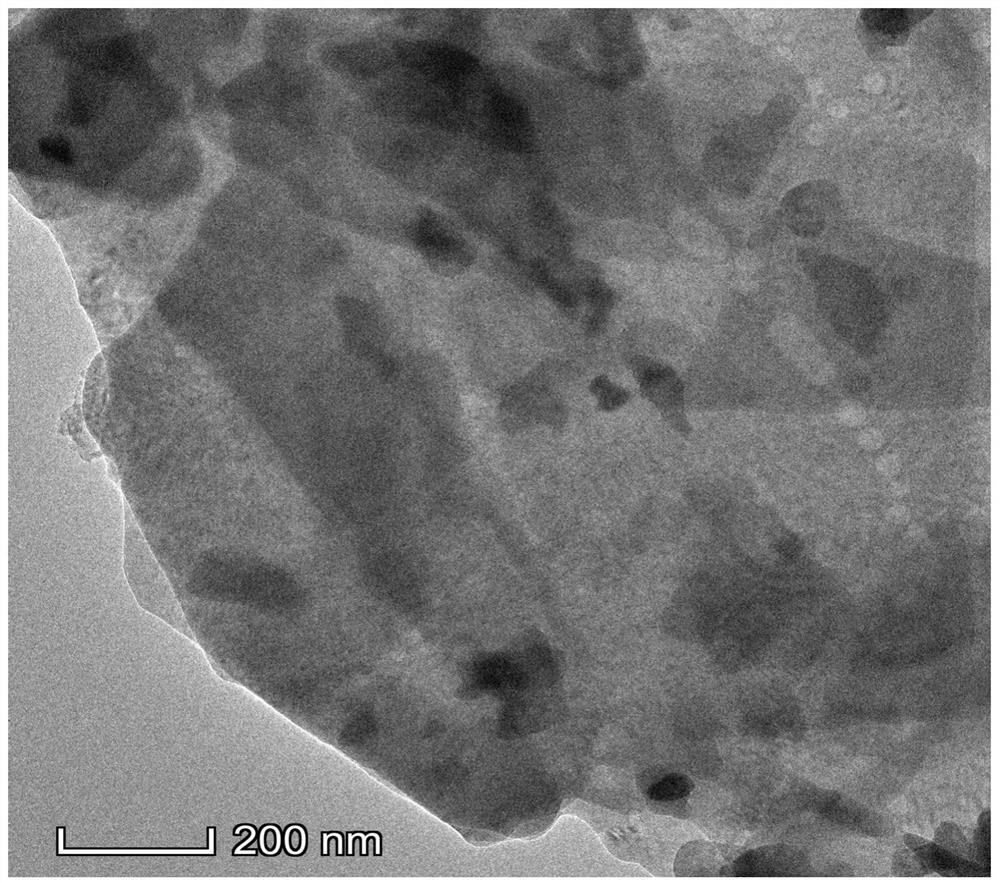

[0086] (1) Using the spray pyrolysis method, the Zn(NO 3 ) 2 ·6H 2 The isopropanol solution of O is sprayed onto the substrate, the single spraying time is 20s, and the spraying is repeated 10 times, and the time interval between two adjacent sprayings is 60s to form a barrier layer;

[0087] (2) Colloidal nano-zinc oxide is scraped onto the barrier layer and dried at 120°C for 30 minutes; after repeating the above steps 3 times, calcined at 500°C for 90 minutes and cooled to 50°C to obtain a semi-finished product; place the semi-finished product Zn(NO at 30mmol / L 3 ) 2 ·6H 2 O aqueous solution, and soaked at 60°C for 60min, washed and calcined at 500°C for 90min to form a zinc oxide film on the barrier layer, and separate the barrier layer and the zinc oxide film from the substrate as a whole peeled off to obtain a composite film;

[0088] (3) Soak the composite film in an absolute ethanol solution of lutein for 24 hours, take it out, wash it with ultrapure water, and d...

Embodiment 2

[0091] (1) Using the spray pyrolysis method, the Zn(NO 3 ) 2 ·6H 2 The isopropanol solution of O is sprayed onto the substrate, the single spraying time is 10s, and the spraying is repeated 5 times, and the time interval between two adjacent sprayings is 30s to form a barrier layer;

[0092] (2) Colloidal nano-zinc oxide is scraped onto the barrier layer, dried at 80°C for 40min; after repeating the above steps 5 times, calcined at 400°C for 120min, cooled to 40°C to obtain a semi-finished product; In Zn(NO 3 ) 2 ·6H 2 O aqueous solution, after soaking at 80°C for 30min, cleaning and calcining at 400°C for 120min, forming a zinc oxide film on the barrier layer, and removing the barrier layer and the zinc oxide film as a whole from the substrate peeled off to obtain a composite film;

[0093] (3) Soak the composite film in an absolute ethanol solution of lutein for 12 hours, take it out, wash it with ultrapure water, and dry it with compressed air to obtain a photocatalyt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com