Preparation method and application of novel gas diffusion electrode

A gas diffusion electrode, a new type of technology, applied in the direction of electrodes, electrode shape/type, electrolysis process, etc., can solve the problems of increasing production costs, and achieve the effect of facilitating migration, good conductivity, and avoiding stability problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

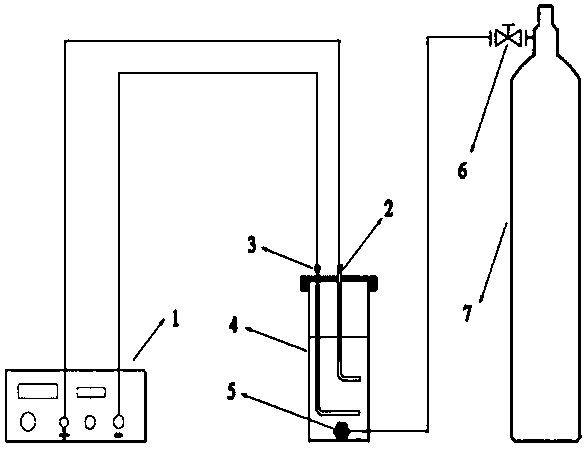

Method used

Image

Examples

Embodiment 1

[0041] Cut a stainless steel mesh with a specification of 8cm*8cm*0.1mm and place it in a beaker, add 15ml of 0.05mol / L sodium hydroxide solution and 15ml of 0.05mol / L phosphoric acid solution into the beaker, heat to 90°C and keep it for 20min before use .

[0042] Weigh 25g of graphite powder into a beaker, add 800ml of water, boil and keep boiling for 1h. After cooling, wash with distilled water for later use.

[0043] Weigh 20g of graphite powder, 2g of zirconia and mix evenly, add 20ml of acetone solution, place the beaker in ultrasonic vibration for 10min, so that the graphite, zirconia powder and acetone are evenly mixed. Add 2ml of polytetrafluoroethylene solution and continue shaking for 20min. Place the oscillating beaker in a 70°C water bath to continuously volatilize the acetone to form a paste, which is evenly coated on the treated stainless steel mesh to form a gas diffusion layer, which will cover the gas The stainless steel mesh of the diffusion layer was ca...

Embodiment 2

[0045] Cut a stainless steel mesh with a specification of 8cm*8cm*0.1mm and place it in a beaker, add 15ml of 0.05mol / L sodium hydroxide solution and 15ml of 0.05mol / L phosphoric acid solution into the beaker, heat to 90°C and keep it for 20min before use .

[0046] Weigh 25g of graphite powder into a beaker, add 800ml of water, boil and keep boiling for 1h. After cooling, wash with distilled water for later use.

[0047] Weigh 20g of graphite powder, 4g of zirconia and mix evenly, add 20ml of acetone solution, place the beaker in an ultrasonic wave and vibrate for 10min, so that the graphite, zirconia powder and acetone are evenly mixed. Add 3ml of polytetrafluoroethylene solution and continue shaking for 20min. Place the oscillating beaker in a 90°C water bath to continuously volatilize the acetone to form a paste, which is evenly coated on the treated stainless steel mesh to form a gas diffusion layer, which will cover the gas The stainless steel mesh of the diffusion la...

Embodiment 3

[0049] Cut a stainless steel mesh with a specification of 8cm*8cm*0.1mm and place it in a beaker, add 15ml of 0.05mol / L sodium hydroxide solution and 15ml of 0.05mol / L phosphoric acid solution into the beaker, heat to 90°C and keep it for 20min before use .

[0050] Weigh 25g of graphite powder into a beaker, add 800ml of water, boil and keep boiling for 1h. After cooling, wash with distilled water for later use.

[0051] Weigh 20g of graphite powder, 6g of zirconia and mix evenly, add 20ml of acetone solution, place the beaker in an ultrasonic wave and vibrate for 10min, so that the graphite, zirconia powder and acetone are evenly mixed. Add 3ml of polytetrafluoroethylene solution and continue shaking for 20min. Place the oscillating beaker in an 80°C water bath to continuously volatilize the acetone to form a paste, which is evenly coated on the treated stainless steel mesh to form a gas diffusion layer, which will cover the gas The stainless steel mesh of the diffusion l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com