Glass substrate positioning apparatus, positioning method, edge plane polishing apparatus and edge plane polishing method

A glass substrate and positioning device technology, applied in positioning devices, grinding workpiece supports, grinding/polishing equipment, etc., can solve the problems of poor processing efficiency, difficulty in moving to the correct position, blocking member glass substrate stuck, etc. , to achieve the effects of shock mitigation, high-precision positioning, and inhibition of premature wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, since the end surface grinding apparatus provided with the positioning device of this embodiment is the same as the structure shown in FIG. 4 and FIG. 5 already demonstrated, illustration and description are abbreviate|omitted.

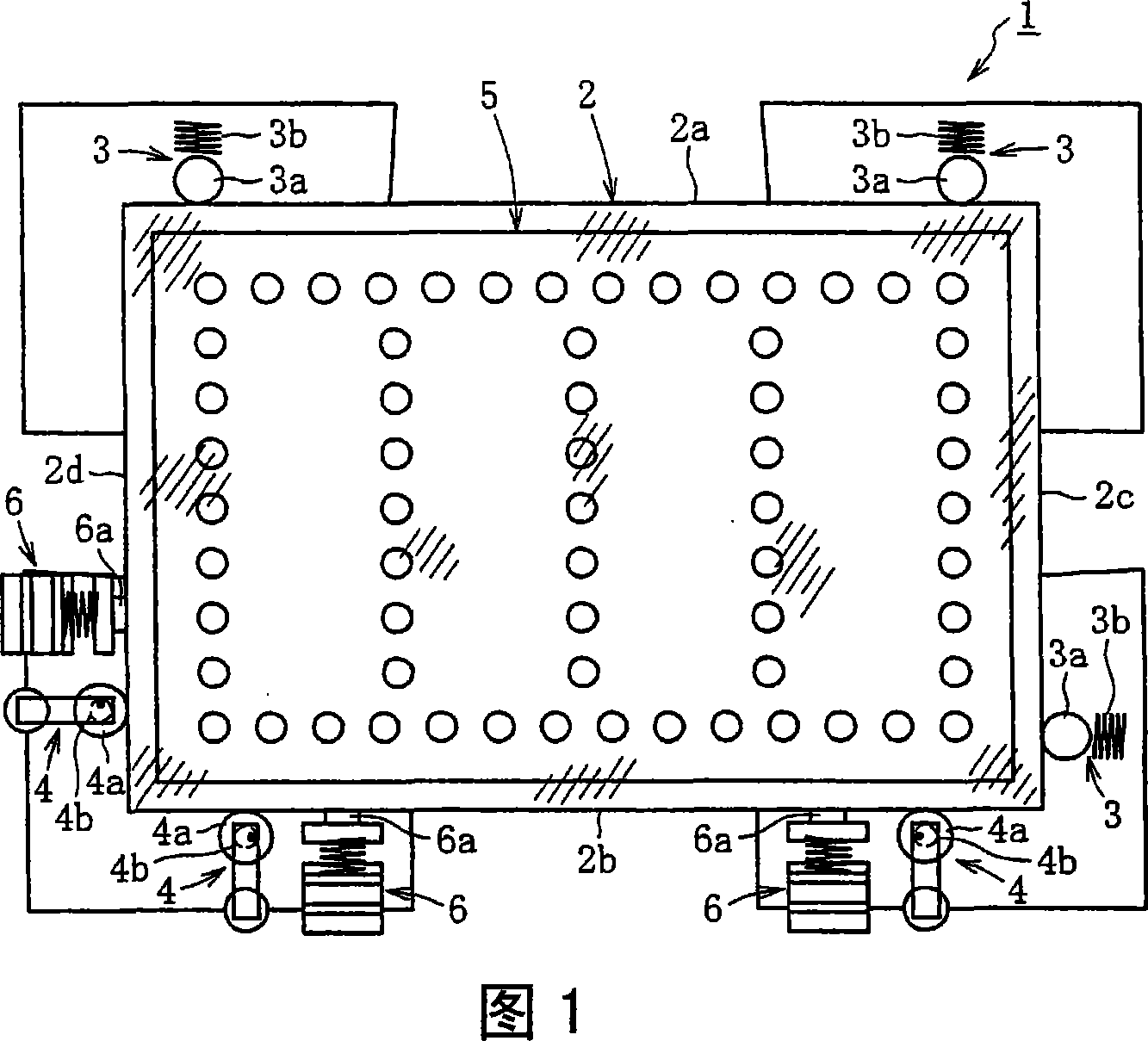

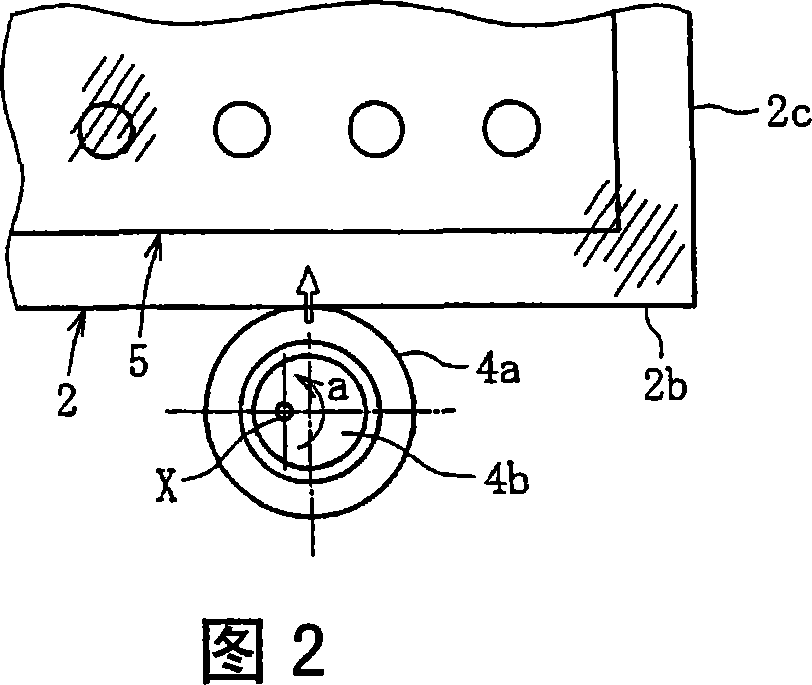

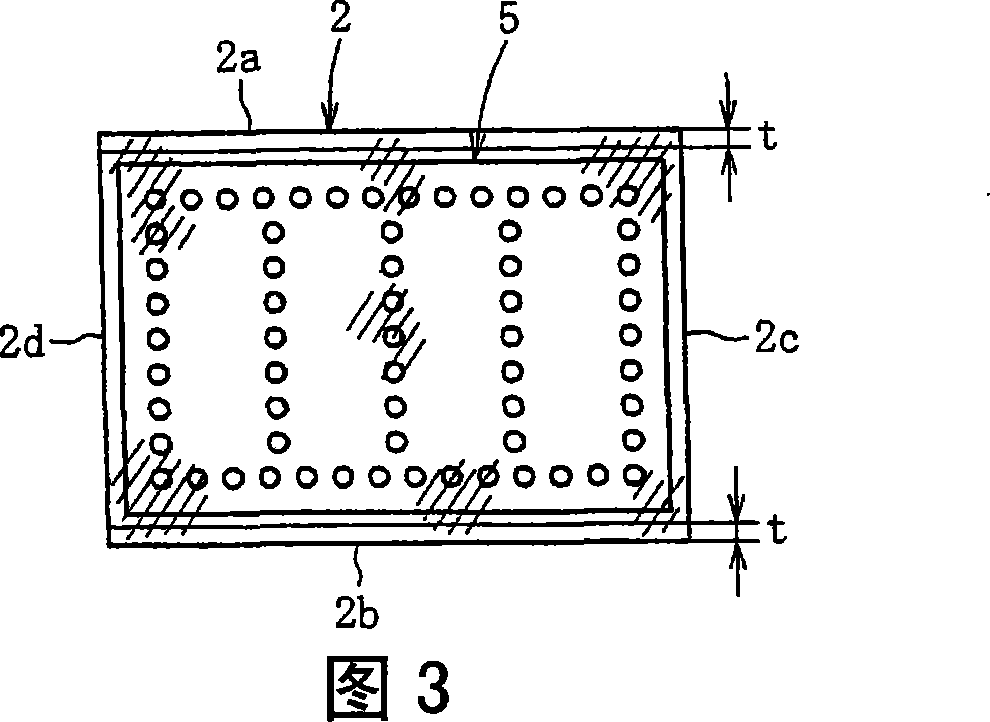

[0050] As shown in FIG. 1 , the positioning device 1 of this embodiment basically includes: a blocking member 3 capable of abutting against one side 2a (2c) of the glass substrate 2; 2d) The pressing member 4 that abuts and pushes the glass substrate 2 to the blocking member 3 side, the blocking member 3 is set to be able to move following the pushing of the glass substrate 2, and the pressing member 4 is on one side 2a (2c) of the glass substrate 2 ) is in contact with the stopper member 3, the positioning of the glass substrate 2 is performed with reference to the displacement amount of the other side 2b (2d) of the glass substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com