Mechanical flexibility space buttjunction platform

A technology of space docking and docking platform, applied in the direction of workbench, manufacturing tools, etc., can solve the problems of workpiece damage, inflexibility of docking platform, and misalignment of the geometric center of slide rail and chute, so as to avoid injury and improve space docking. Quality and docking effect, easy operation control and assembly and disassembly maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

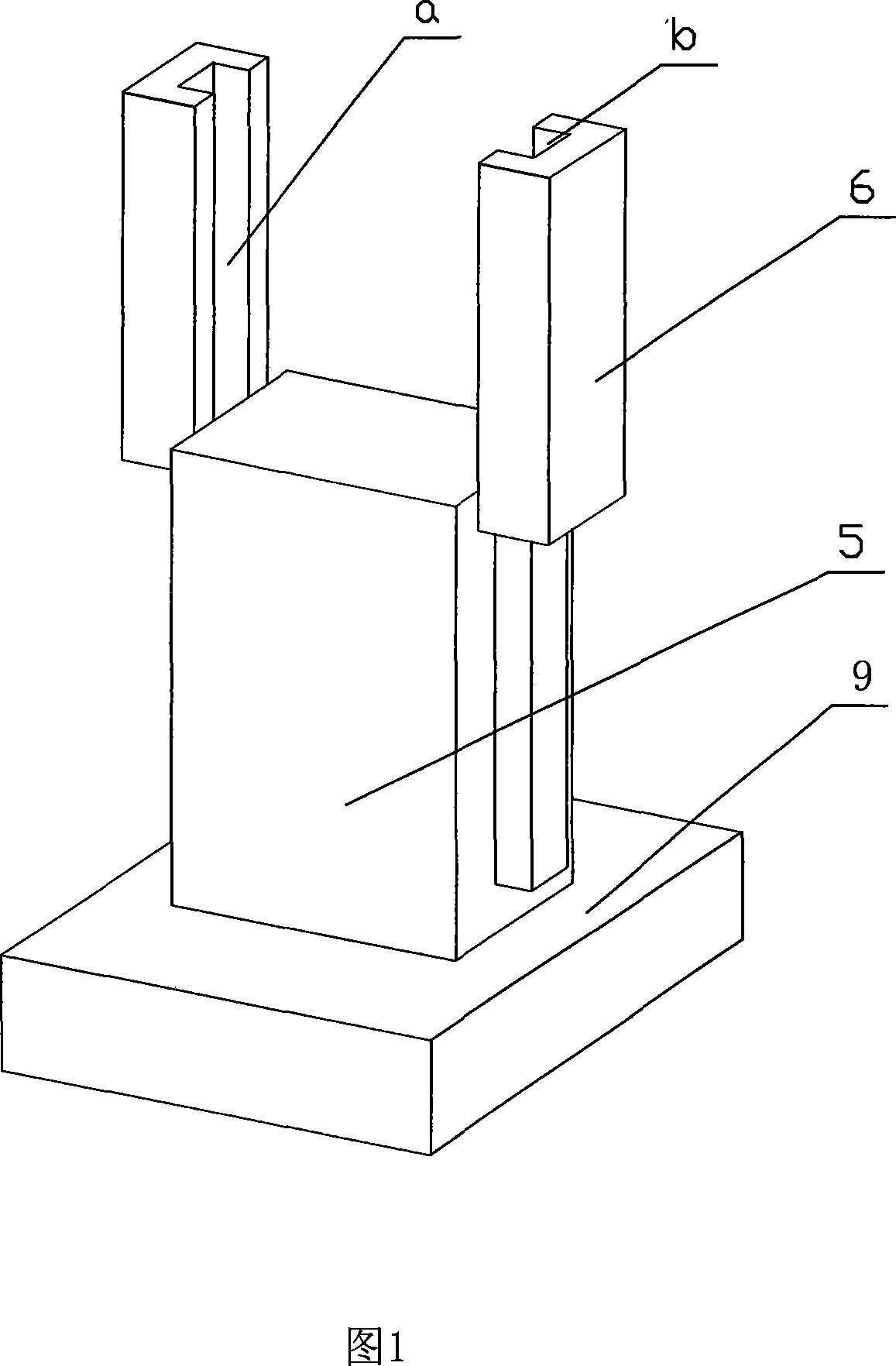

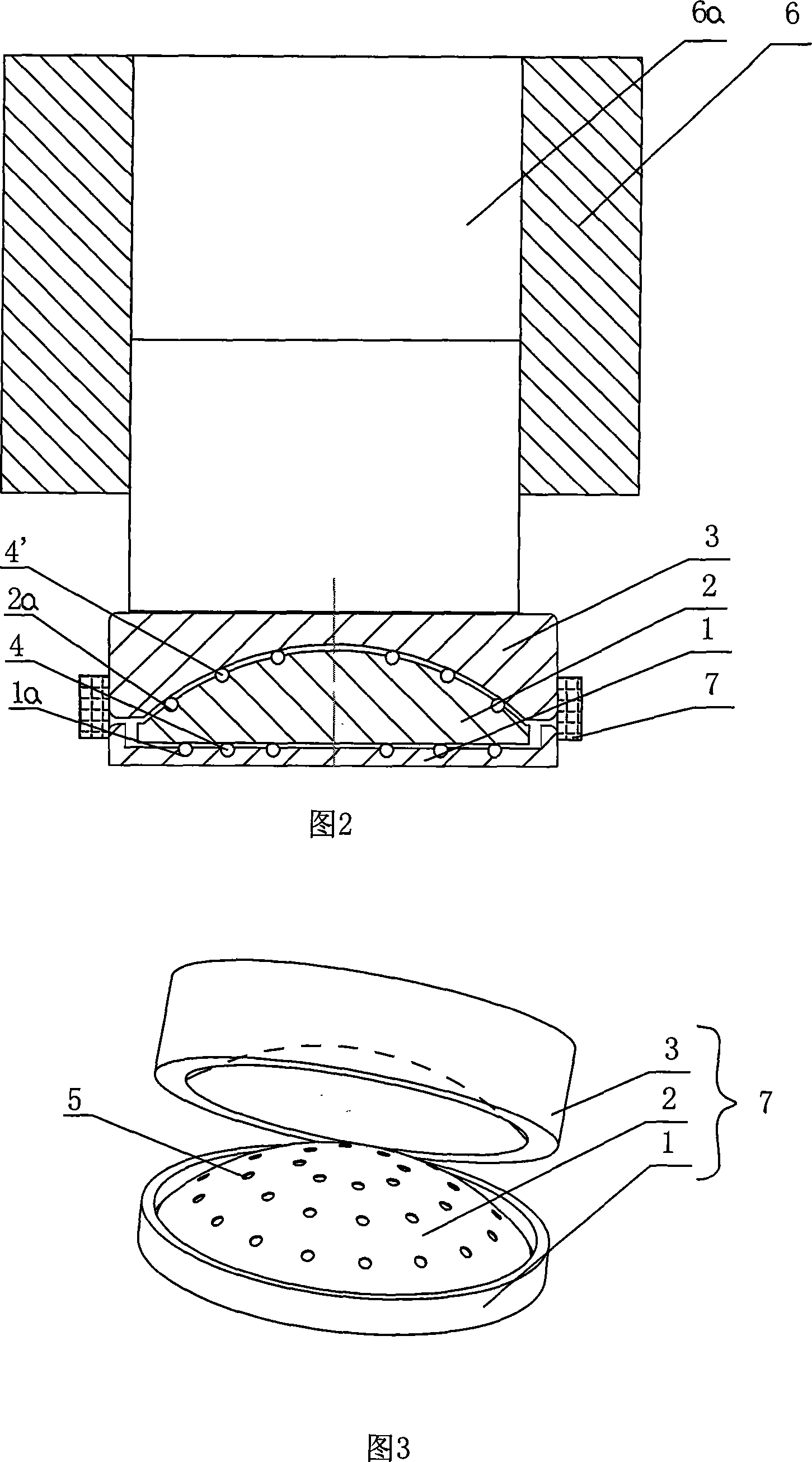

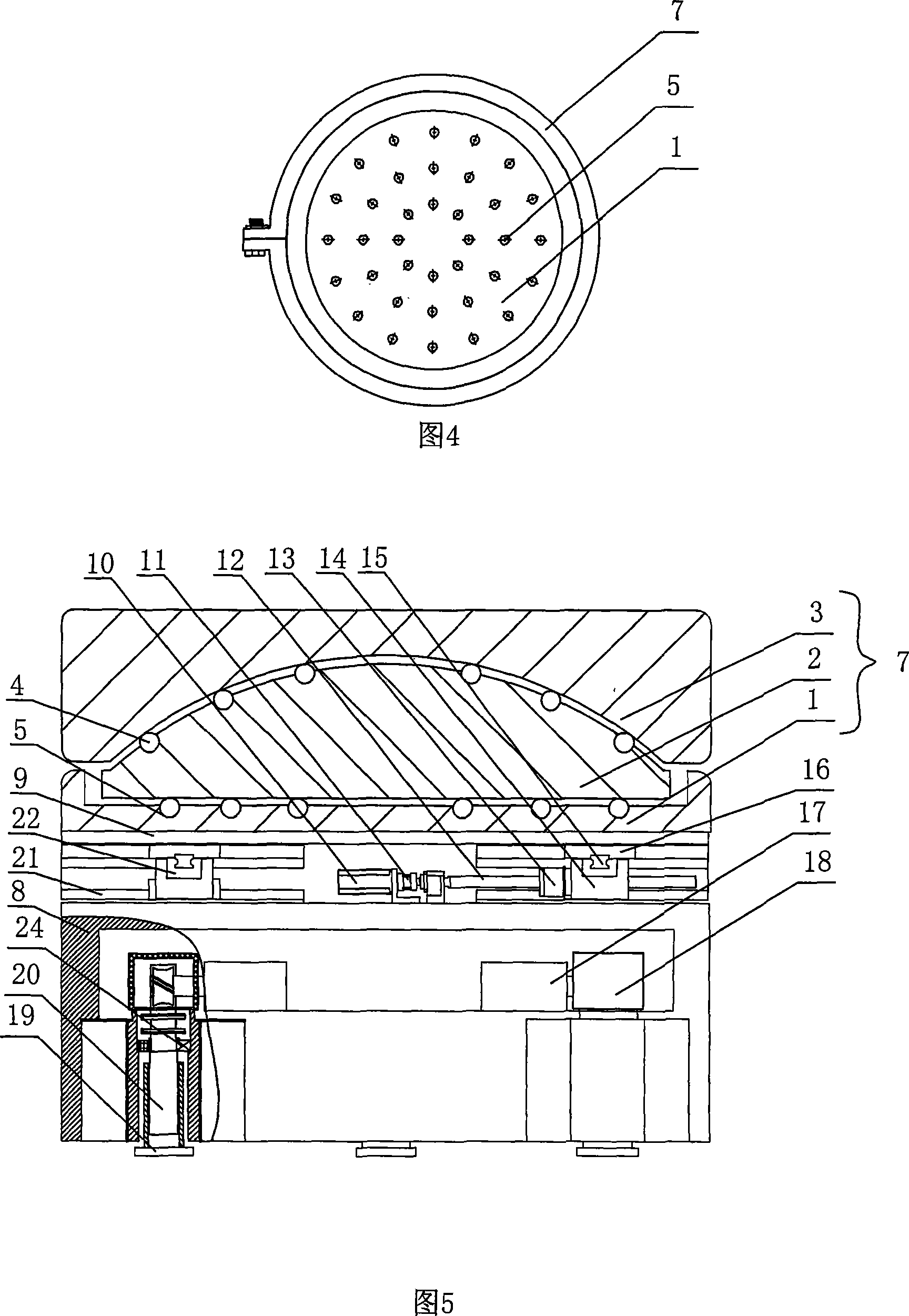

[0037]As shown in Figures 2, 3, and 4: a mechanical flexible space docking platform is provided with a mechanical flexible assembly platform installed on a mechanical self-adjusting docking platform, wherein the mechanical flexible assembly platform consists of a base 1, a joint Body 2 and floating body 3, wherein the upper end of the base 1 is provided with a circular groove, and spherical pits 1a are evenly distributed in the circular grooves, balls 4 are installed in the spherical pits 1a, and the joint body 2 is a small A semi-spherical body, the bottom plane of the small semi-spherical body is located in the circular groove of the base 1 and contacts the ball 4, and spherical pits 2a are evenly distributed on the surface of the spherical cap, and the spherical pits 2a are equipped with The ball 4' covers the floating body 3 above the joint body 2, and the bottom surface of the floating body 3 is provided with an arc-shaped groove compatible with the surface of the spherica...

Embodiment 2

[0058] This embodiment 2 is consistent with embodiment 1 structure, and its difference is:

[0059] The joint body 2 is a small semi-spherical body, and the bottom plane of the small semi-spherical body is located in the circular groove of the base 1 and is in sliding contact with it.

Embodiment 3

[0061] This embodiment 3 is consistent with embodiment 1 structure, and its difference is:

[0062] The joint body 2 is covered with a floating body 3 , and the bottom surface of the floating body 3 is provided with an arc-shaped groove adapted to the surface of the spherical cap of the joint body 2 , and is in sliding contact with the joint body 2 .

[0063] Its working principle is:

[0064] The workpiece 5 is installed on the upper surface of the floating body 3, and the workpiece 5 extends into the cavity 6a of the docking body 6 to be docked with it. The two can be over-fit, interference fit or clearance fit. During the alignment stroke Torsion occurs when a slight deviation occurs. When the workpiece 5 and the floating body 3 are squeezed, the workpiece 5 drives the floating body 3 to rotate and slide at any angle on the joint body 2 in the direction of the force. At the same time, it can also drive the joint Body 2 slides on base 1 . The whole docking process can also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com