Method for winding heater wire disk of electromagnetic heater

A winding method and heating wire technology, applied in induction heating, induction heating devices, coil devices, etc., can solve the problems of weakening magnetic field strength, hot oil splashing, limited application range of induction cookers, etc., and achieve the effect of obvious effect and uniform heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

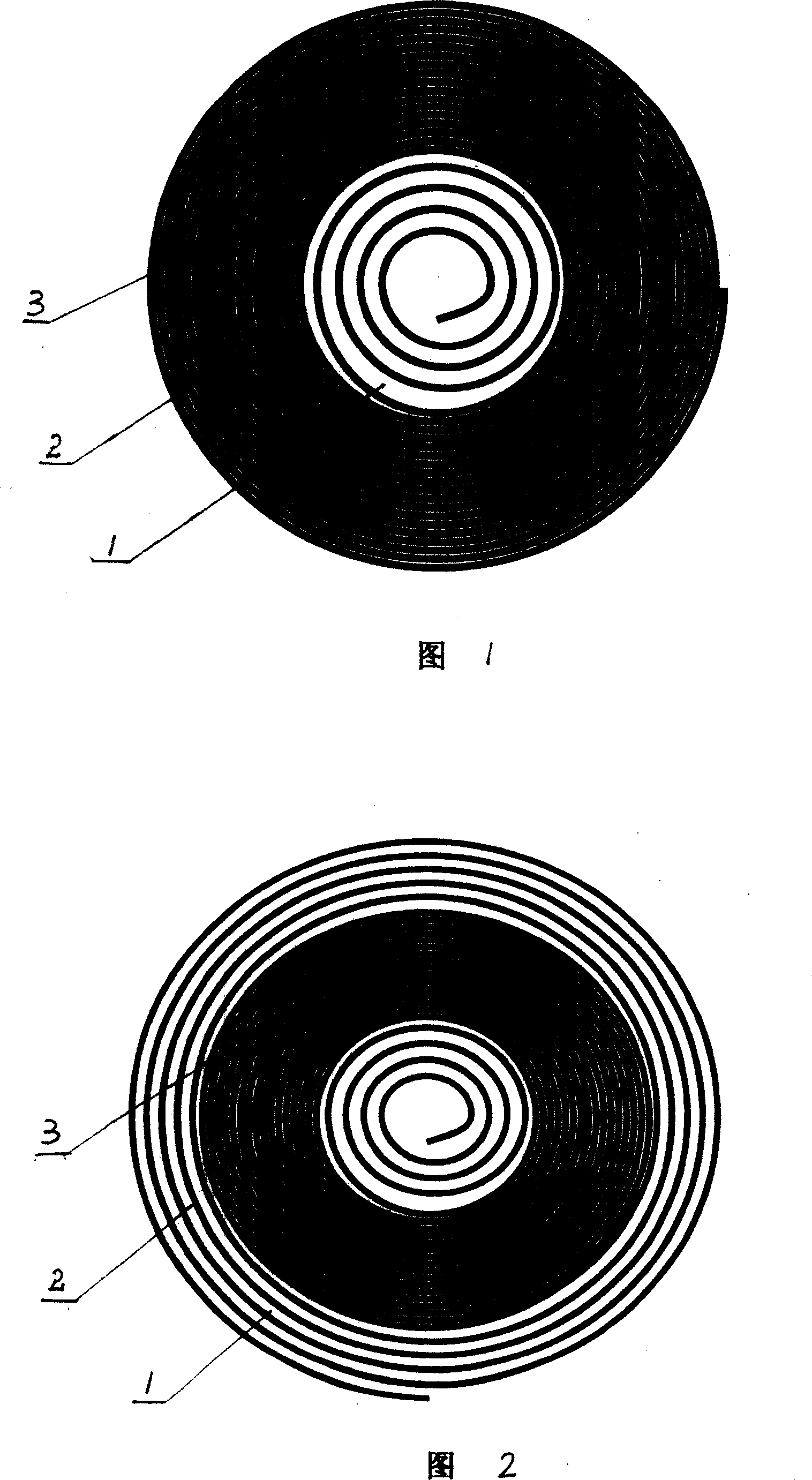

Embodiment 1

[0026] Embodiment 1. As shown in Figure 1, the induction cooker heating reel 3 is formed by winding the heating wire 2 in circles, and there is a gap 1 between the heating wire 2 at the center of the heating reel 3. 1 has a size of 0.5 mm to 5 mm. The heating wires 2 of the heating wire reel 3 are distributed in a state of being thin in the center and dense in the outer ring.

Embodiment 2

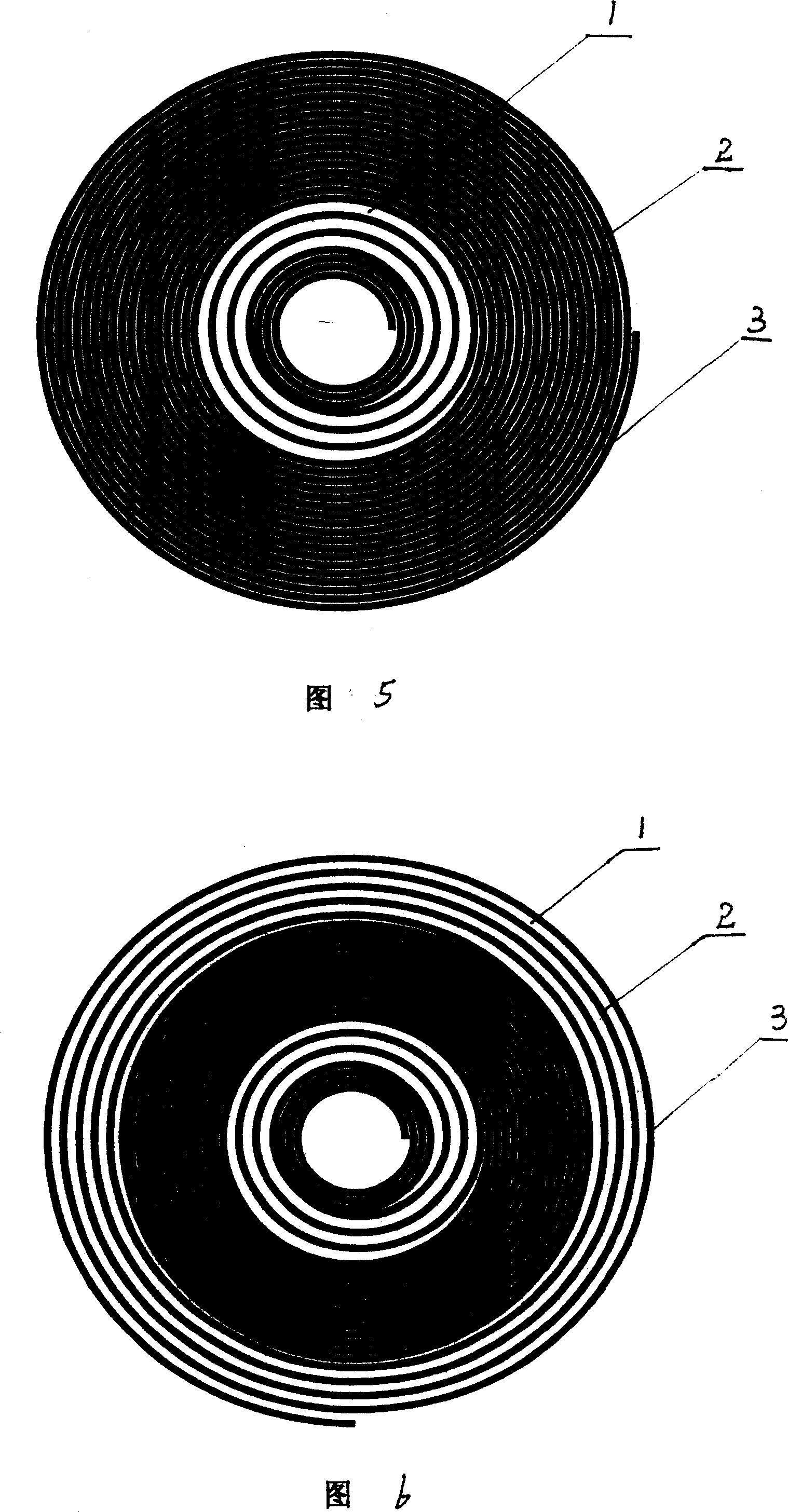

[0027] Embodiment 2, as shown in Figure 2, Figure 9, and Figure 10, there is a gap 1 between the lines of the heating wire 2 at the center of the heating wire reel 3 and the outer ring, and the heating wire 2 of the heating wire reel 3 It is sparse inside and outside, and densely distributed in the middle; the shape of the heating coil 3 is a plane coil or an arc coil. .

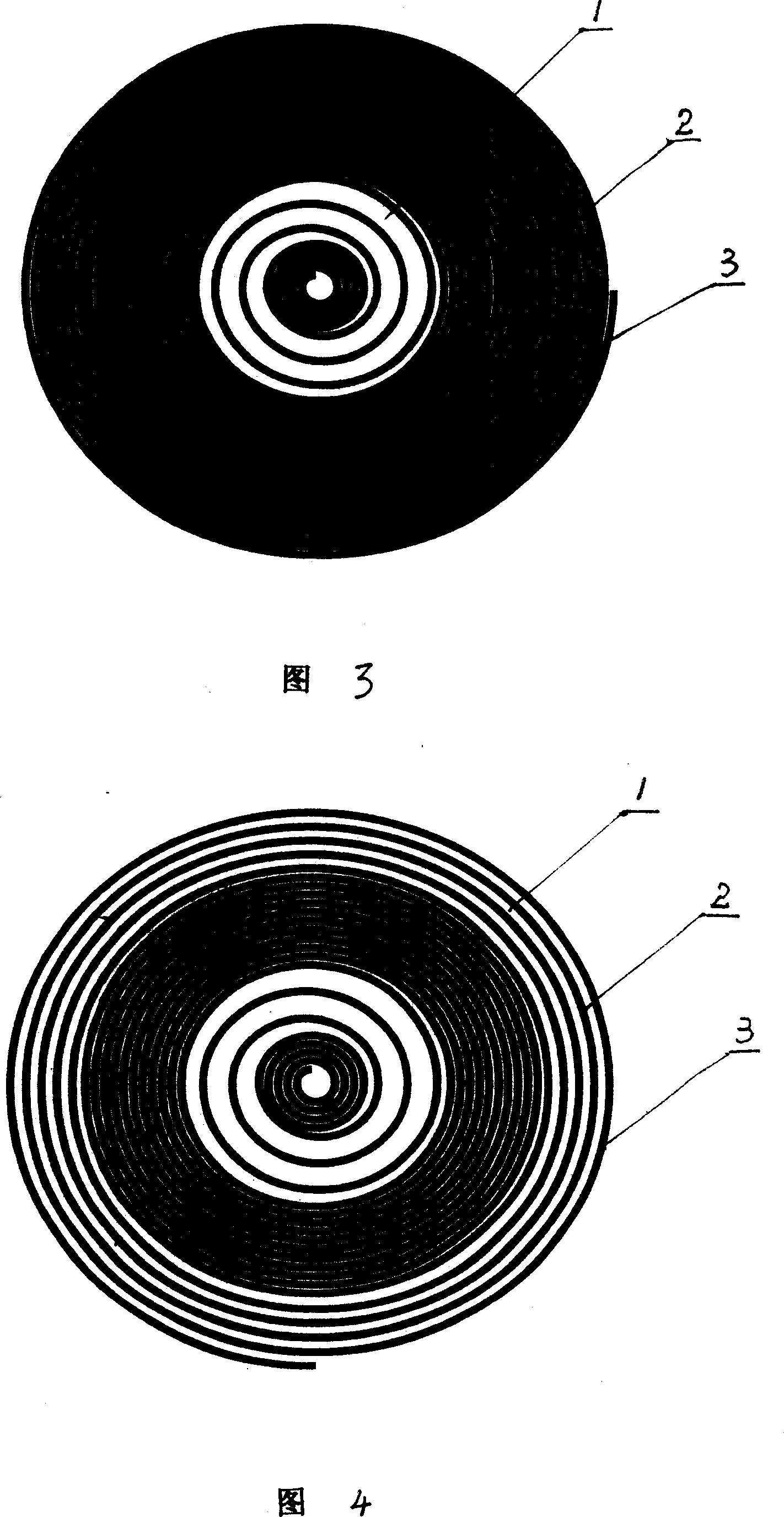

Embodiment 3

[0028] Embodiment 3. As shown in FIG. 3 , the heating wire 2 is densely wound 2 to 5 times at the center of the heating coil 3 , and then distributed in a state of sparseness and then dense winding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com