Stamper attaching apparatus and thermal transfer press machine

A technology for installing devices and pressure equipment, applied to other household appliances, optical components, household appliances, etc., can solve problems such as inability to ensure fluid passages, heating of metal molds, poor cooling efficiency, and long forming cycles, and achieve manufacturing. Simple, maintain stable performance, and simplify the composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

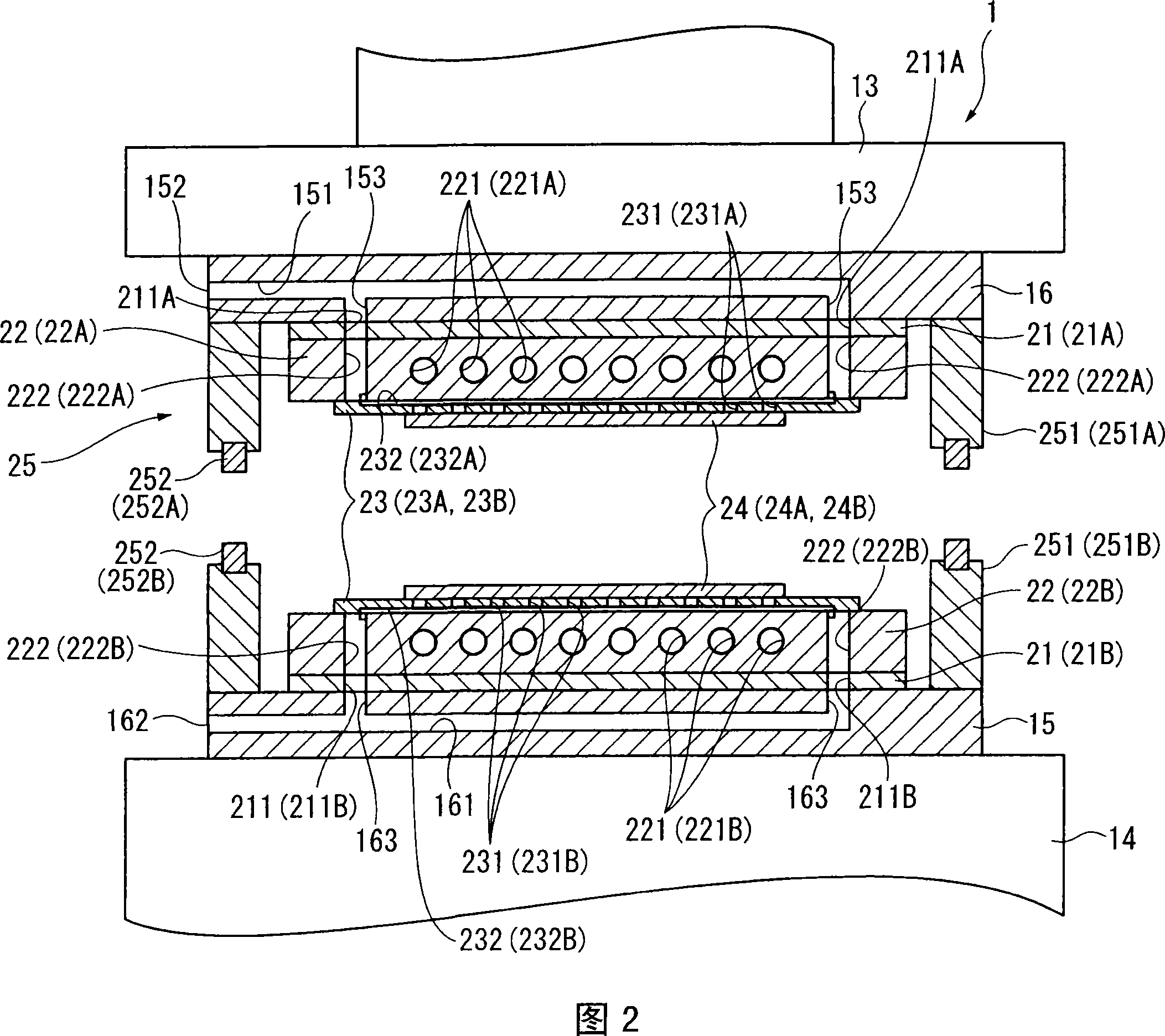

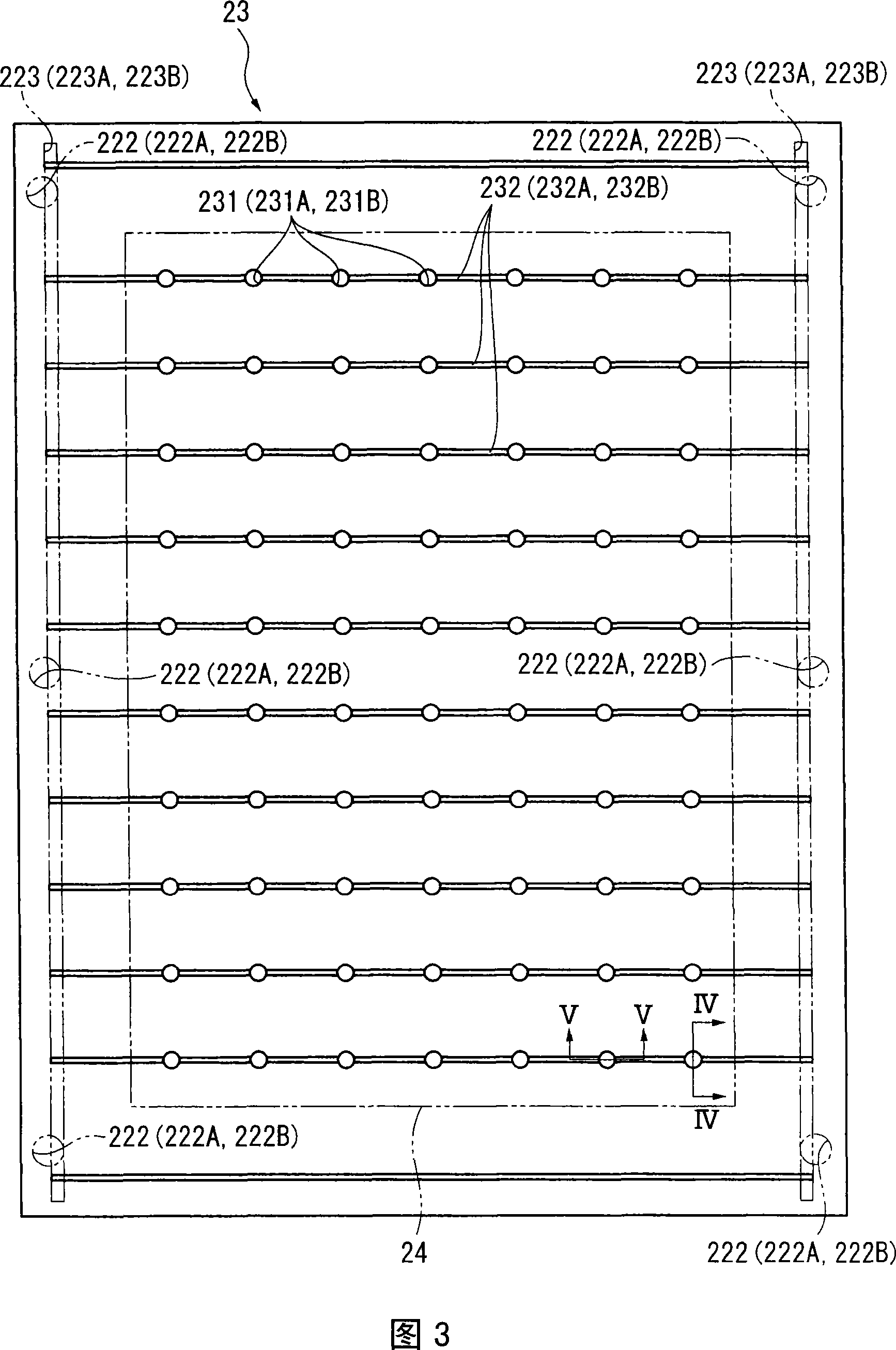

[0028] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

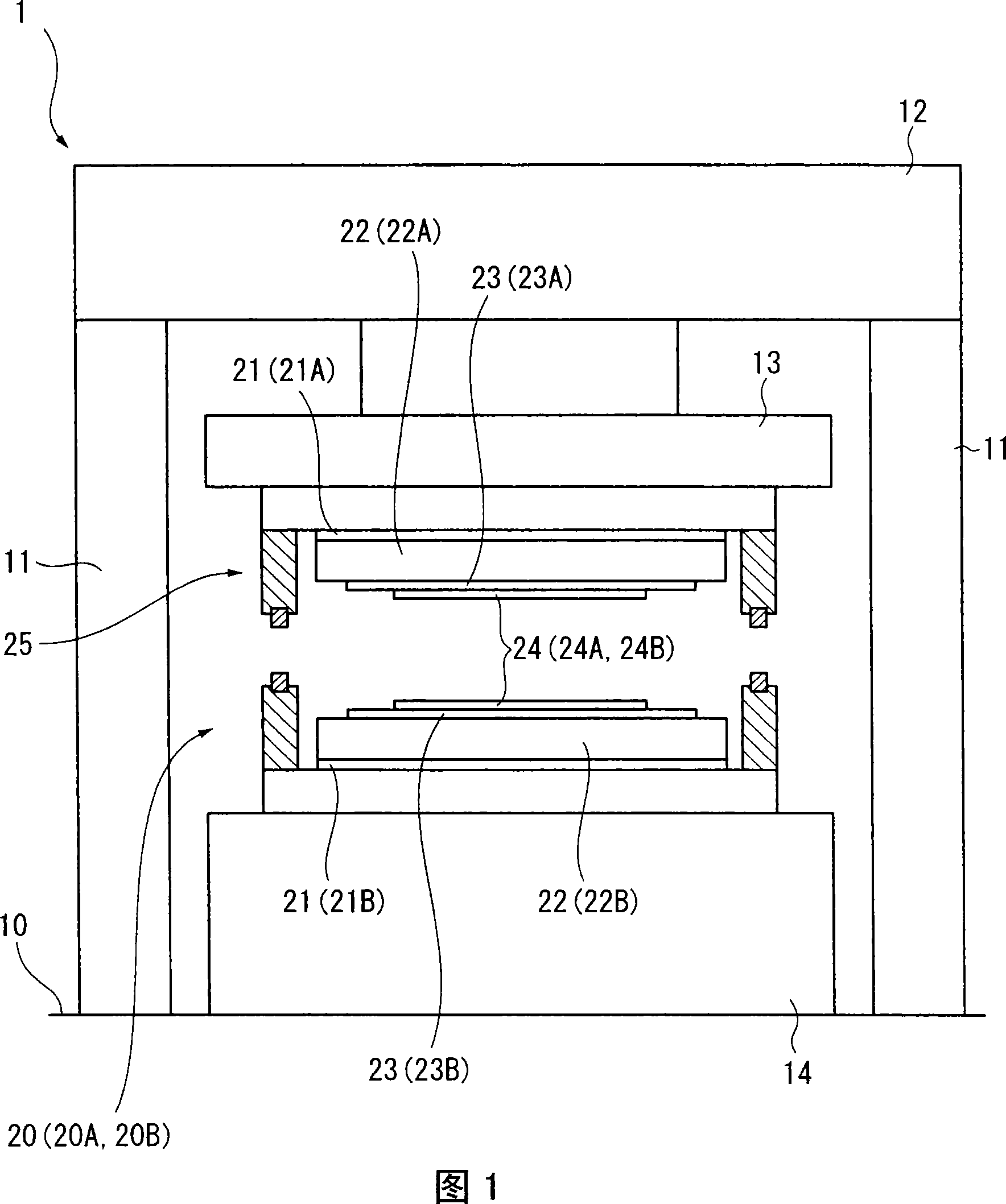

[0029] FIG. 1 is a front view showing a thermal transfer pressure device 1 according to an embodiment of the present invention. In this embodiment, the thermal transfer pressure device 1 is a device for manufacturing a light guide plate used in a backlight of a liquid crystal display by thermally transferring a concave-convex pattern onto a substrate.

[0030] In Fig. 1, the thermal transfer pressure device 1 includes: 4 columns 11 (two of which are illustrated in Fig. 1 ) erected on the base 10, a beam 12 arranged on the column 11, and a beam 12 arranged below the beam 12. The slide block 13, the cushion block 14 opposite to the slide block 13 and arranged on the base 10, the stamper installation device 20 (20A) which is arranged under the slide block 13 and installs the stamper 24 (24A), is arranged on the cushion block 14 and a stamper mounting device 20 (20B) for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com