Recombination device

A technology of recombination and catalytic body, applied in the field of recombination devices, can solve the problems of adverse effects on recombination efficiency of recombiners, complicated and expensive production of recombiners, functional failure and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

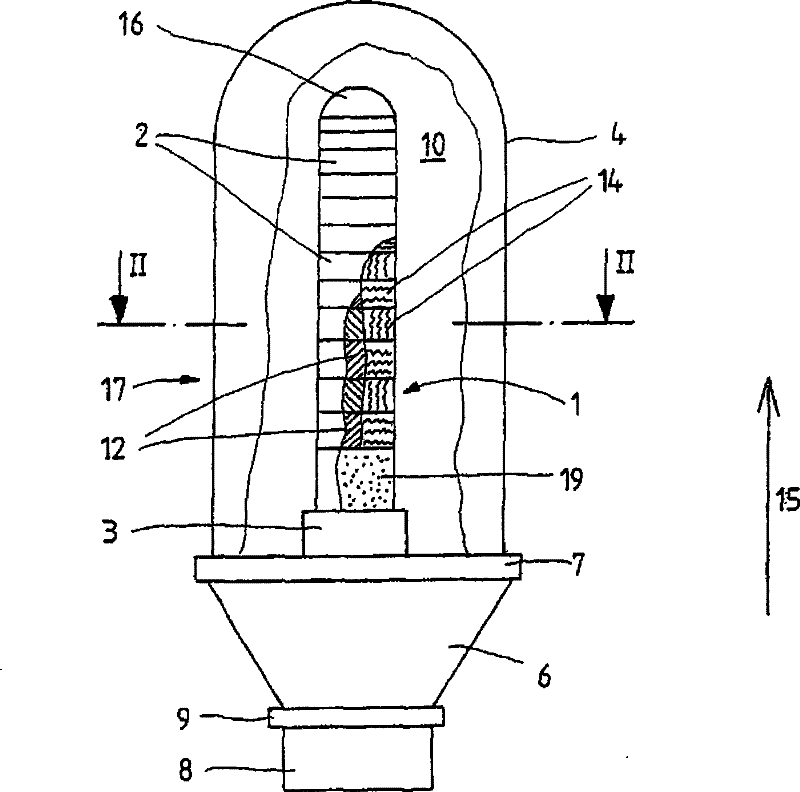

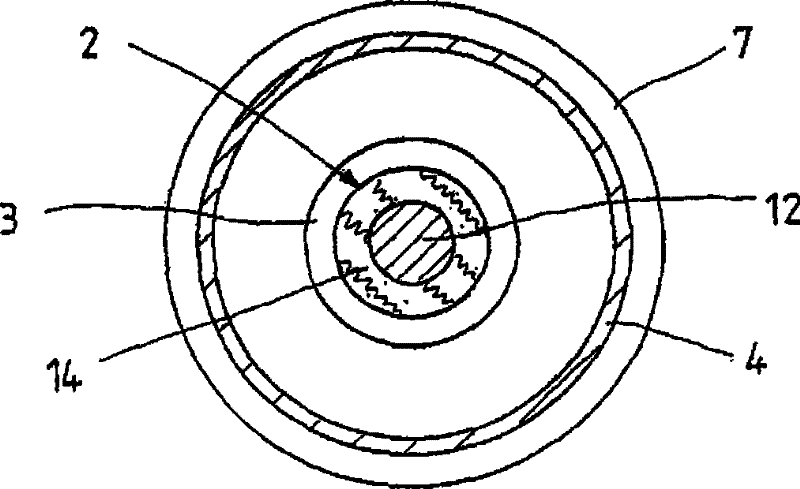

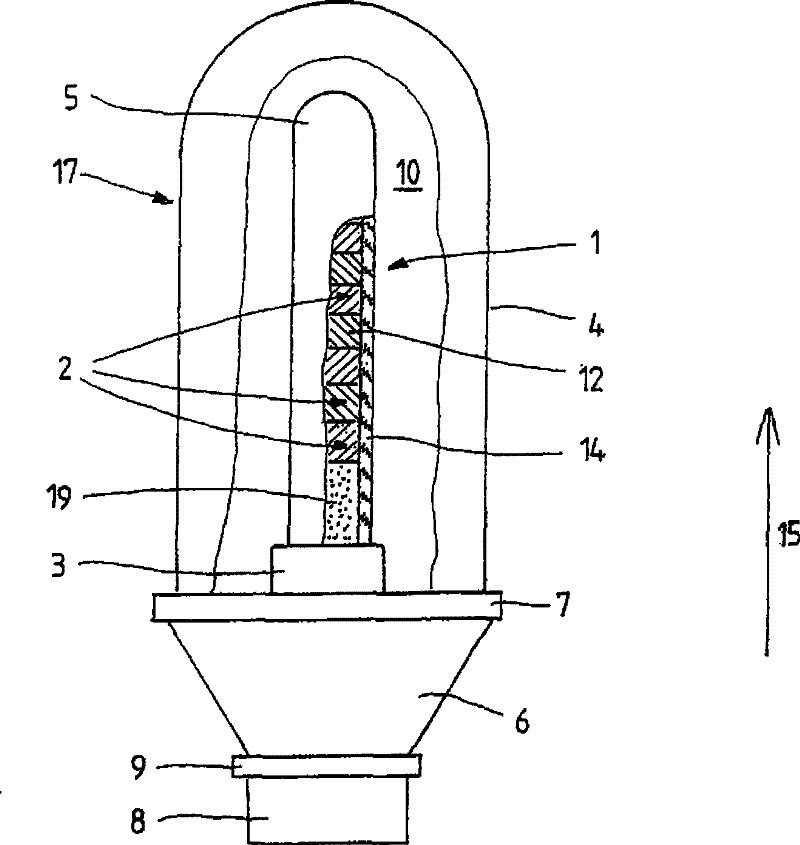

[0036] figure 1 A recombiner 17 with a recombiner device 1 according to the invention is shown in partial sectional side view. The recombiner 17 is formed in a manner known per se from a connecting pipe 8 , a connecting pipe 6 above the connecting pipe in the vertical direction 15 , a container 4 made of gas-impermeable material, and a sealing ring 7 connecting the container 4 to the connecting pipe 6 . A flange not shown in the figure can be molded on the connecting pipe 8, so that the recombiner 17 is arranged on the battery port of the battery not shown in the figure in a card-type connection. The mounting flange 9 arranged on the connecting pipe 8 along the vertical direction 15 can be used to accommodate a sealing ring not shown in the figure. Furthermore, the recombiner unit 1 can have flashover safety devices (not shown), for example in the form of melts or valves. Such flashback safety can be part of an exhaust duct not shown in the figure.

[0037] Inside the volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com