Method for modifying ultra-fine silicon dioxide

An ultra-fine silica, modified technology, applied in the treatment of dyed low molecular organic compounds, fibrous fillers, etc., can solve the problems of small particle size, large specific surface area, and decreased mechanical properties of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

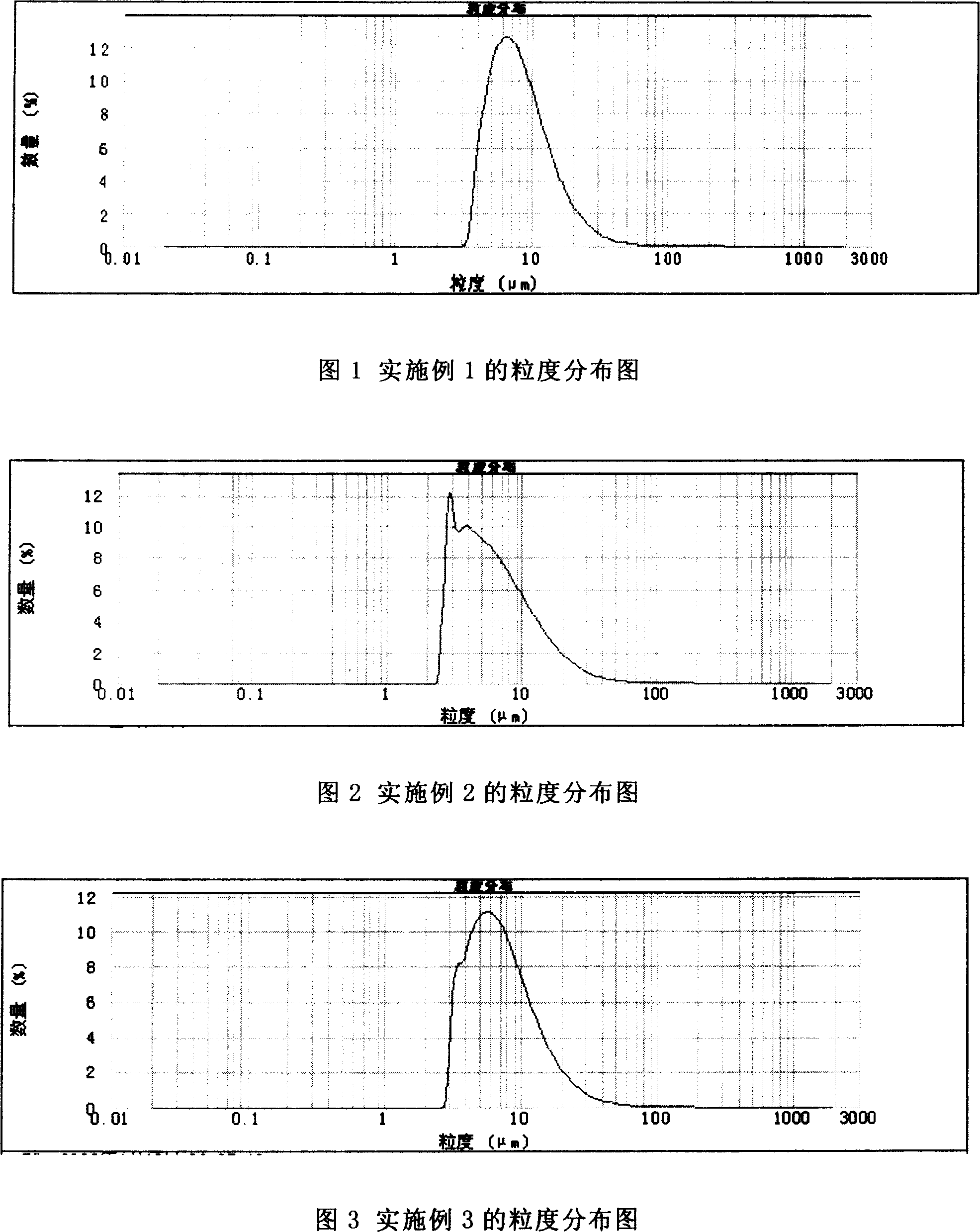

Embodiment 1

[0011] (1) Prepare 14% water glass solution in a three-necked flask, place it in a water bath at a constant temperature of 85°C, start to add 1mol / L sulfuric acid solution at 85°C dropwise with a dropping funnel, and add it at a rate of about 4-5mL / min, Stir vigorously, and measure the change of pH value of the reaction solution with wide pH value test paper. When the pH value reaches 8-9, stop adding dilute sulfuric acid dropwise, stir and age for about 2 hours, and the aging temperature is 85°C;

[0012] (2) Filtrate the resulting sol while it is hot, and repeatedly wash it several times with deionized water, and wash it with 5% BaCl 2 The solution identifies whether there are sulfate ions in the washed water, and after washing, filter to obtain orthosilicate gel;

[0013] (3) Stir the filtered and washed ortho silicic acid gel with an appropriate amount of n-butanol evenly, then transfer the mixture to a 500mL three-necked flask, heat for azeotropic distillation, and after ...

Embodiment 2

[0016] (1) Prepare 14% water glass solution in a three-necked flask, place it in a water bath at a constant temperature of 85°C, start to add 1mol / L sulfuric acid solution at 85°C dropwise with a dropping funnel, and add it at a rate of about 4-5mL / min, Stir vigorously, and measure the change of pH value of the reaction solution with wide pH value test paper. When the pH value reaches 8-9, stop adding dilute sulfuric acid dropwise, stir and age for about 2 hours, and the aging temperature is 85°C;

[0017] (2) Filtrate the resulting sol while it is hot, and repeatedly wash it several times with deionized water, and wash it with 5% BaCl 2 The solution identifies whether there are sulfate ions in the washed water, and after washing, filter to obtain orthosilicate gel;

[0018] (3) Stir the filtered and washed ortho silicic acid gel with an appropriate amount of n-butanol evenly, then transfer the mixture to a 500mL three-necked flask, heat for azeotropic distillation, and after ...

Embodiment 3

[0022] (1) Prepare 14% water glass solution in a three-necked flask, place it in a water bath at a constant temperature of 85°C, start to add 1mol / L sulfuric acid solution at 85°C dropwise with a dropping funnel, and add it at a rate of about 4-5mL / min, Stir vigorously, and measure the change of pH value of the reaction solution with wide pH value test paper. When the pH value reaches 8-9, stop adding dilute sulfuric acid dropwise, stir and age for about 2 hours, and the aging temperature is 85°C;

[0023] (2) Filtrate the resulting sol while it is hot, and repeatedly wash it several times with deionized water, and wash it with 5% BaCl 2 The solution identifies whether there are sulfate ions in the washed water, and after washing, filter to obtain orthosilicate gel;

[0024] (3) Stir the orthosilicic acid gel after filtering and washing with an appropriate amount of n-butanol, then transfer the mixture to a 500mL three-necked flask, add 5% stearic acid, heat and carry out azeo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap