Microbe limit filter

A microbial limit and filter technology, applied in enzymology/microbiology devices, biochemical instruments, methods of supporting/immobilizing microorganisms, etc., can solve problems such as inability to take out, pollute filter membranes, and inaccurate microbial detection, and achieve membrane removal Easy, avoid microbial contamination, ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

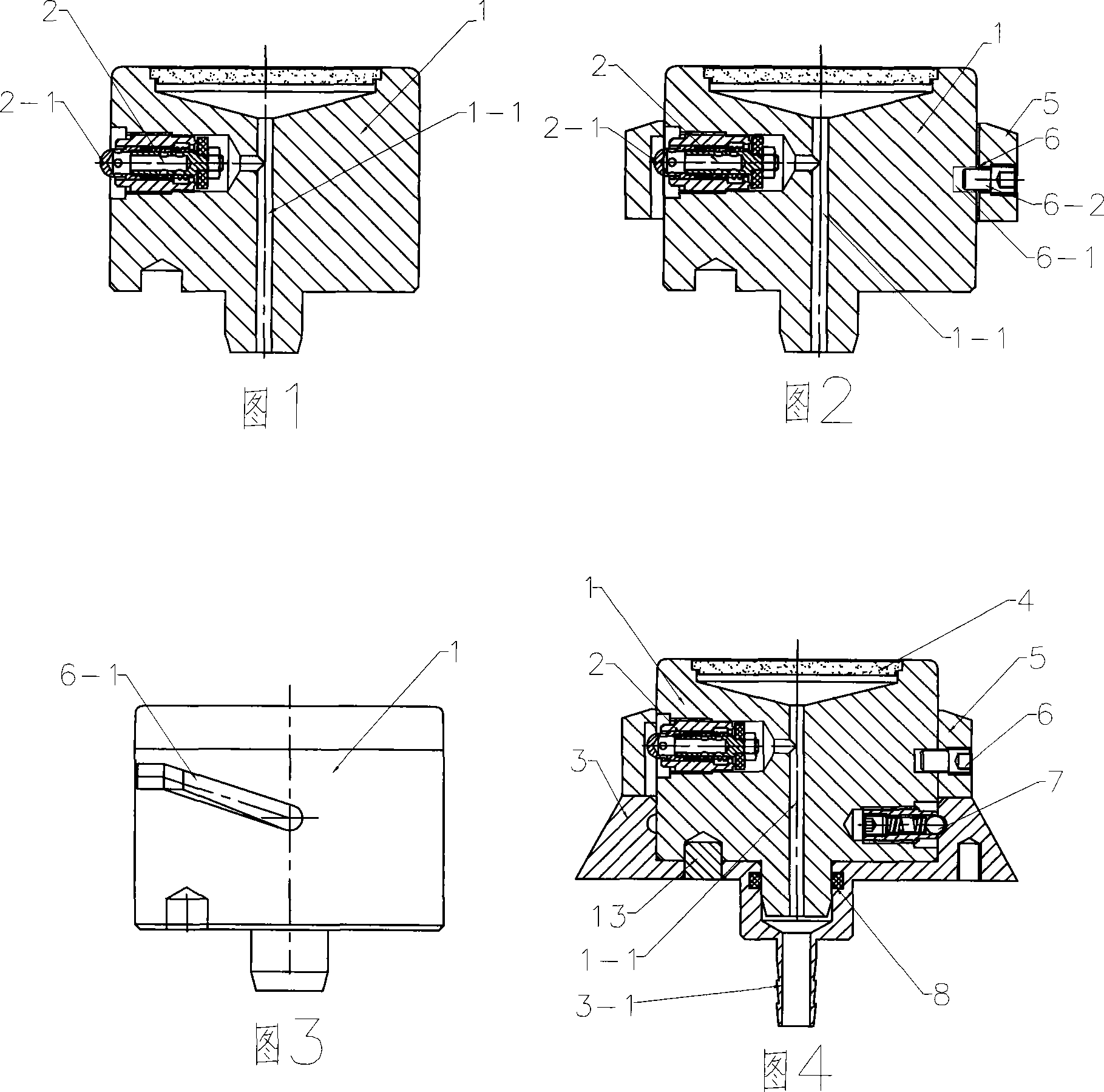

[0013] As shown in Figure 1, the microbial limit filter described in this embodiment includes a filter head 1, on which an air release valve 2 is provided, and the air release switch 2-1 of the air release valve 2 is set in the filter In the side direction of the head 1, the other end of the air release valve 2 communicates with the air suction channel 1-1.

Embodiment 2

[0015] As shown in Figure 2, the microbial limit filter described in this embodiment is provided with a cup taker 5 outside the filter head 1, and a rotating upward structure 6 is provided between the cup taker 5 and the filter head 1 to deflate The vent switch 2-1 of the valve 2 opens and closes by touching and separating with the inner wall of the cup remover 5. The rotating upward structure 6 between the cup taker 5 and the filter head 1 is shown in FIG. 3, and a chute 6-1 is provided on one side of the cylindrical surface between the cup taker 5 and the filter head 1. , The other side is provided with a groove 6-2 at the corresponding chute 6-1. The said groove and tenon 6-2 can be pins, screws, marbles and the like. Here, the chute 6-1 is provided on the cylindrical surface of the filter head 1, and the cup remover 5 is provided with a groove 6-2. The groove 6-2 is a screw and inserted into the chute 6-1.

Embodiment 3

[0017] As shown in Figure 4, the microbial limit filter described in this embodiment is provided with a support 3 under the filter head 1, and a slot-type release positioning structure 7 is provided between the filter head 1 and the support 3, and the support 3 The bottom is provided with a suction nozzle 3-1 communicating with the suction channel 1-1, a positioning hole pin 13 is provided between the bottom of the filter head 1 and the support 3, and a positioning hole pin 13 is provided between the filter head 1 and the support 3 There is a sealing ring 8 and a filter sheet 4 is arranged on the filter surface of the filter head. When in use, the filter head 1 can be easily removed from the support 3 or inserted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com