Heating cooking instrument

A technology of cooker and halogen heater, applied in the field of electric heating cooker

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

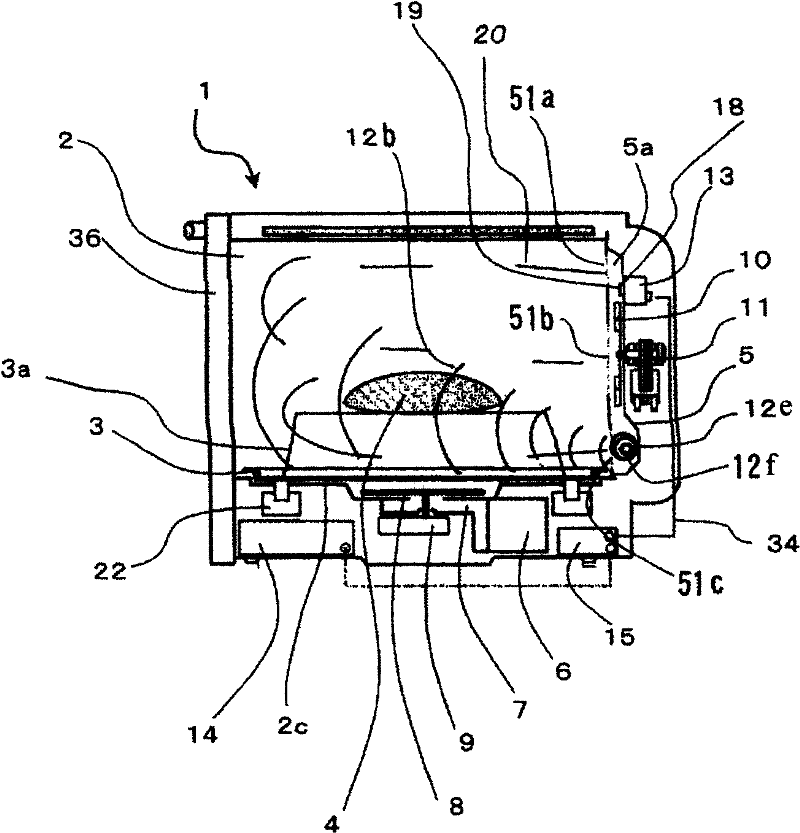

[0083] refer to Figure 1 to Figure 3 A heating cooker as a first embodiment of the present invention will be described.

[0084] figure 1 It is a side sectional view of a state in which an object to be heated 4 is heated by an electric microwave oven as a heating cooker of the present invention.

[0085] figure 2 It is a front view of the interior of the heating chamber seen from the front side with the door of the microwave oven opened.

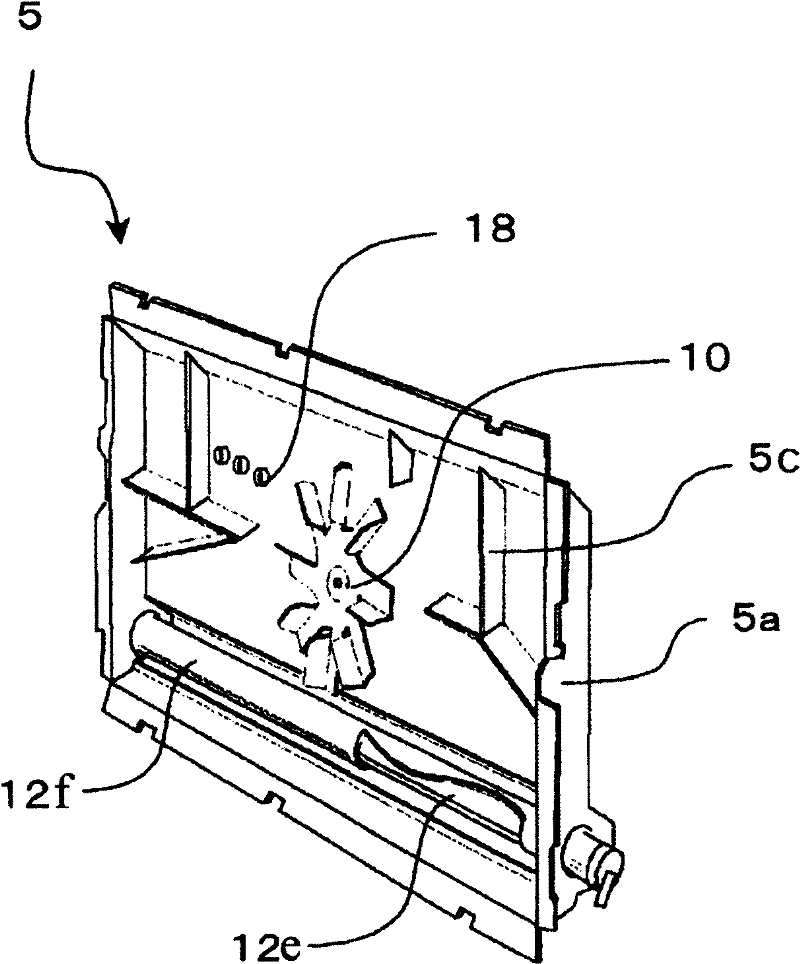

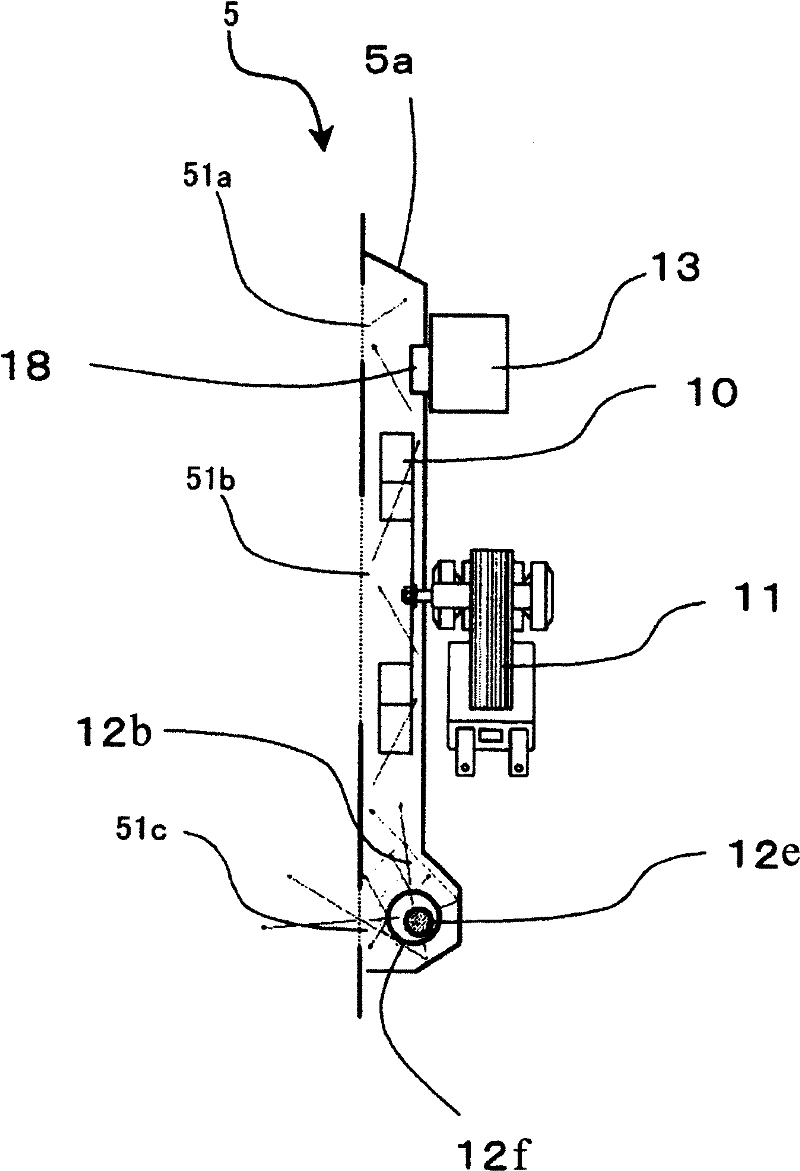

[0086] image 3 It is a perspective view of the hot air unit of the microwave oven.

[0087] The main body 1 of microwave oven is made up of following each part: frame body 35 that constitutes outer contour; Be arranged in frame body 35 and receive the heating chamber 2 of the heated object 4 such as the food that will heat cook; Be arranged on this heating chamber 2 The worktable 3 below and placing the object to be heated 4; the hot air unit 5 that circulates high-temperature air in the heating chamber 2; the magnetron 6 that gener...

Embodiment 2

[0140] refer to Image 6 as well as Figure 7 A heating cooker according to a second embodiment of the present invention will be described.

[0141] Image 6 is a side sectional view of the microwave oven according to the present embodiment.

[0142] This embodiment is characterized in that a halogen heater 12h that radiates a near-infrared wavelength of 0.8 to 2.0 μm at the center is provided as illumination that also functions as an illumination means and a heating means.

[0143] Figure 7 is a graph showing the relationship between the wavelength and the irradiance of the halogen heater 12h according to the present embodiment.

[0144] Here, the irradiance is a parameter indicating the light intensity of a specific wavelength included in the radiated light, and is represented by energy per unit area.

[0145] That is, in the halogen heater 12h according to the present embodiment, as Figure 7 As shown, the illuminance has a peak in the near-infrared region with a wav...

Embodiment 3

[0163] refer to Figure 8 A third embodiment according to the present invention will be described.

[0164] Figure 8 It is a heating cooker that is equipped with a steam generating mechanism 13 on the back upper side of the hot air unit 5 and can perform heating cooking in which steam is supplied to the heating chamber 2 .

[0165] According to this embodiment, not only the saturated water vapor generated by the steam generating mechanism 13 is directly supplied to the heating chamber 2, but also the saturated water vapor particles generated by the steam generating mechanism 13 can be crushed and refined by the blower mechanism 10, and then heated with halogen. The device 12h is further overheated so that superheated steam of 100 to 300° C. can be generated in the hot air unit 5 and supplied to the heating chamber 2 .

[0166] Thereby, compared with the case where heating cooking is performed using only the hot air supplied from the upper heater 38 and the hot air unit 5 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com