Heat insulating pearlite material for outer wall and its prepn process

A technology for thermal insulation materials and external wall insulation, which is applied in the field of thermal insulation materials for building exterior walls and its preparation, and can solve problems such as potential safety hazards, unbearable wind pressure resistance, and inability to firmly combine polystyrene boards with cement-polyphenylene mortar.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

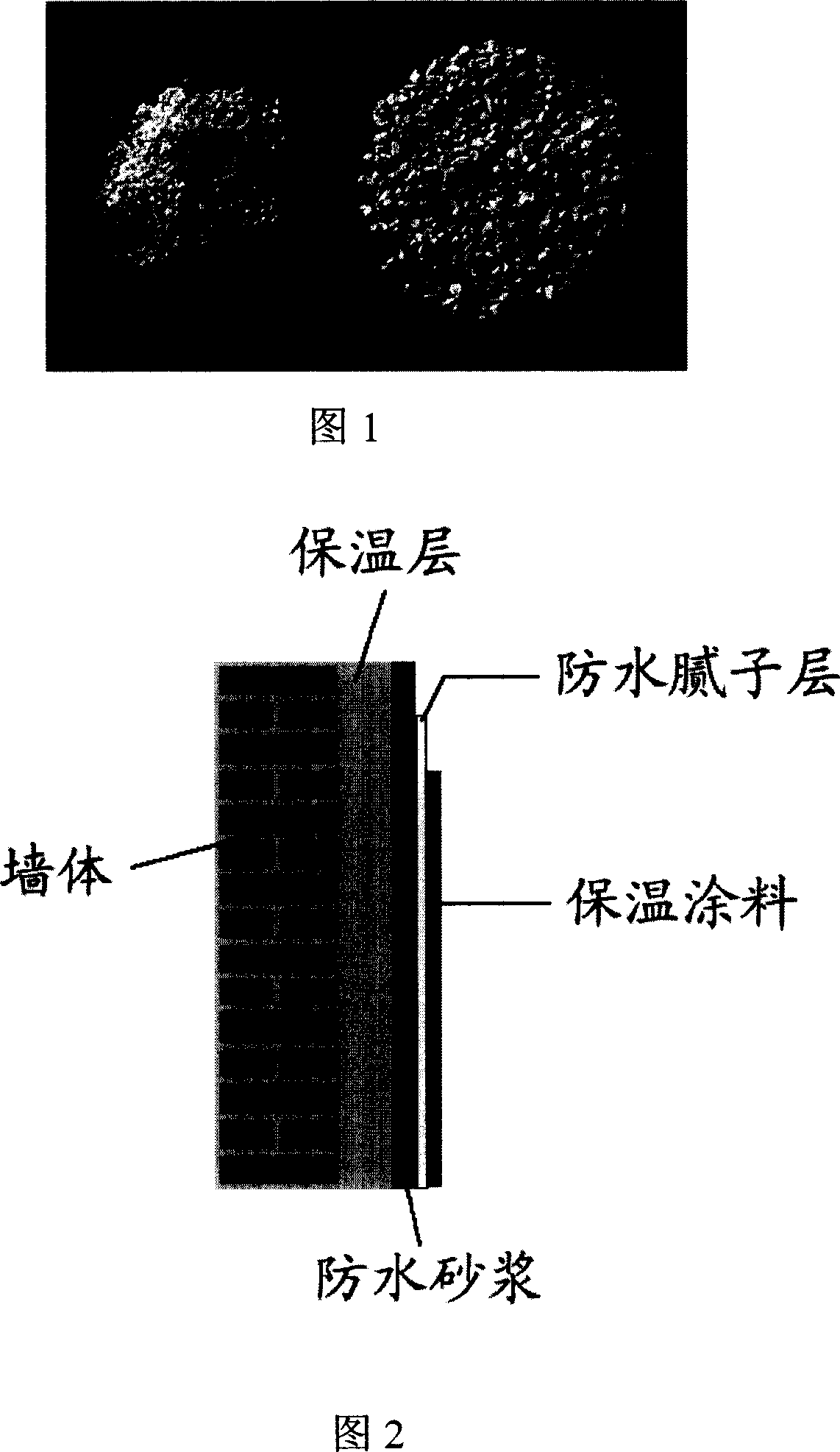

Image

Examples

Embodiment 1

[0029] Preparation of modified expanded perlite:

[0030] Each component was weighed according to the following weight (unit: kg): acidified magnesium insulation material additive 50 (purchased from Shanghai Yuchen Technology Co., Ltd. and the trade name is "Shuangheng" brand insulation material), modified expanded perlite 300 ; Mix the above-mentioned components evenly and stir to obtain.

[0031] When carrying out building thermal insulation construction, the prepared thermal insulation material and 455kg waterproof liquid (the waterproof liquid is prepared by water and waterproof agent according to the weight ratio of 16:1, wherein the waterproof agent is purchased from Chengdu Xinglong Chemical Co., Ltd., trade name After mixing "KL-205 Kele" high-efficiency waterproofing agent), stir for 16 minutes, and then carry out building wall insulation construction according to conventional methods.

Embodiment 2

[0033] Preparation of modified expanded perlite: same as Example 1.

[0034] Each component was weighed according to the following weight (unit: kg): acidified magnesium insulation material additive 15 (purchased from Shanghai Yuchen Technology Co., Ltd. and the trade name is "Shuangheng" brand insulation material), modified expanded perlite 50 ; Mix the above-mentioned components evenly and stir to obtain.

[0035] When carrying out building thermal insulation construction, the prepared thermal insulation material and 97.5kg waterproof liquid (the waterproof liquid is prepared by water and waterproof agent according to the weight ratio of 16:1, wherein the waterproof agent is purchased from Chengdu Xinglong Chemical Co., Ltd., commodity The name is "KL-205 Kele" high-efficiency waterproofing agent) after mixing, stir for 10 minutes, and then carry out building wall insulation construction according to conventional methods.

Embodiment 3

[0037] Preparation of modified expanded perlite: same as Example 1.

[0038] Each component was weighed according to the following weight (unit: kg): acidified magnesium insulation material additive 10 (purchased from Shanghai Yuchen Technology Co., Ltd. and the trade name is "Shuangheng" brand insulation material), modified expanded perlite 40 ; Mix the above-mentioned components evenly and stir to obtain.

[0039] When carrying out building thermal insulation construction, the prepared thermal insulation material and 70kg waterproof liquid (the waterproof liquid is prepared by water and waterproof agent according to the weight ratio of 16:1, wherein the waterproof agent is purchased from Chengdu Xinglong Chemical Co., Ltd., trade name After mixing "KL-205 Kele" high-efficiency waterproofing agent), stir for 15 minutes, and then carry out building wall insulation construction according to conventional methods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com