Fuel injector for internal combustion engine and corresponding method of manufacture

一种燃料喷射器、内燃机的技术,应用在燃料喷射装置、特殊燃料喷射装置、机器/发动机等方向,能够解决减小能力、降低热交换能力等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

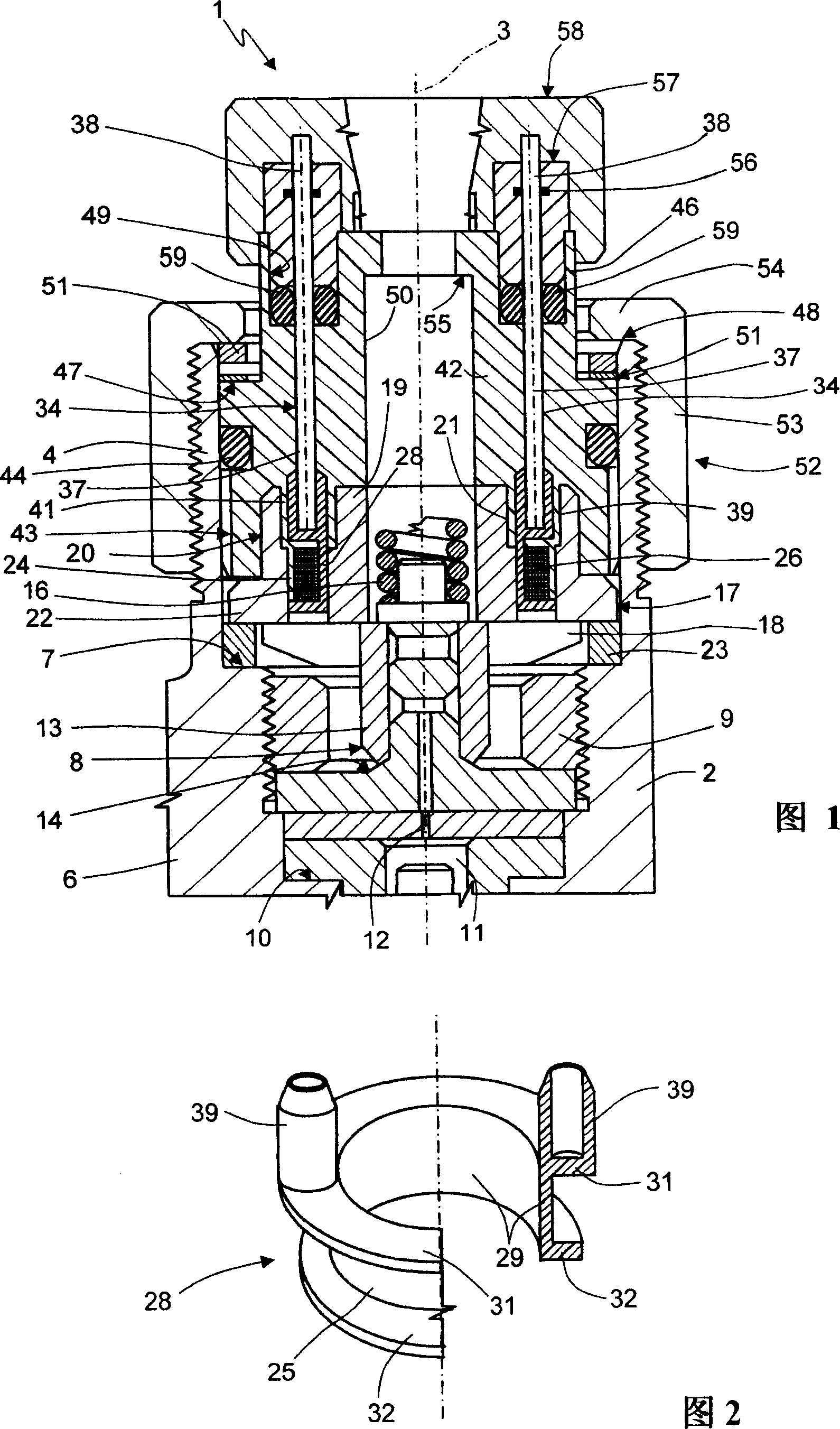

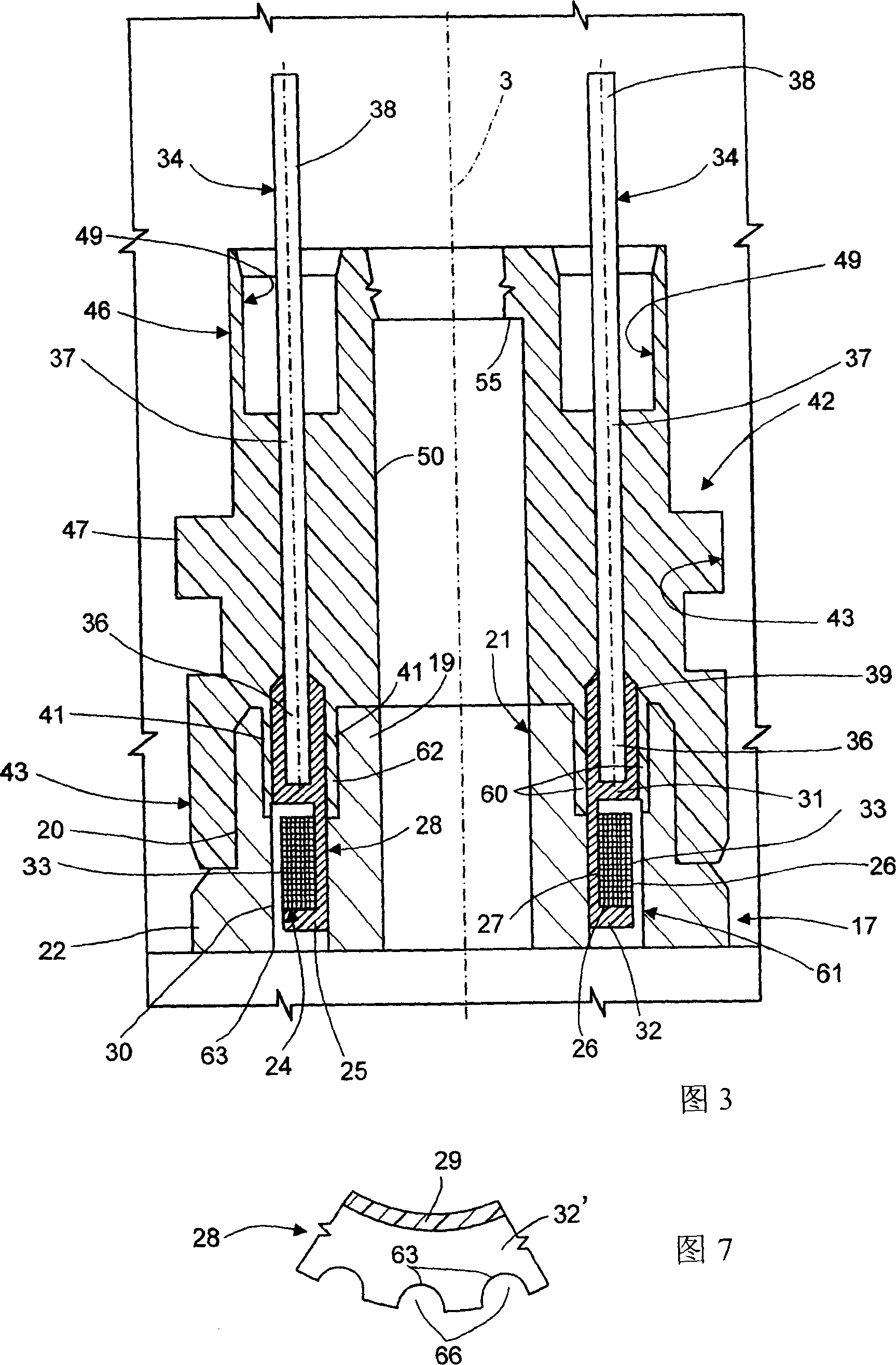

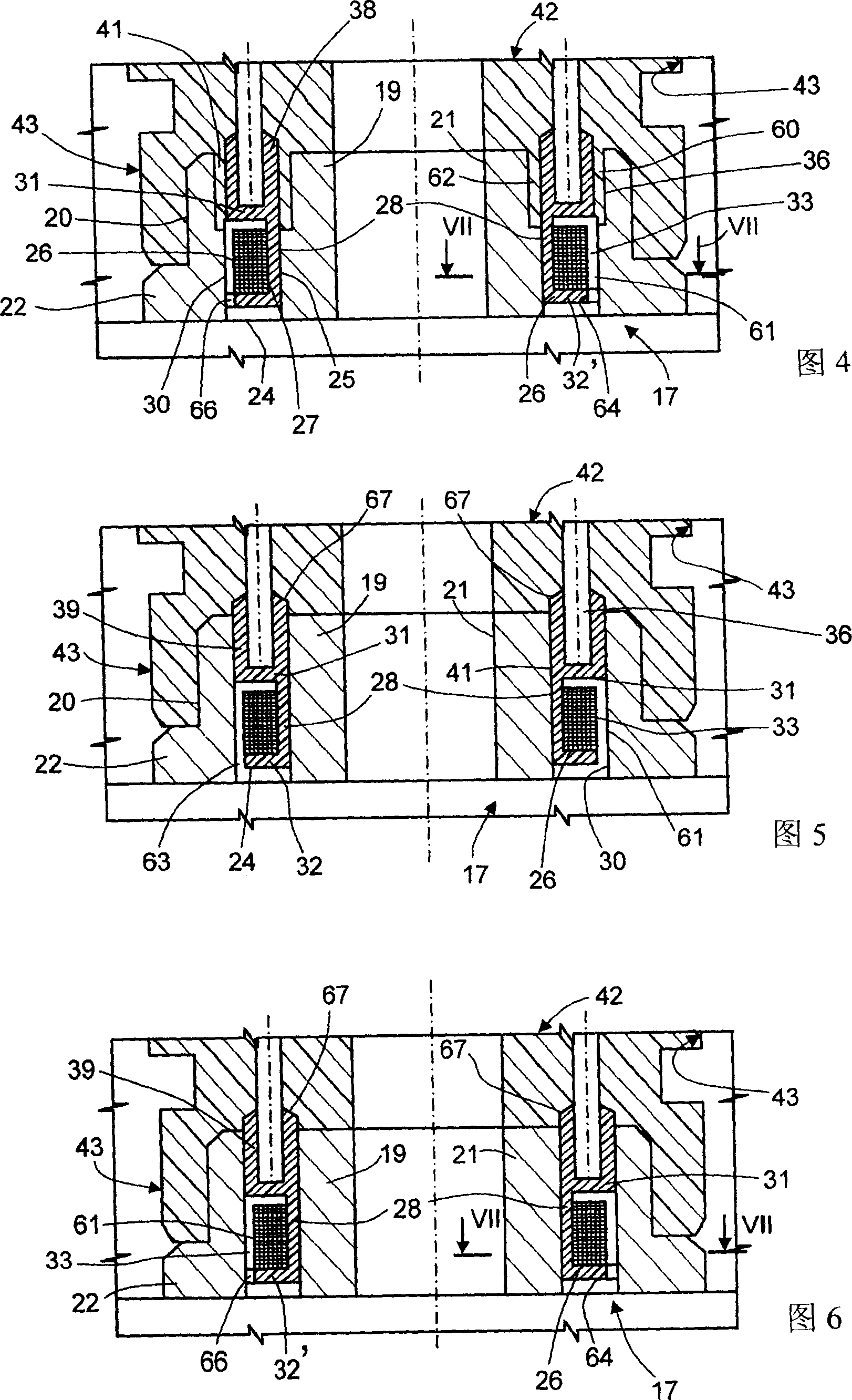

[0025] Referring to FIG. 1 , reference numeral 1 is used to denote generally a fuel injector (injector) for an internal combustion engine comprising a housing formed by a tubular hollow body 2 having an axis 3 . The hollow body 2 starts at the upper free end and contains two tubular extensions 4 and 6 which are radiused by an inner shoulder 7 perpendicular to the axis 3 and constricted in inner diameter. The tubular extension 6 is equipped with a metering valve 8 for injection, and the metering valve 8 is blocked on the boss 10 of the tubular extension 6 through a nut 9 .

[0026] The metering valve 8 comprises a control chamber 11 with a graduated tube 12 for discharging fuel from the control chamber 11 under pressure. The graduated tube 12 is normally closed by a shutter / valve 13 which is pressed against an opposing surface 14 by a coil spring 16 which will be described in more detail below. The scale tube 12 opens under the opposite action of a brake consisting of an elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com