Condensation water recovery system

A technology for recovering system and condensed water, applied in supplementary water supply, preheating, steam generation, etc., which can solve the problems of energy waste and achieve energy saving, quantifiable control, and stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

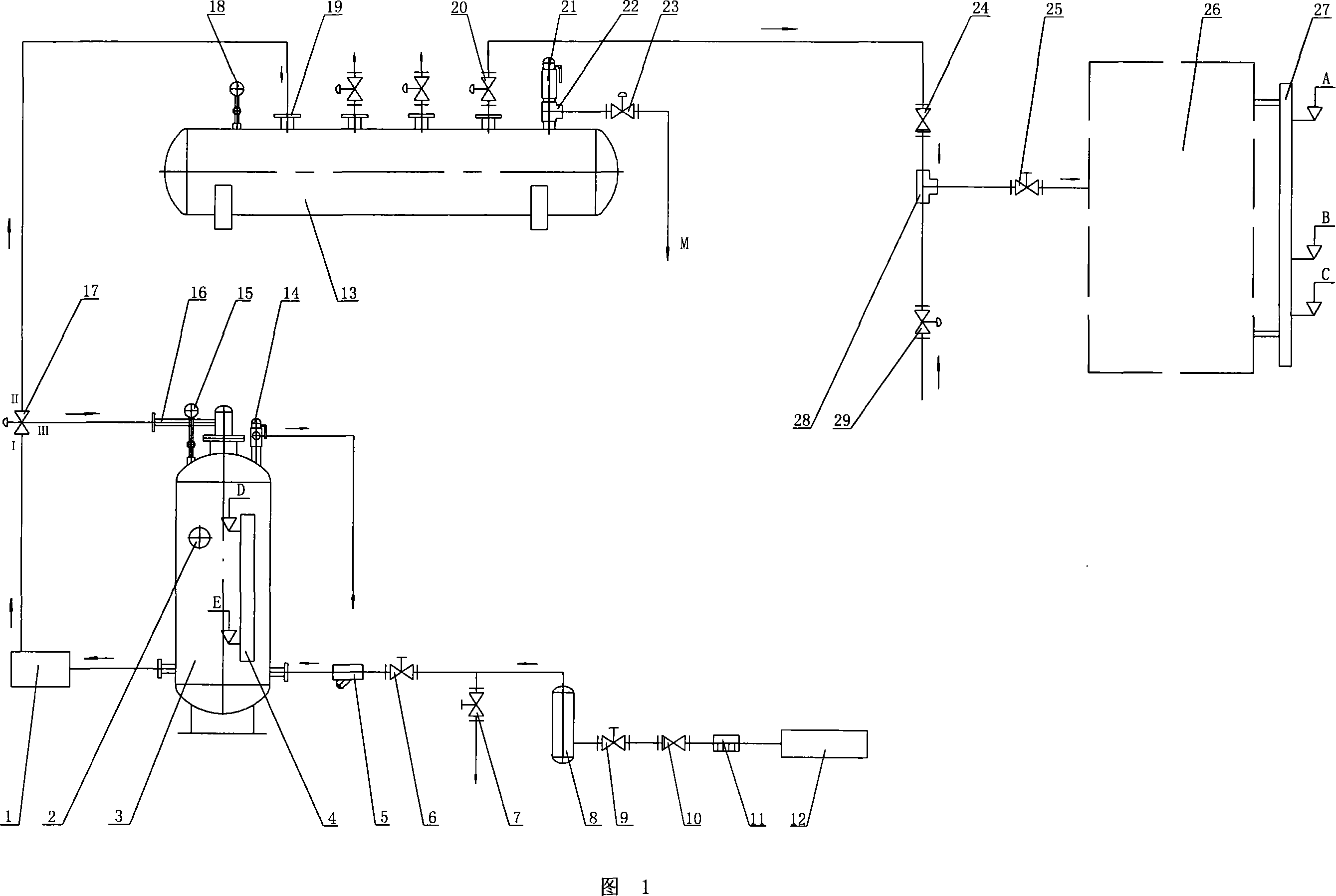

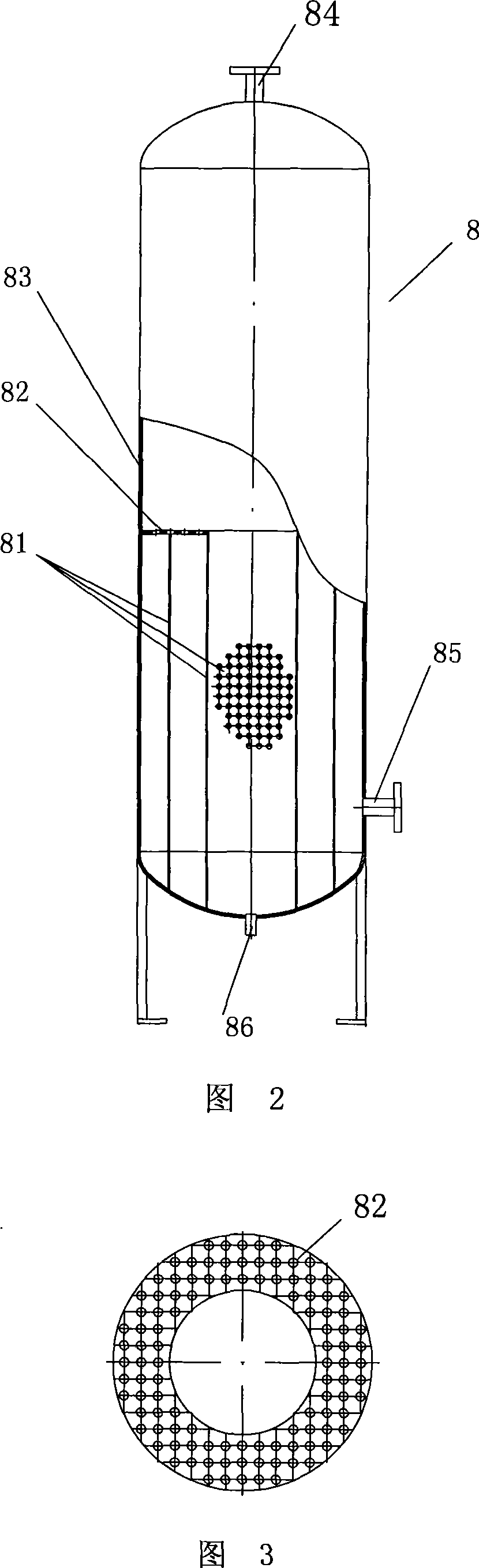

[0012] Referring to Fig. 1, the present invention is provided with multi-stage pump 1, thermometer 2, water storage tank 3, liquid level gauge 4, filter 5, first manual valve 9, third manual valve 7, second manual valve 6, fourth Manual valve 25, buffer 8, first one-way valve 10, second one-way valve 24, steam trap 11, water diversion cylinder 13, safety valves 14 and 21, pressure gauges 15 and 18, return pipe 16, pneumatic tee Valve 17, water inlet flange 19, first pneumatic valve 20, second pneumatic valve 29, third pneumatic valve 23, first three-way pipe 28, second three-way pipe 22 and other corresponding connecting pipes.

[0013] The condensed water outlet of the steam-using equipment 12 is connected to the water inlet of the buffer 8 through the steam trap 11, the first one-way valve 10, and the first manual valve 9. The manual valve 6 and the filter 5 are connected to the lower inlet of the water storage tank 3, and the lower outlet of the water storage tank 3 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com