Solenoid valve for controlling the flow of brake oil

A technology of solenoid valve and brake fluid, applied in the field of solenoid valve, can solve the problem of small turning angle of the vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

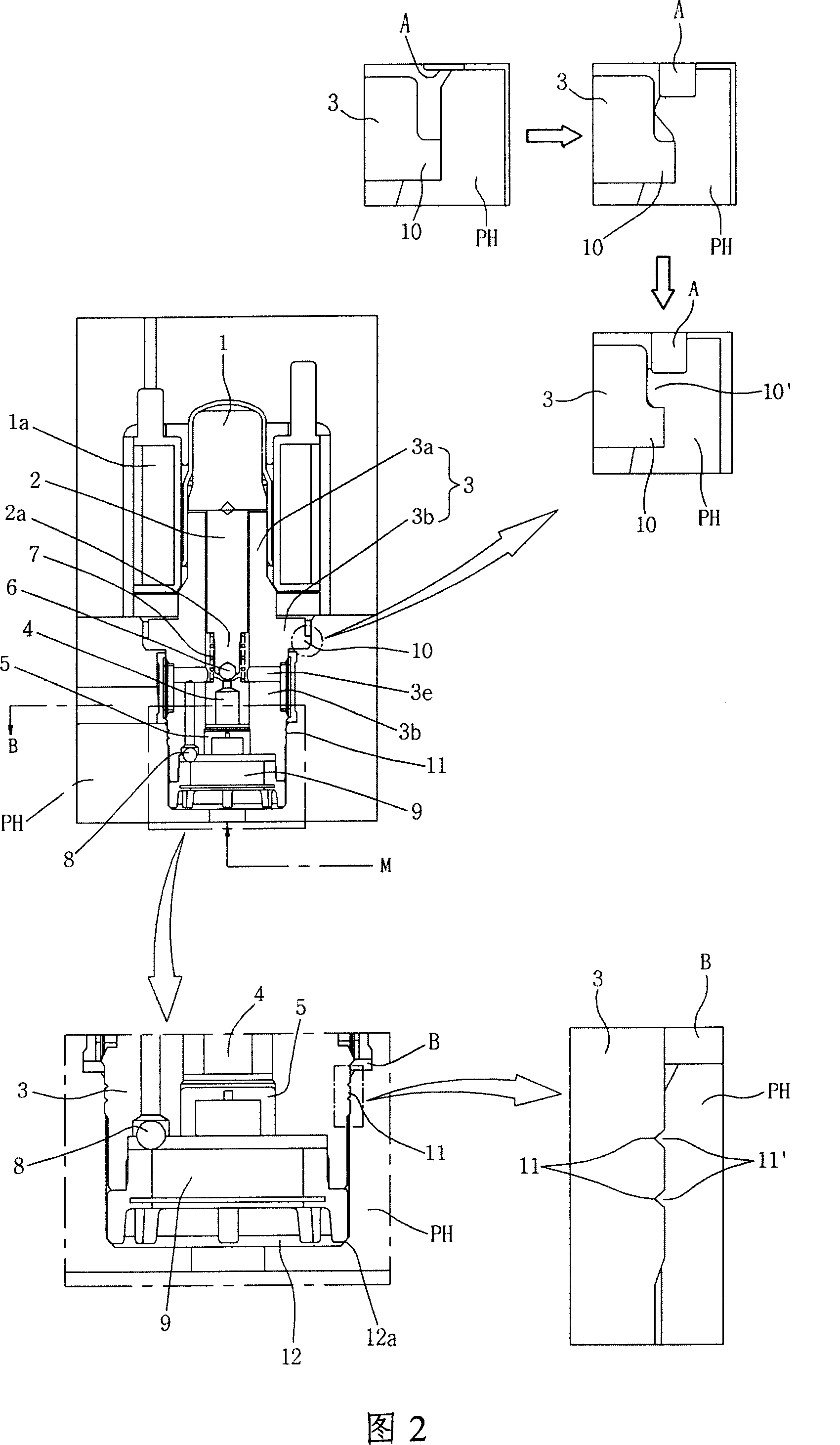

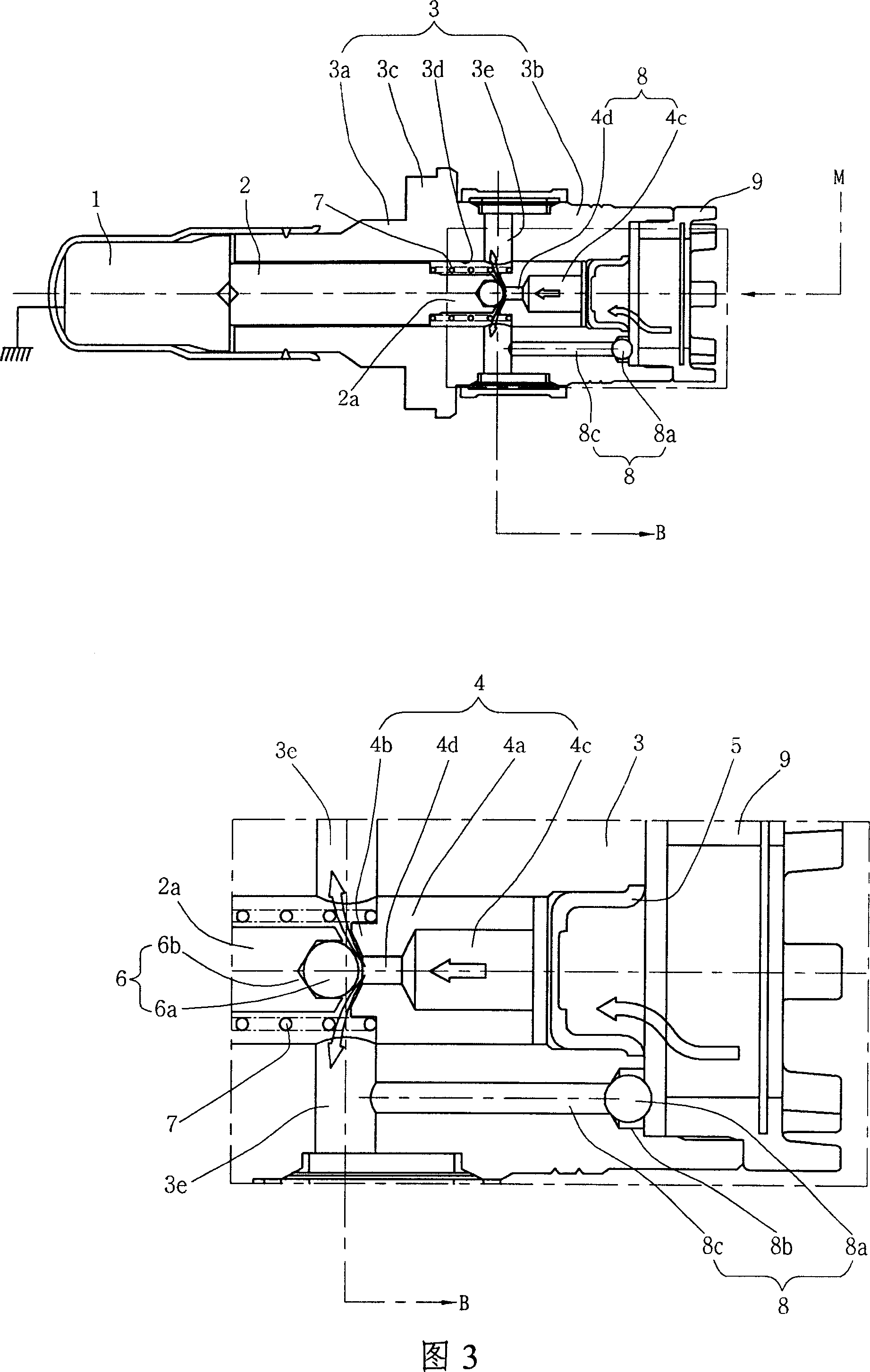

[0022] The invention is illustrated in detail in the accompanying drawings with reference to a preferred embodiment of the invention. The same reference numerals in the drawings and the description shall denote the same component.

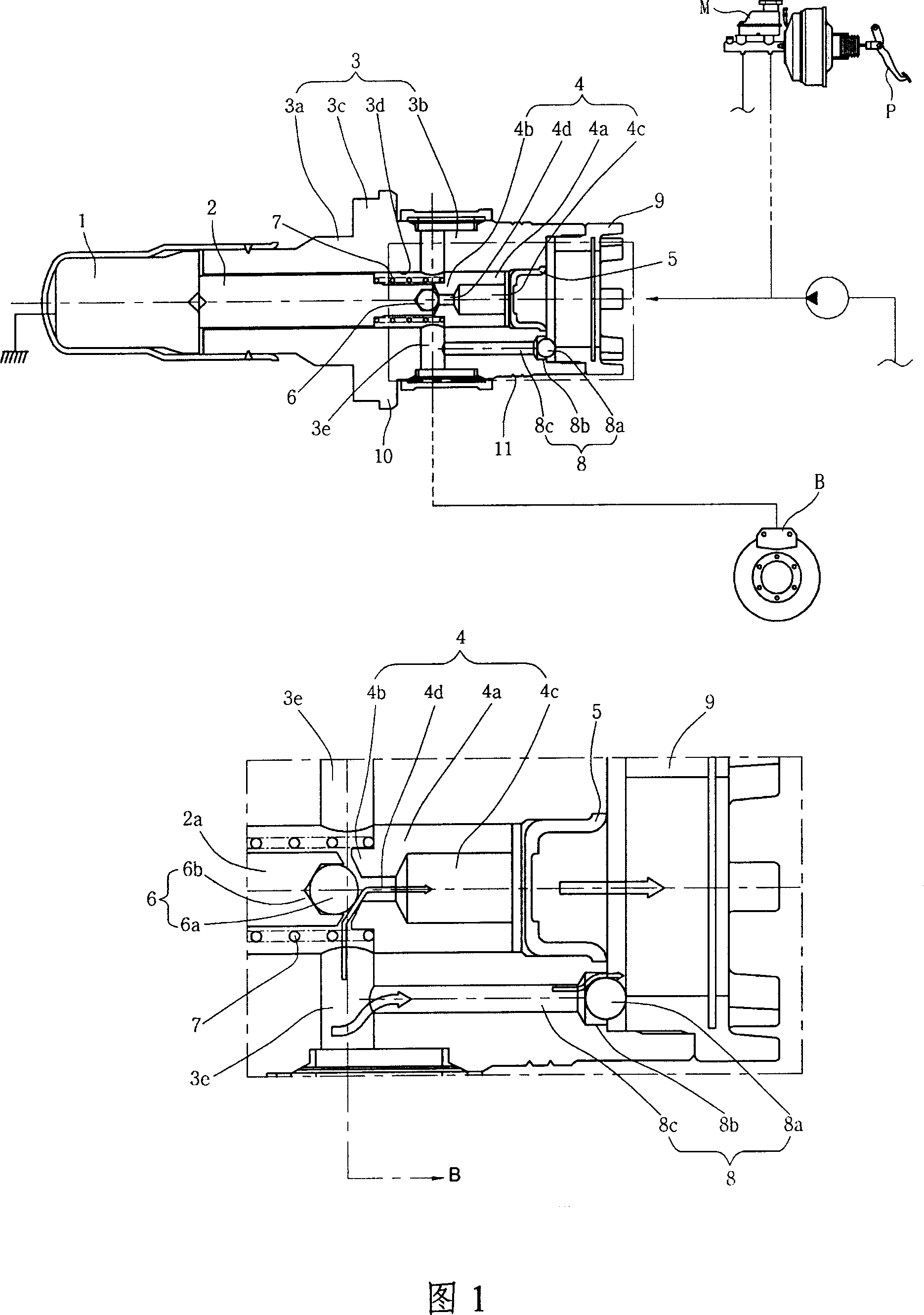

[0023] FIG. 1 is a structural sectional view of a solenoid valve for controlling the flow of brake fluid according to an embodiment of the present invention. According to the present invention, the solenoid valve plays a role of providing hydraulic braking force, which is generated by the master cylinder M and transmitted to the braking mechanism B of the wheel through a booster used to increase the stepping force of the brake pedal P. The solenoid valve consists of a plunger 2 actuated by an armature 1 wound with a coil 1a that provides the power to depress the brake pedal in response to a control signal from the control unit, switching the contact ends of the flow path 2a is formed at the end of the plunger 2; a valve body 3, which is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com