Technique for manufacturing packer with fusing mechanism

A manufacturing process and compression adjustment technology, which is applied to the parts of the strapping machine, paper/cardboard containers, containers, etc., and can solve the problems of inability to perform a fastening function, improper placement of metal clips, deformation of metal clips, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

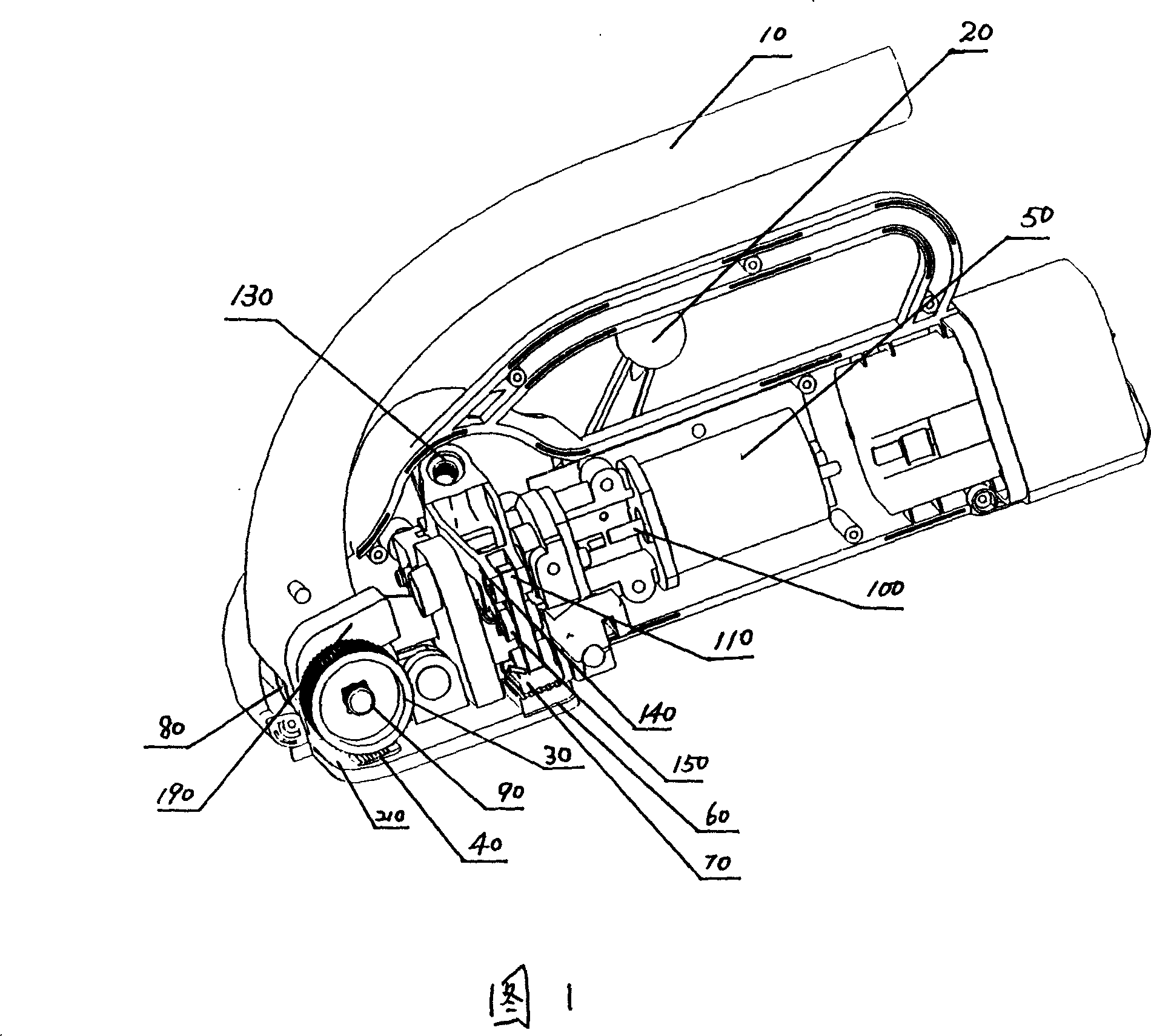

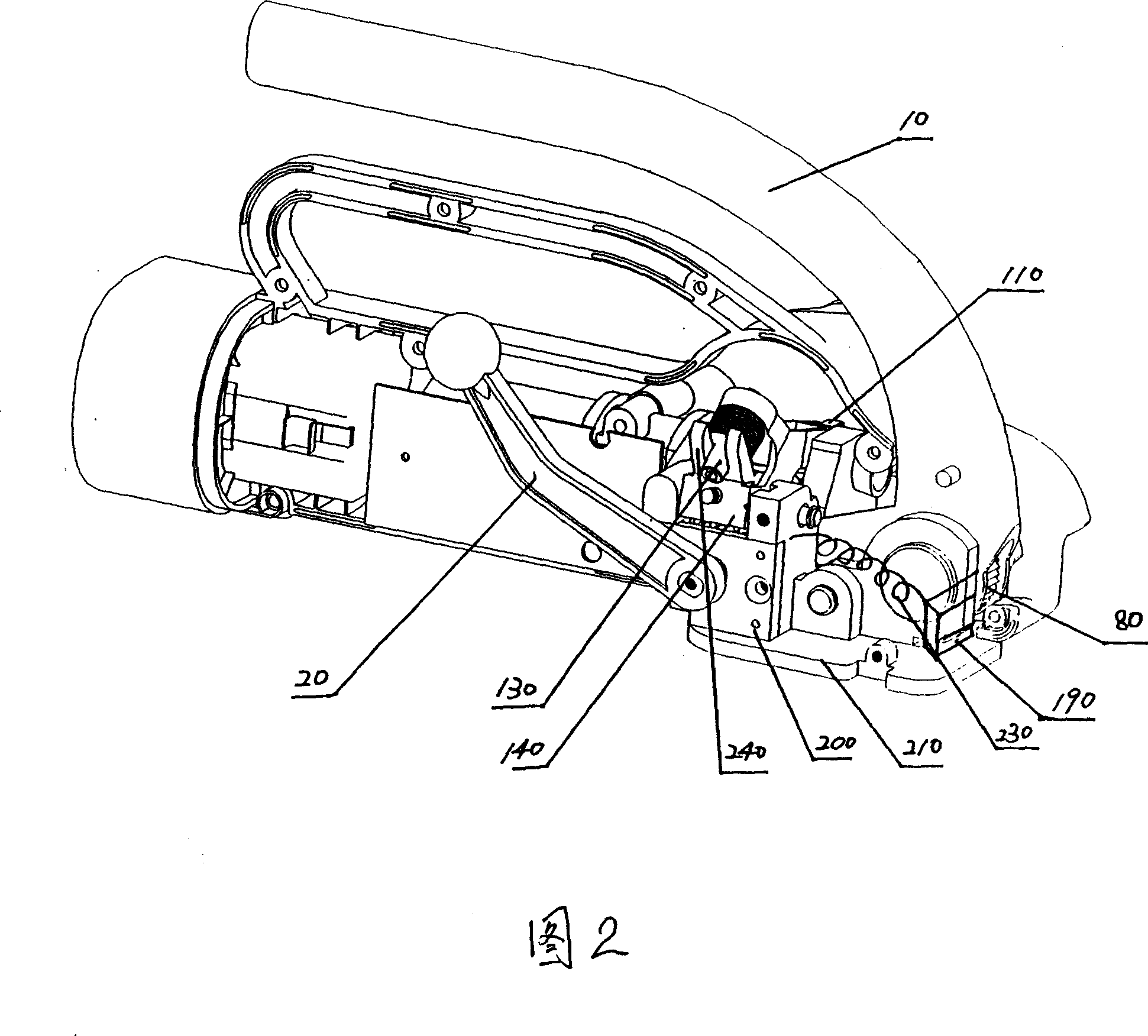

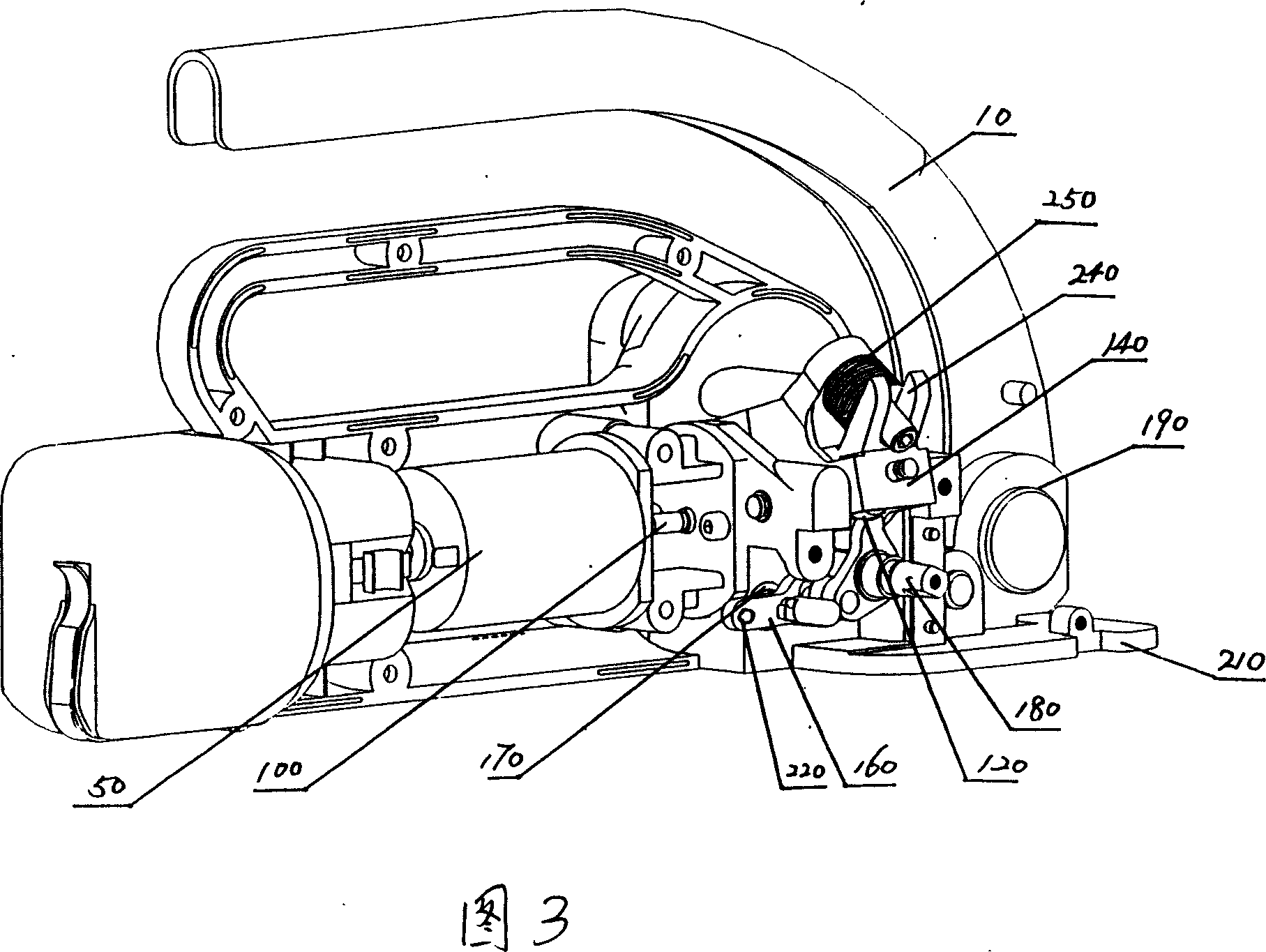

[0010] A manufacturing process of a baler with a fusion mechanism, which mainly includes the following steps: A. A pressing arm is provided in the wall panel, a pressing adjustment part is provided on the pressing arm, and a pressing roller is provided on the pressing adjustment part through a pin , the compression adjustment screw passes through the opening of the compression adjustment part and then is screwed into the screw hole of the compression arm; B. The compression adjustment screw is provided with an arched spring, and the compression arm is provided with a compression belt connecting rod through a pin, The connecting rod of the pressure belt is provided with a swing arm and a swing tooth plate through a pin, and a fixed tooth plate is provided on the bottom plate at the corresponding position under the swing tooth plate. C. The swing arm is connected with the eccentric shaft connected with the DC motor, and the compression adjustment connected to the camshaft. Below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com