Measurement of oxidizing stabilization for oil-condition managing

A stable, oxygen flow technology, applied in the field of oil quality sensors, micro heaters and micro heater arrays, oil oxidation stability measurement system, can solve the problems of unsuitable real-time measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

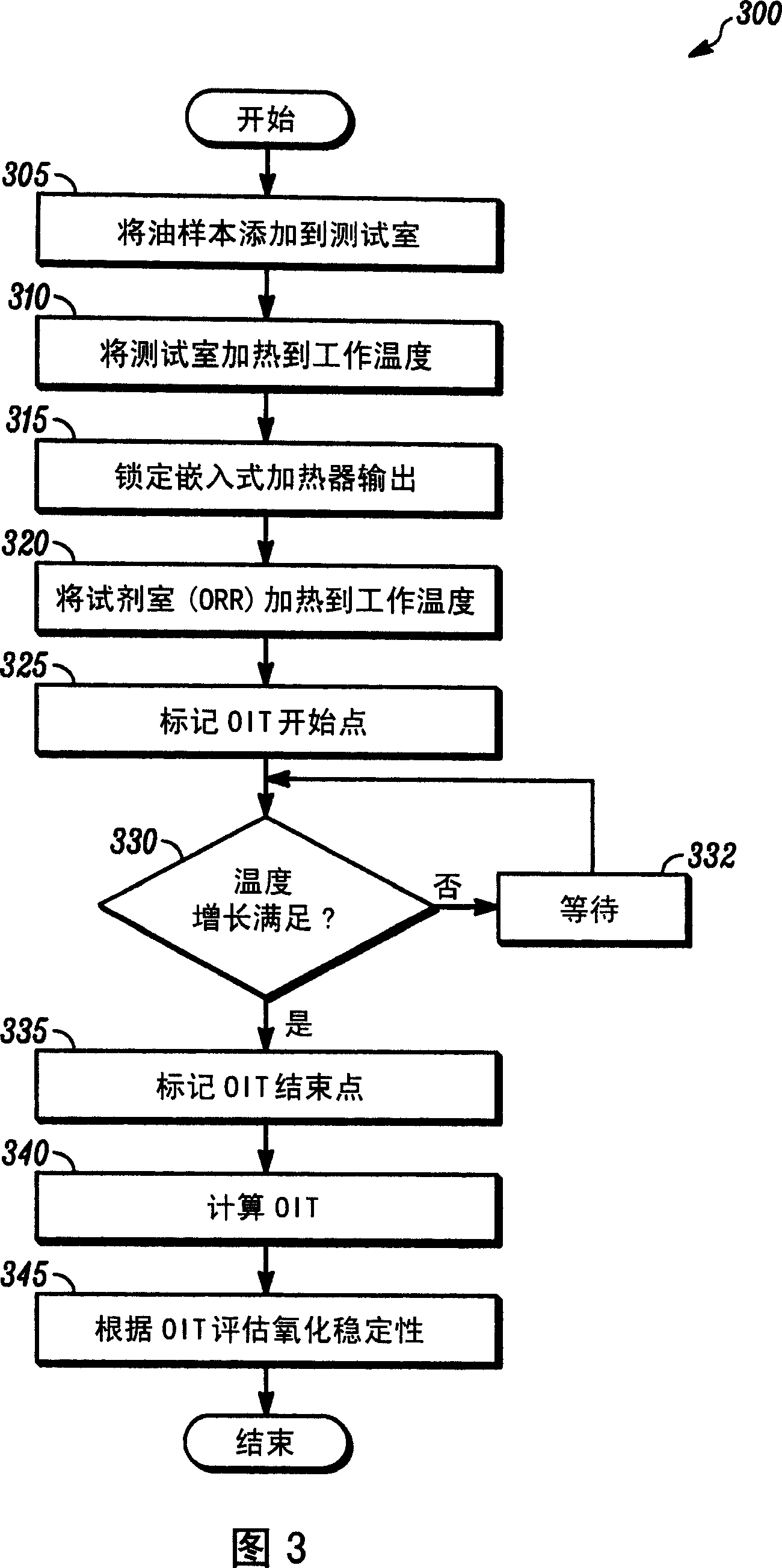

[0027] The specific values and configurations discussed in these non-limiting examples can be varied and cited merely to demonstrate at least one embodiment, and are not intended to limit the scope of the invention.

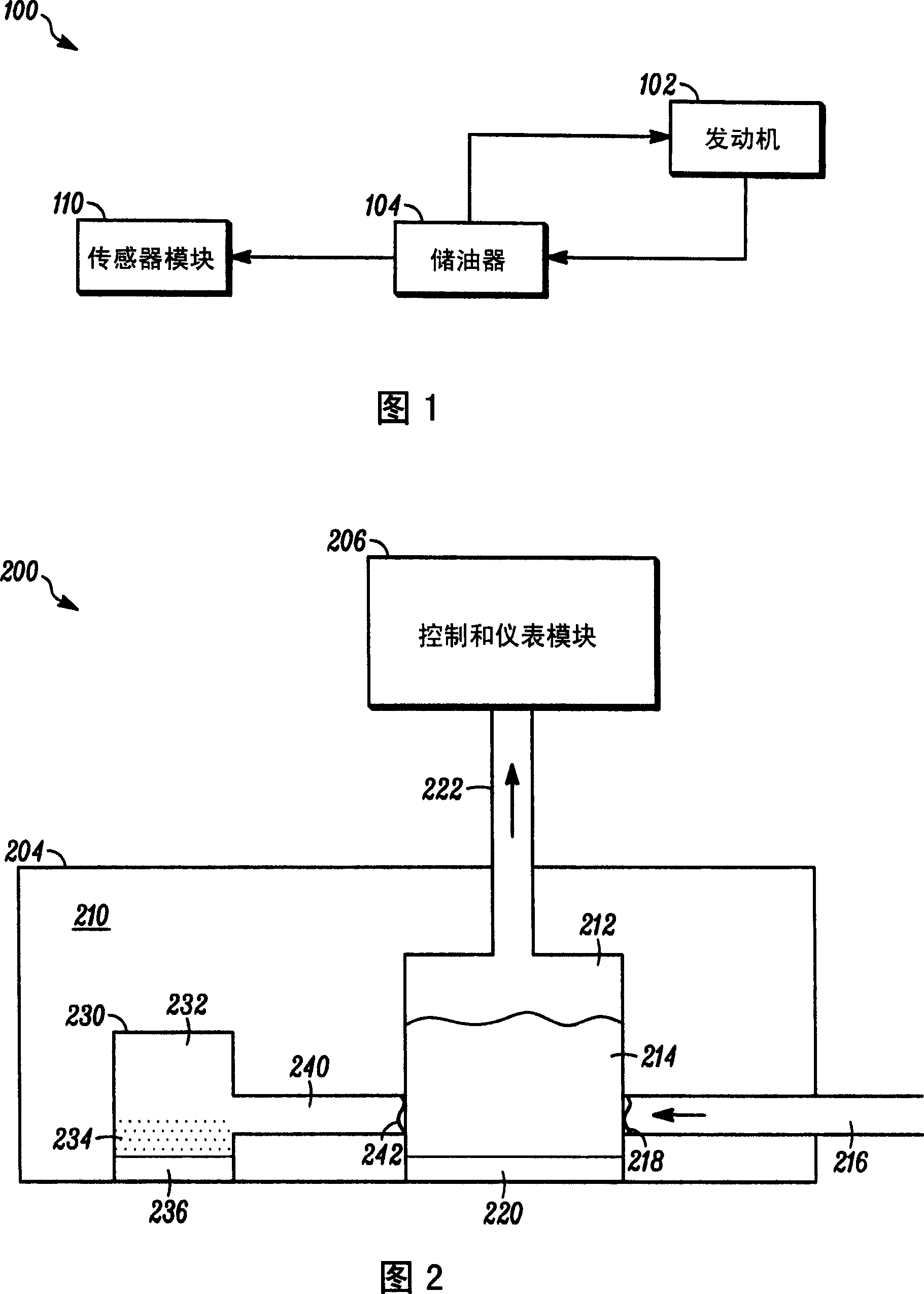

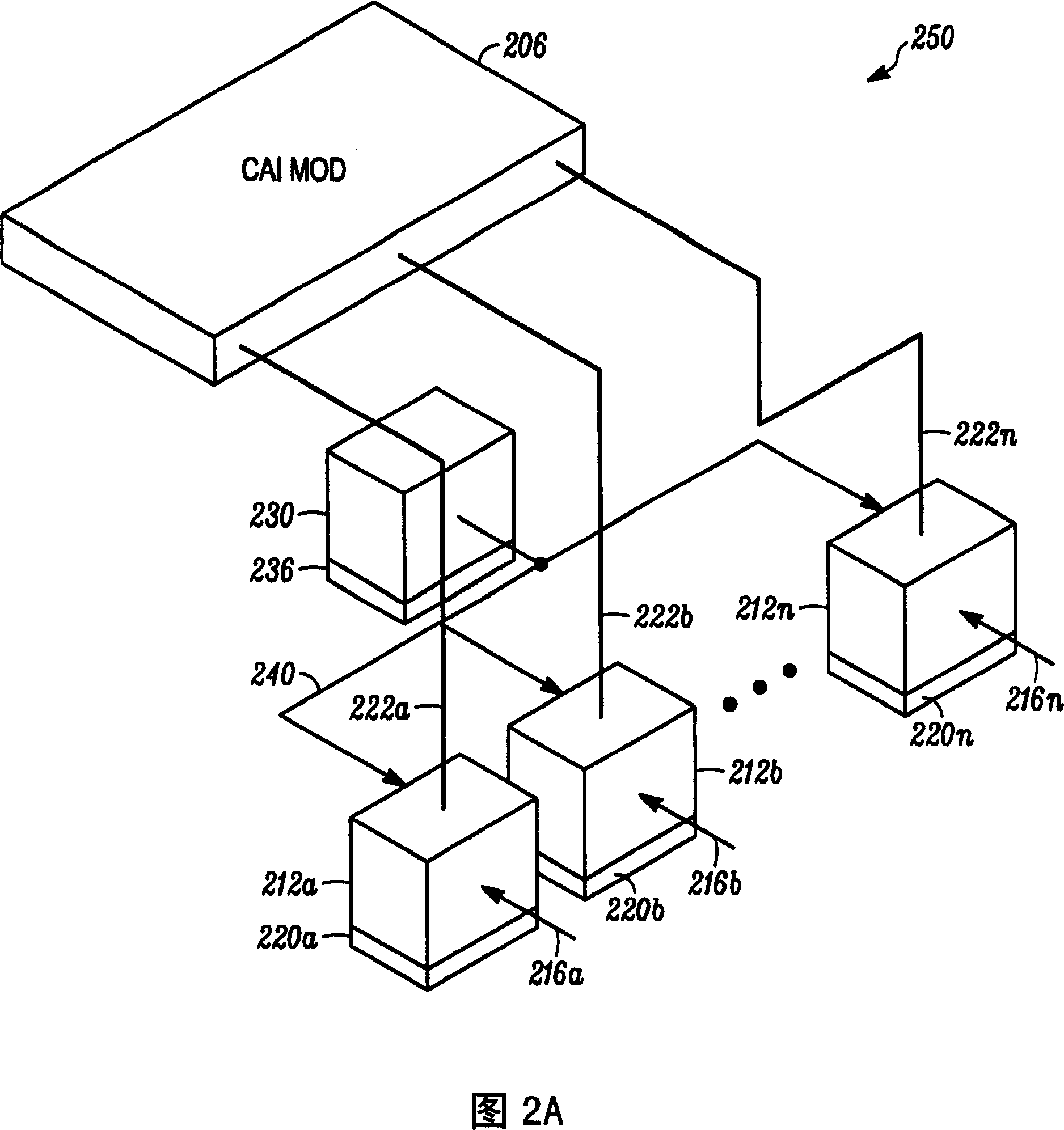

[0028] Figure 1 shows an advanced oil quality management system according to one embodiment of the present invention. In particular, FIG. 1 is a block diagram illustrating a sensing system, generally indicated by reference numeral 100 . As detailed below, the present invention provides a device for quantifying the quality of oil in use, specifically the oil oxidation induction time (OIT), with improved performance over devices currently on the market, which device accordingly provides Improvements in system-wide oil quality and replacement management.

[0029] For ease of illustration, the embodiments disclosed herein are described with reference to electric motor / engine lubricating oil. Those skilled in the art will appreciate that the embodiments disclosed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com