Structure for assembling faceplate

A technology for assembling structures and panels, applied in the installation of support structures, rack/frame structures, instruments, etc., can solve problems such as unfavorable lightweight development of notebook computers, increase in weight of notebook computers, etc., to improve reliability, reduce weight, The effect of simplifying the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

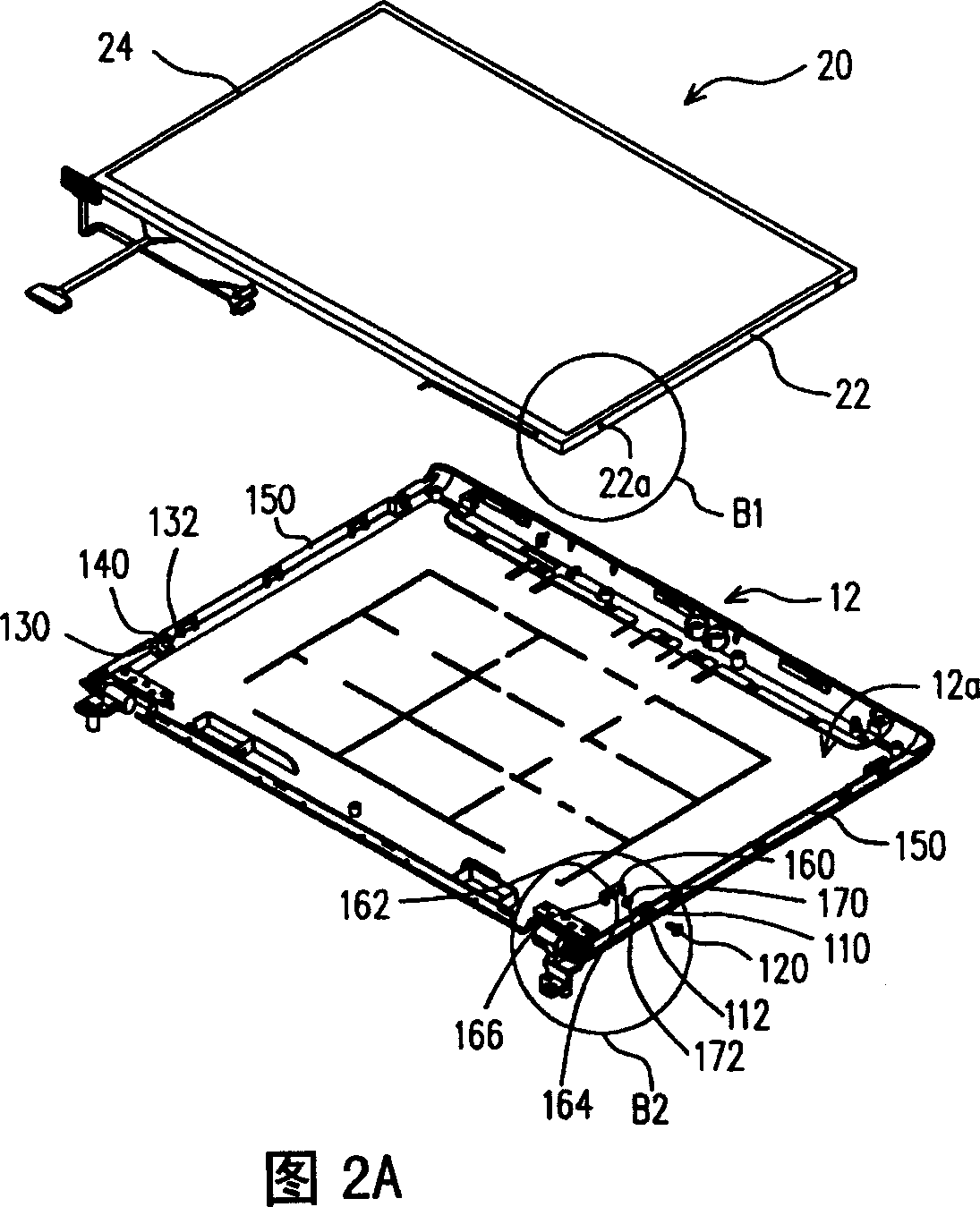

[0033] In order to make the above and other objects, features and advantages of the present invention more comprehensible, an embodiment will be described in detail below together with the accompanying drawings.

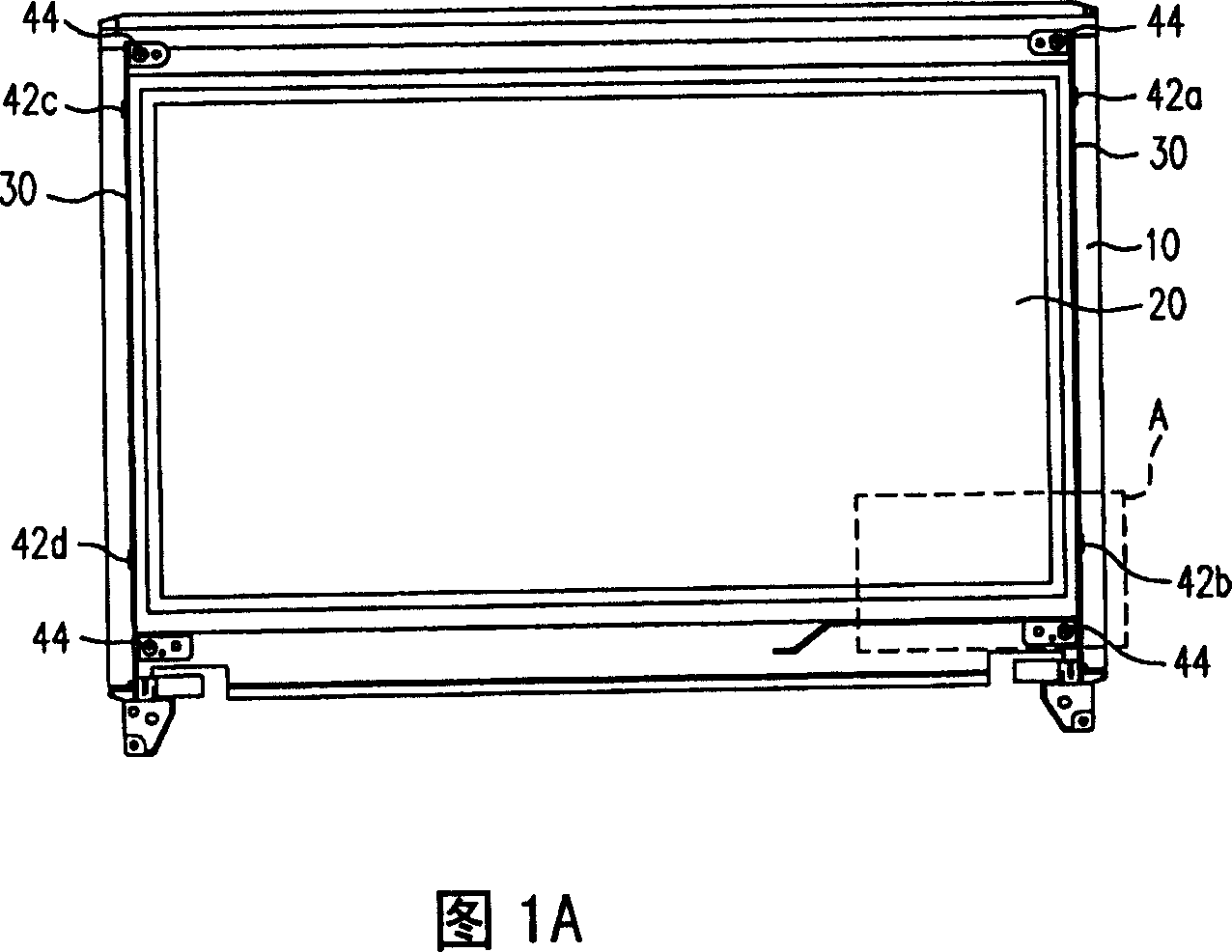

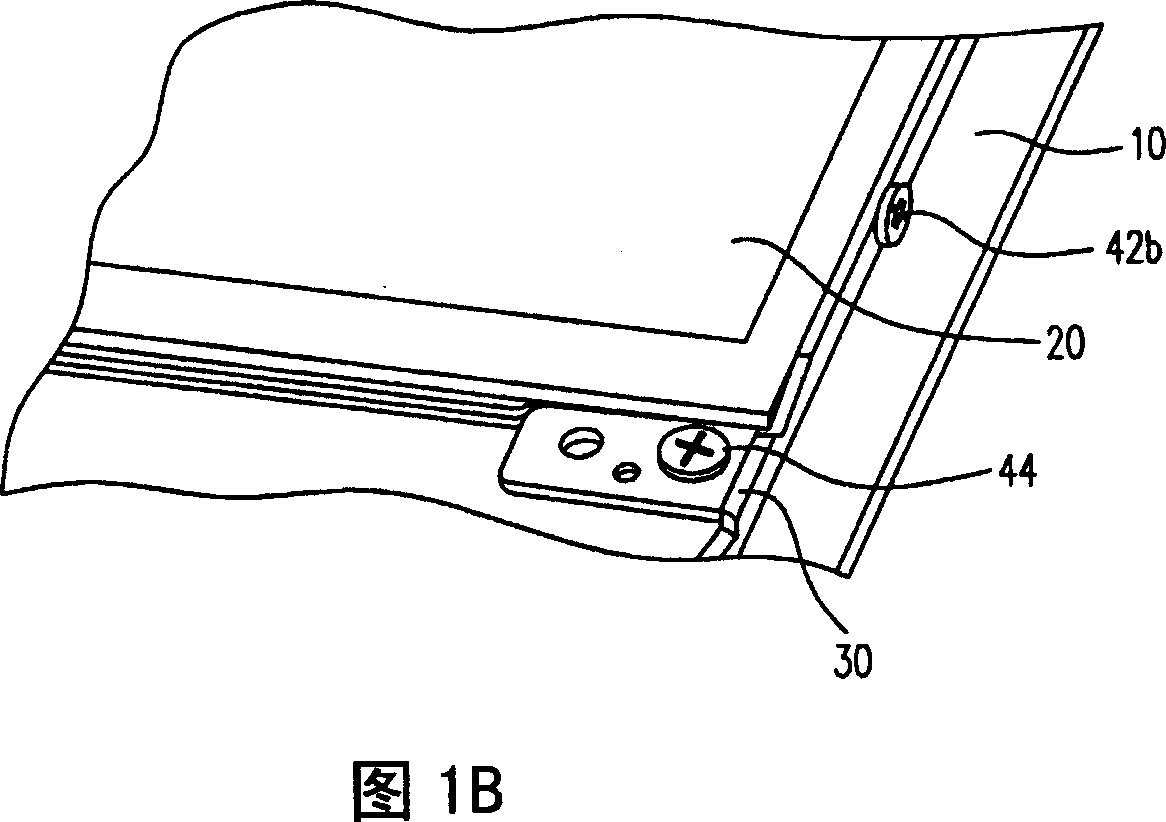

[0034] The panel assembly structure of the present invention can assemble a display panel on the inner surface of a casing of the electronic device. In this embodiment, a notebook computer and a liquid crystal display panel assembled on the panel cover of the notebook computer are taken as examples for illustration. In addition, the panel assembly structure of the present invention can also be applied to other electronic devices with display panels, such as mobile phones, language translators, digital cameras, digital video cameras, personal digital assistants, and the like.

[0035] Figure 2A and Figure 2B are a perspective exploded view and a top view of a panel assembly structure according to an embodiment of the present invention before assembling the panel to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com