Lighting assembly and method of operating a discharge lamp

A technology of a lighting device and an operating method, which is applied to lighting devices, electric light sources, electrical components, etc., can solve the problems of discharge lamp maintenance failure, loss of luminous flux, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

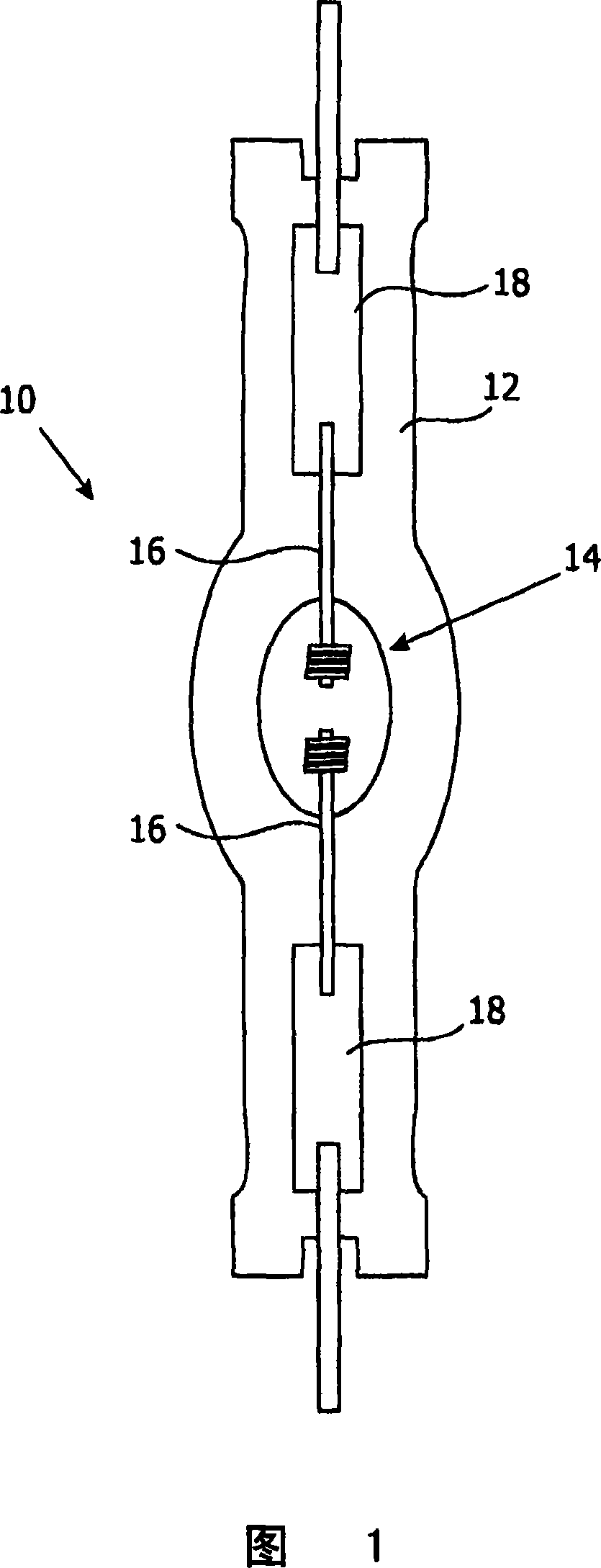

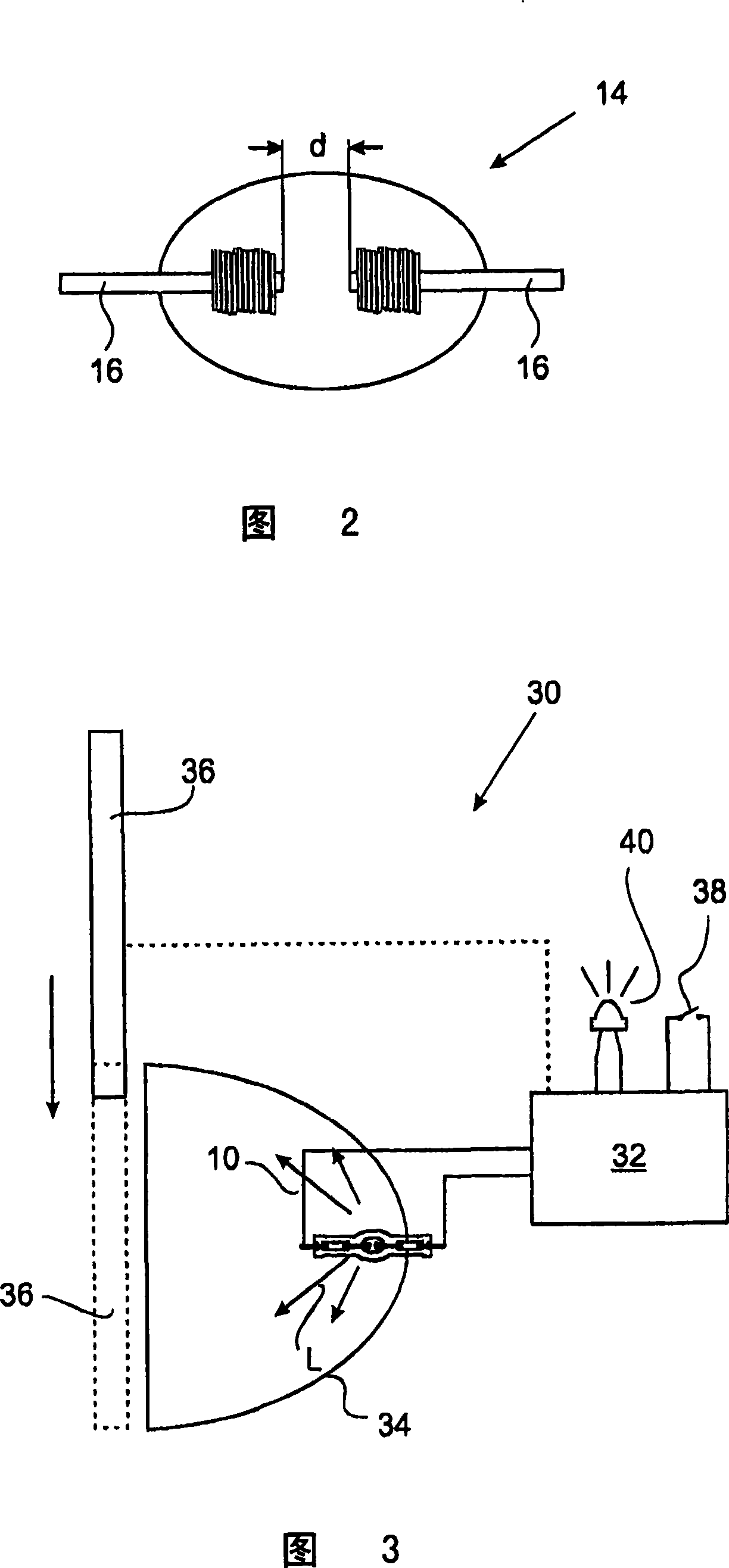

[0031] Figure 1 shows a UHP lamp 10 as an example of a HID lamp. A quartz bulb 12 surrounds a generally rotationally symmetrical discharge vessel 14 . The outer diameter of the bulb is 10.2 mm; the inner diameter is 5 mm. An electrode 16 is also arranged inside the discharge vessel 14 shown in FIG. 2 . The discharge tube 14 is sealed from the outside. Electrodes 16 are in electrical contact with external connectors through molybdenum sheets 18 .

[0032] The diameter of the electrode shown in FIG. 2 is 900 μm, and the electrode is only used as an illustrative example, and is not scaled to exact dimensions. These electrodes consist of a tungsten rod around which a coil of tungsten filament is wound. Each coil includes 16 inner windings and 14 outer windings, where the diameter of the filament is 175 μm.

[0033] The electrode distance d shown in the examples is 1.5 mm.

[0034] The filling of the discharge vessel 14 consists of 30 mg of mercury, 35 nmol of bromine and 200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com