Front structure of vehicle

A front structure and vehicle technology, which is applied to the superstructure, vehicle components, superstructure sub-assemblies, etc., can solve the problems of easy dirtiness of the front pillar and door frame, improve sealing performance, prevent interference, and reduce air gap. effect of noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, preferred embodiments according to the present invention will be described based on the accompanying drawings.

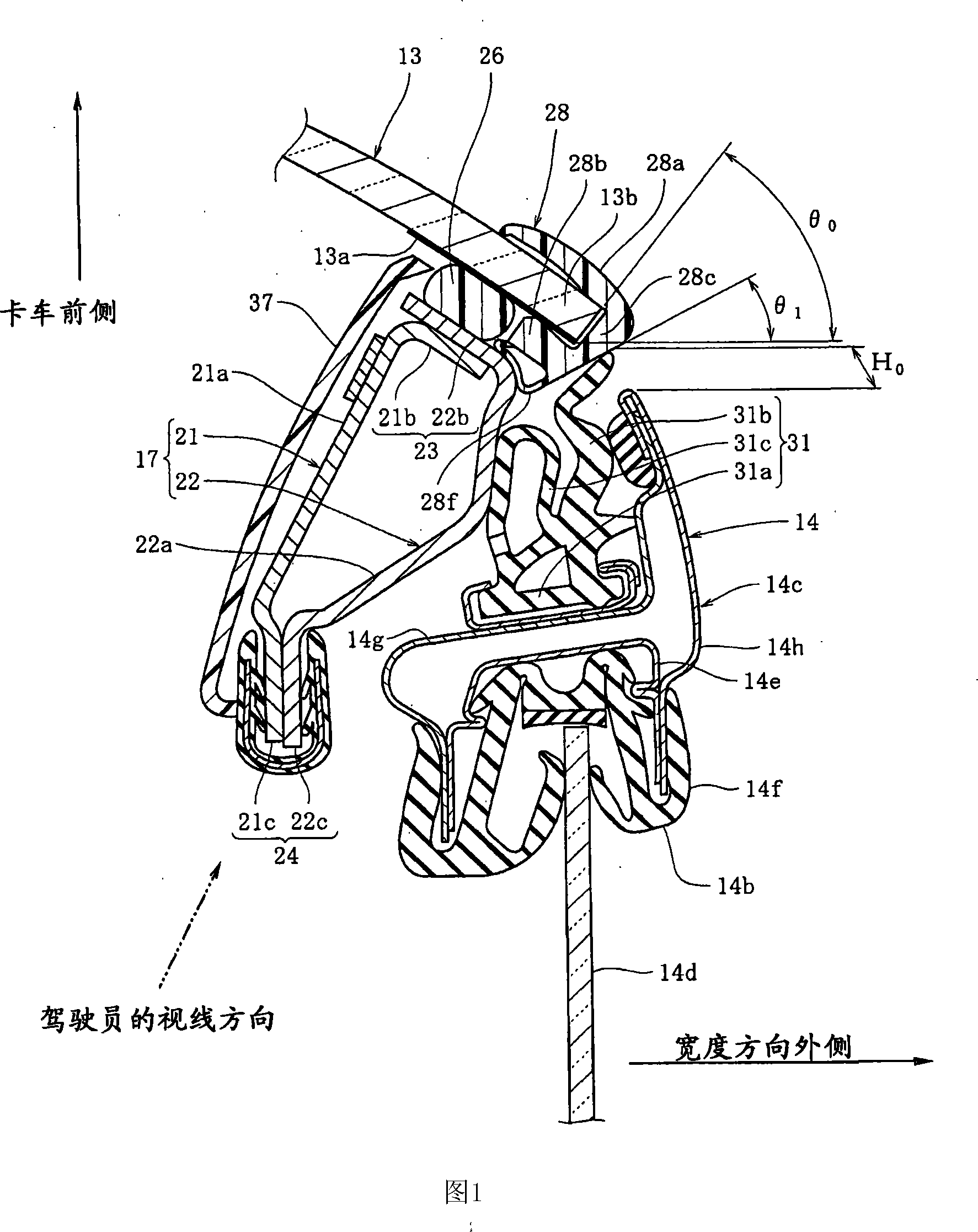

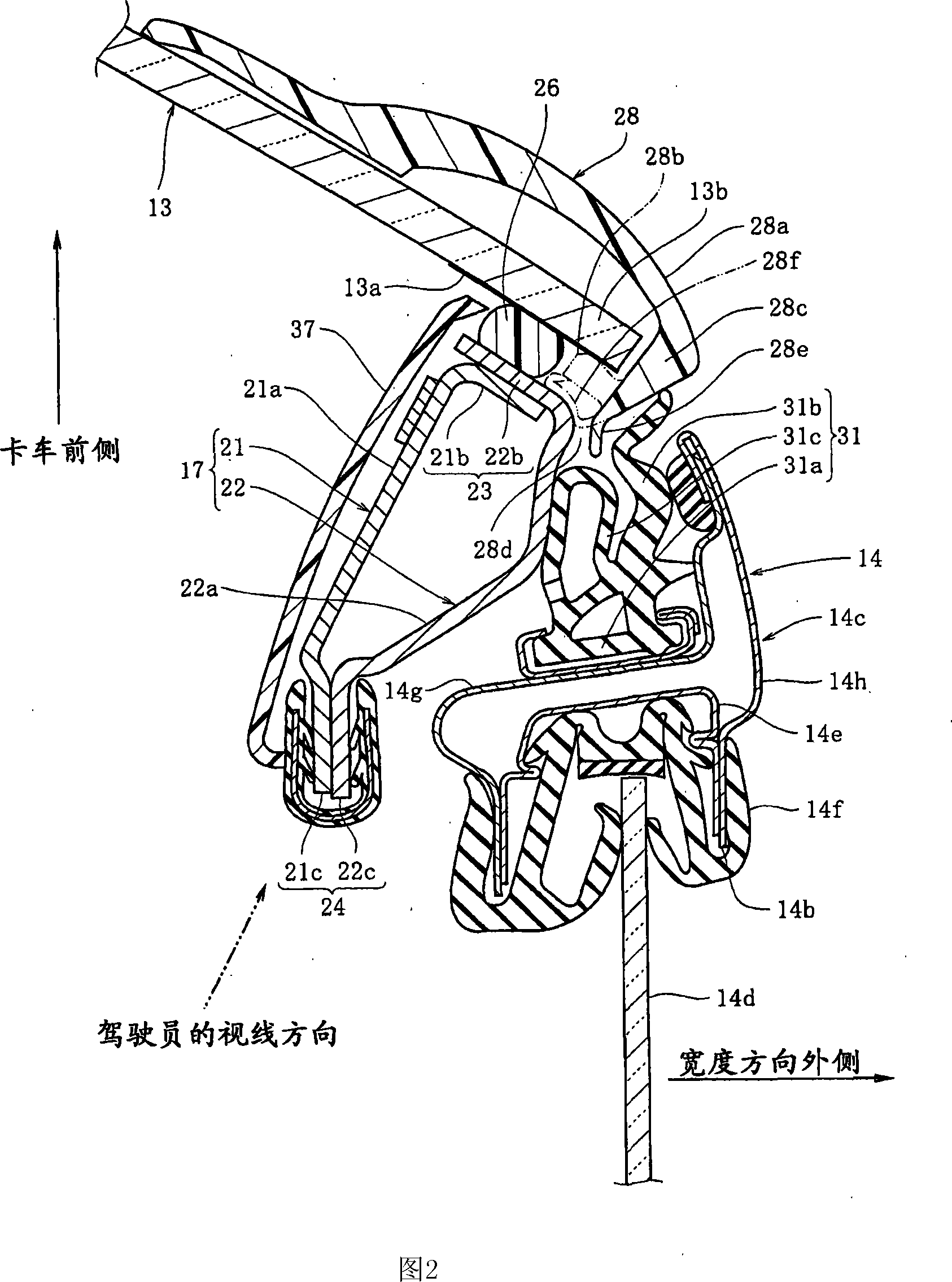

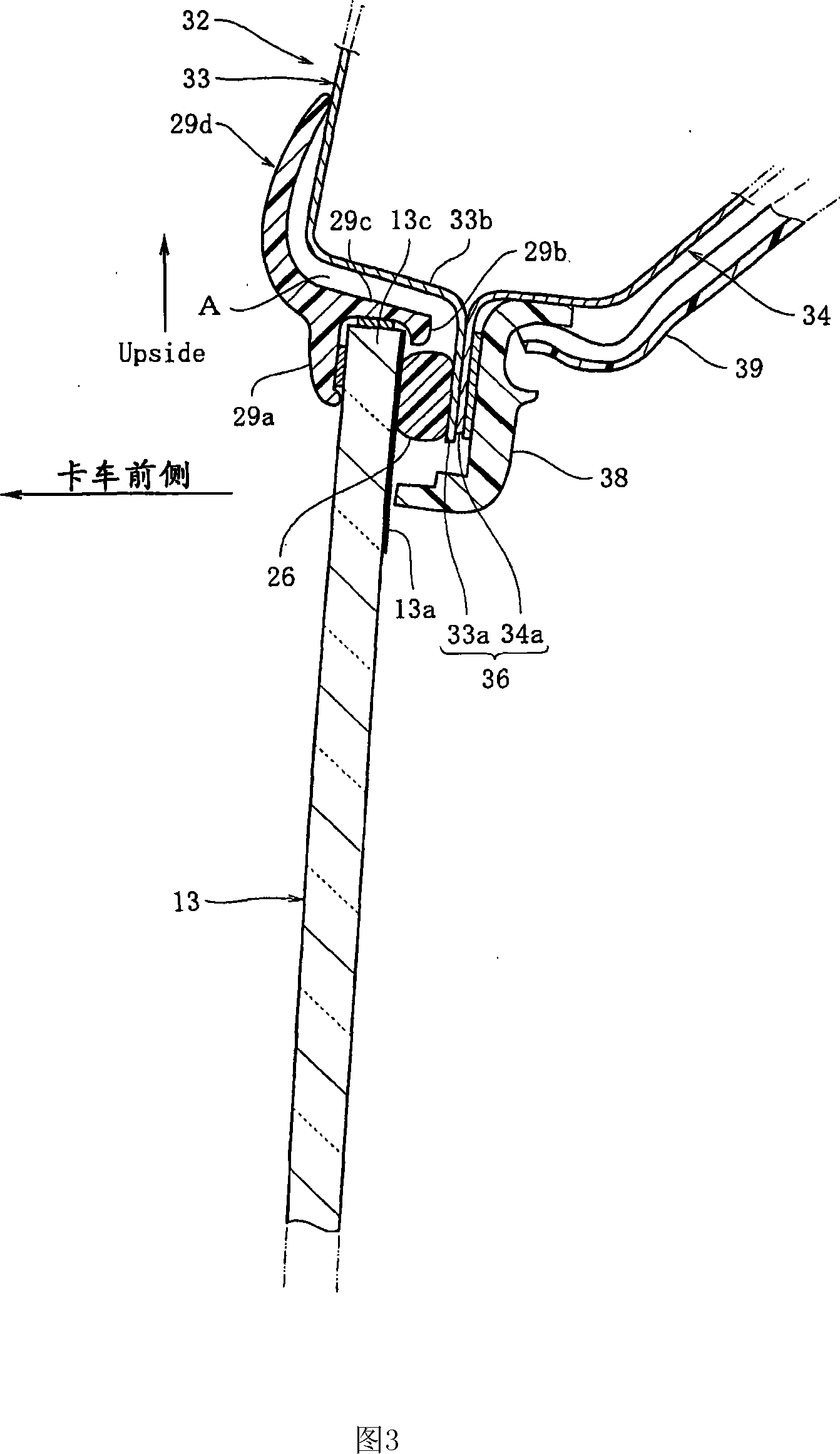

[0039] As shown in FIG. 8 , a driver's seat where the driver sits is provided on the right side of the cab 11 of the truck 10 , and the front opening 11 a on the front of the cab 11 is closed by a transparent windshield 13 . Also, a side opening 11b through which the driver gets on / off is provided on the side of the driver's seat side of the cab 11, and this side opening 11b is closed by a side door 14 capable of being kept open (FIGS. 1, 2 and 8) . The front pillar 17 is provided between the side of the windshield 13 and the front of the side door 14 and extends along the side of the glass 13 and the front of the door 14 . The front pillar 17 is formed into a cylindrical shape extending substantially in the vertical direction, for example, by joining together both side portions of the pillar inner panel 21 and both side portions of the pillar o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com