Vehicle lamp and method of manufacturing vehicle lamp

A manufacturing method and lamp technology, applied to road vehicles, household appliances, vehicle parts, etc., can solve problems such as poor joints, difficulty in obtaining designed shapes, and inability to perform welding, so as to prevent random refraction of welding light and prevent appearance deterioration , the effect of preventing shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Next, the best method for carrying out the vehicle lamp and the manufacturing method of the vehicle lamp according to the present invention will be described with reference to the drawings.

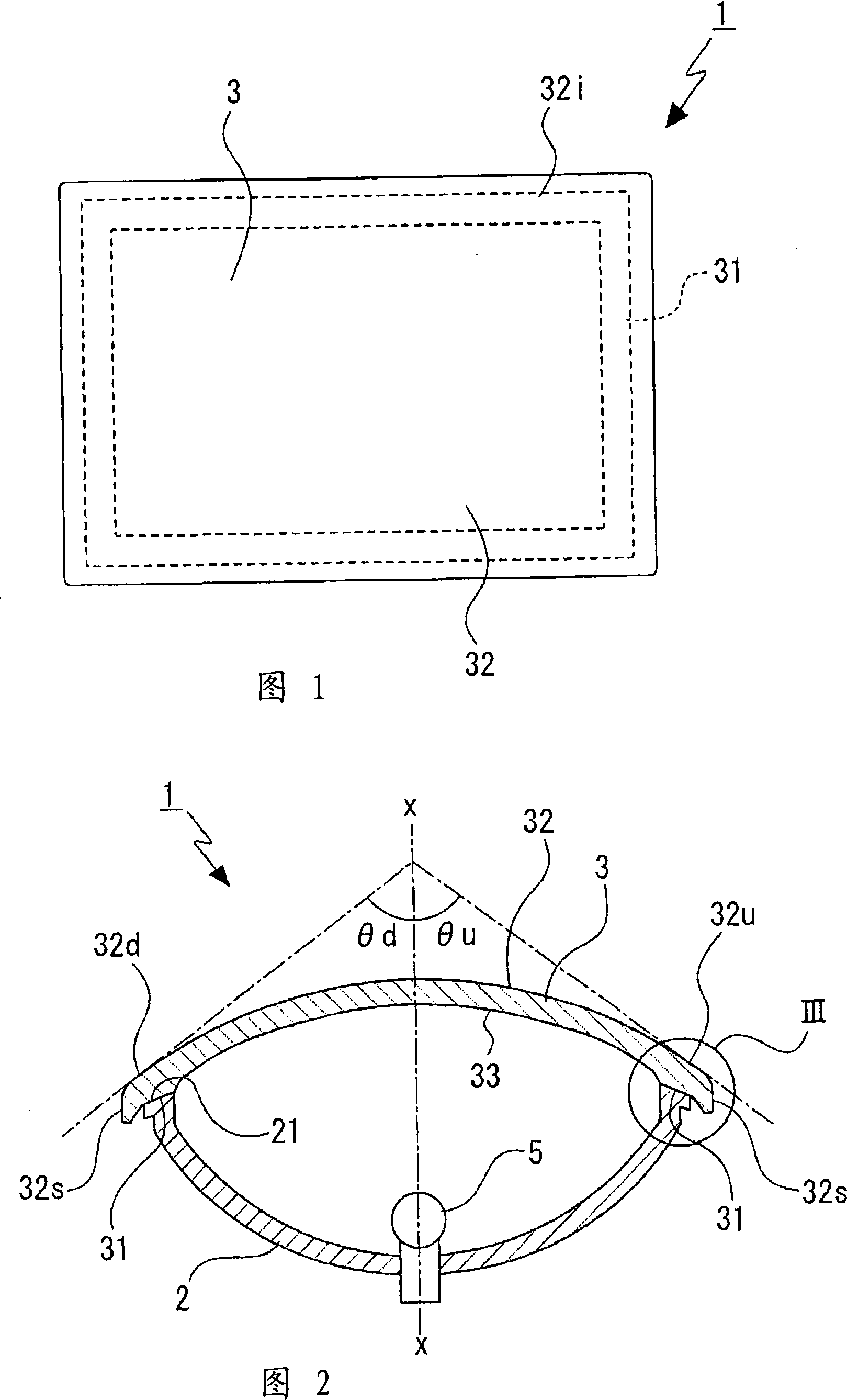

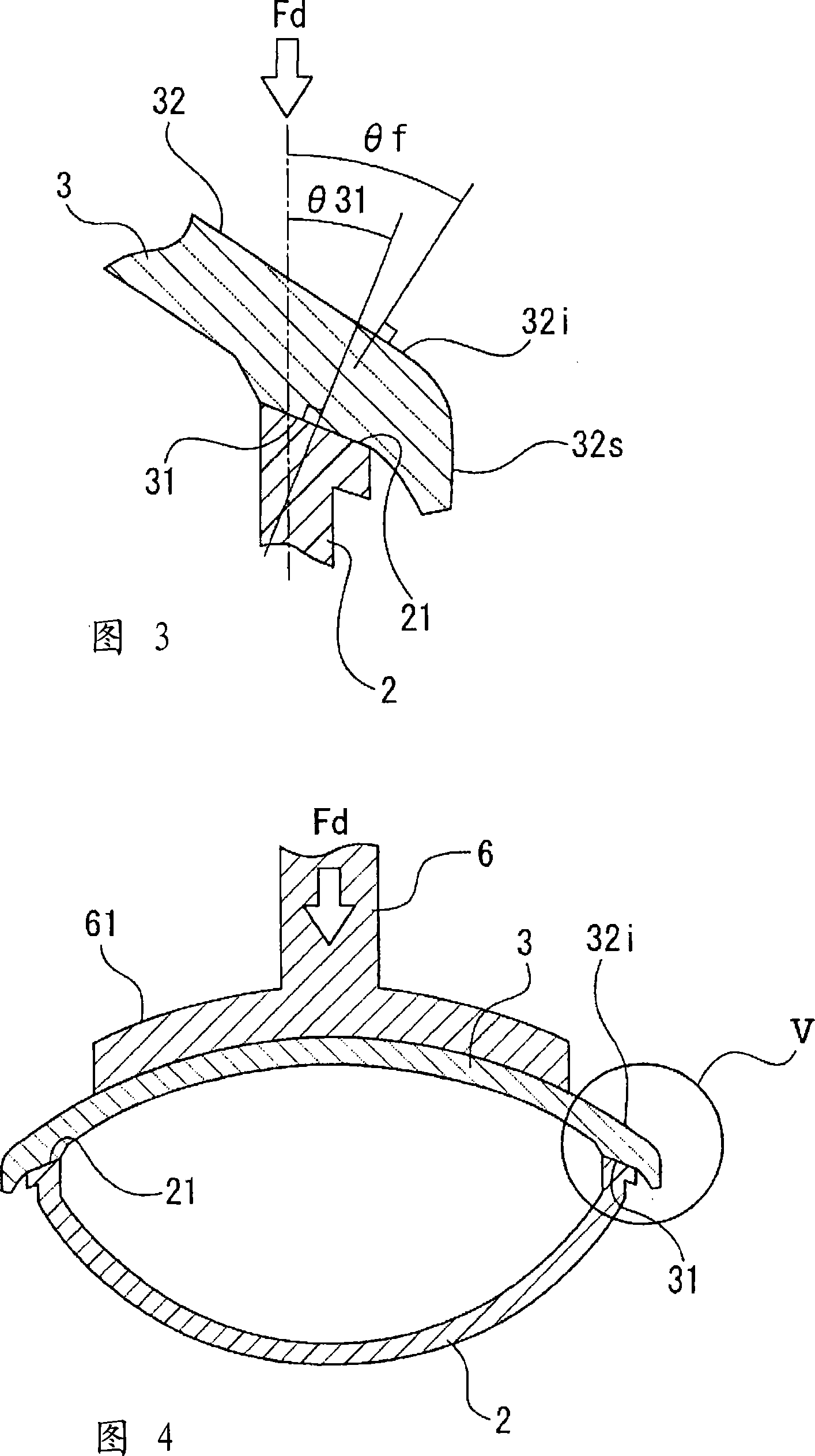

[0041] FIG. 1 shows a schematic front view of the vehicle lamp according to the present invention, and FIG. 2 shows a schematic longitudinal sectional view of the vehicle lamp according to the present invention.

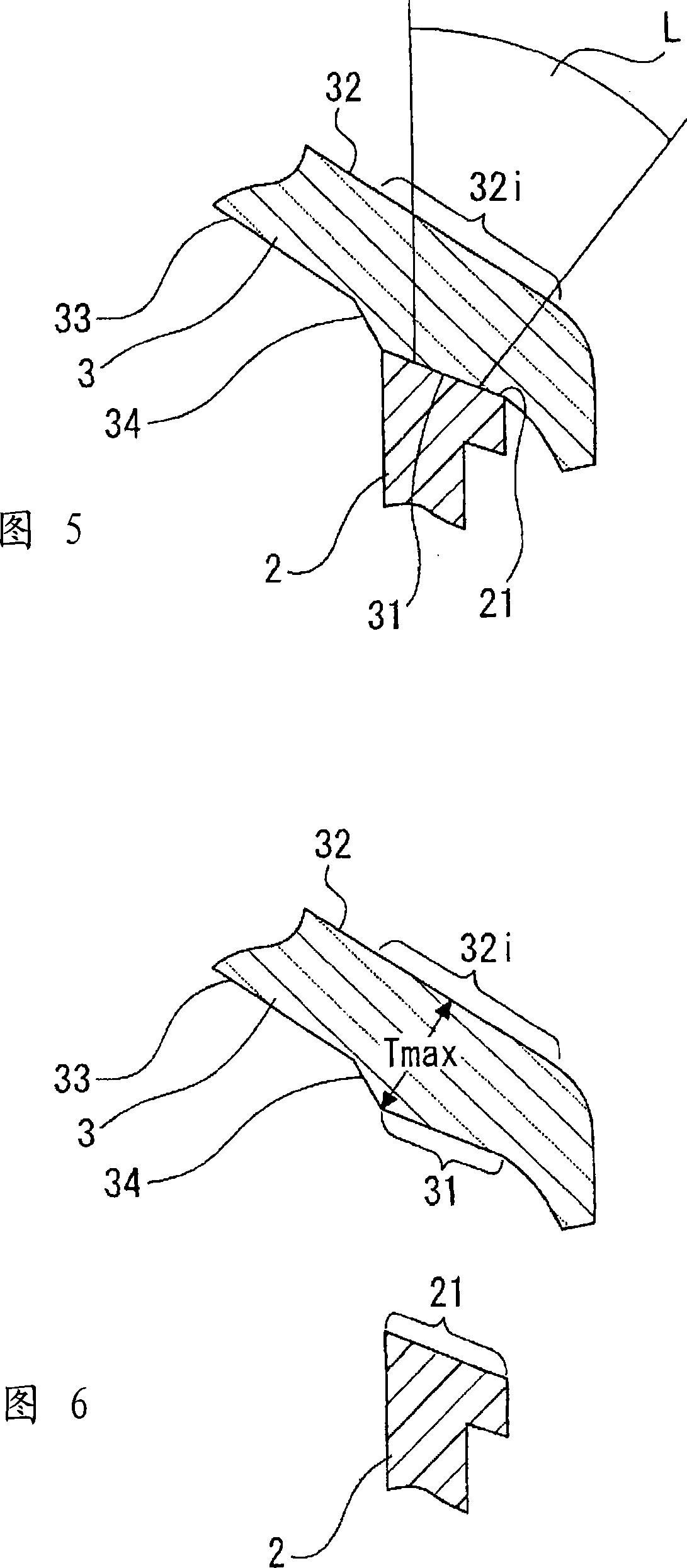

[0042] The vehicle lamp 1 is configured such that the front opening of a container-shaped case 2 with an open front is covered by a transparent cover 3 , and a light source 5 is arranged in a lamp chamber 4 defined by the case 2 and the transparent cover 3 .

[0043] On the rear of the peripheral portion of the transparent cover 3, a welding surface 31 is formed on the entire circumference, and the welding surface 31 is welded to the welding surface 21 formed on the peripheral portion of the front opening of the case 2 by beam welding. That is, the welding of welding ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com