Steam vacuum cleaner and its push bar assembly and hose assembly

A vacuum cleaner and assembly technology, applied in the installation of vacuum cleaners, suction hoses, electrical equipment, etc., can solve the problems of inconvenient transportation, large product volume, inability to separate, etc., to achieve convenient transportation, reduced packaging volume, The effect of preventing the wire from shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Examples of the present invention will be described below with reference to the accompanying drawings. For the same parts as the prior art, please refer to the related materials of the prior art, and no detailed description will be given.

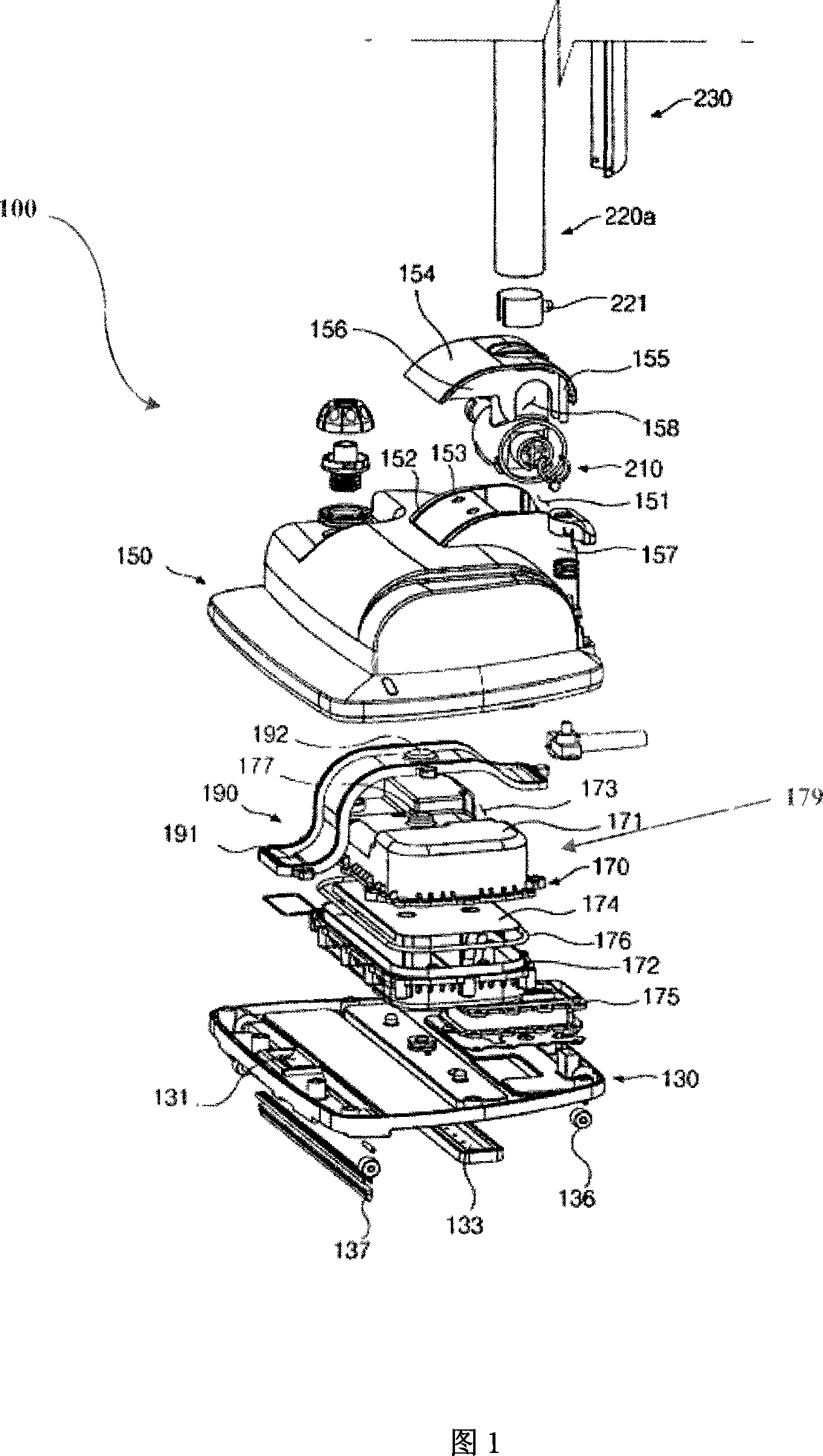

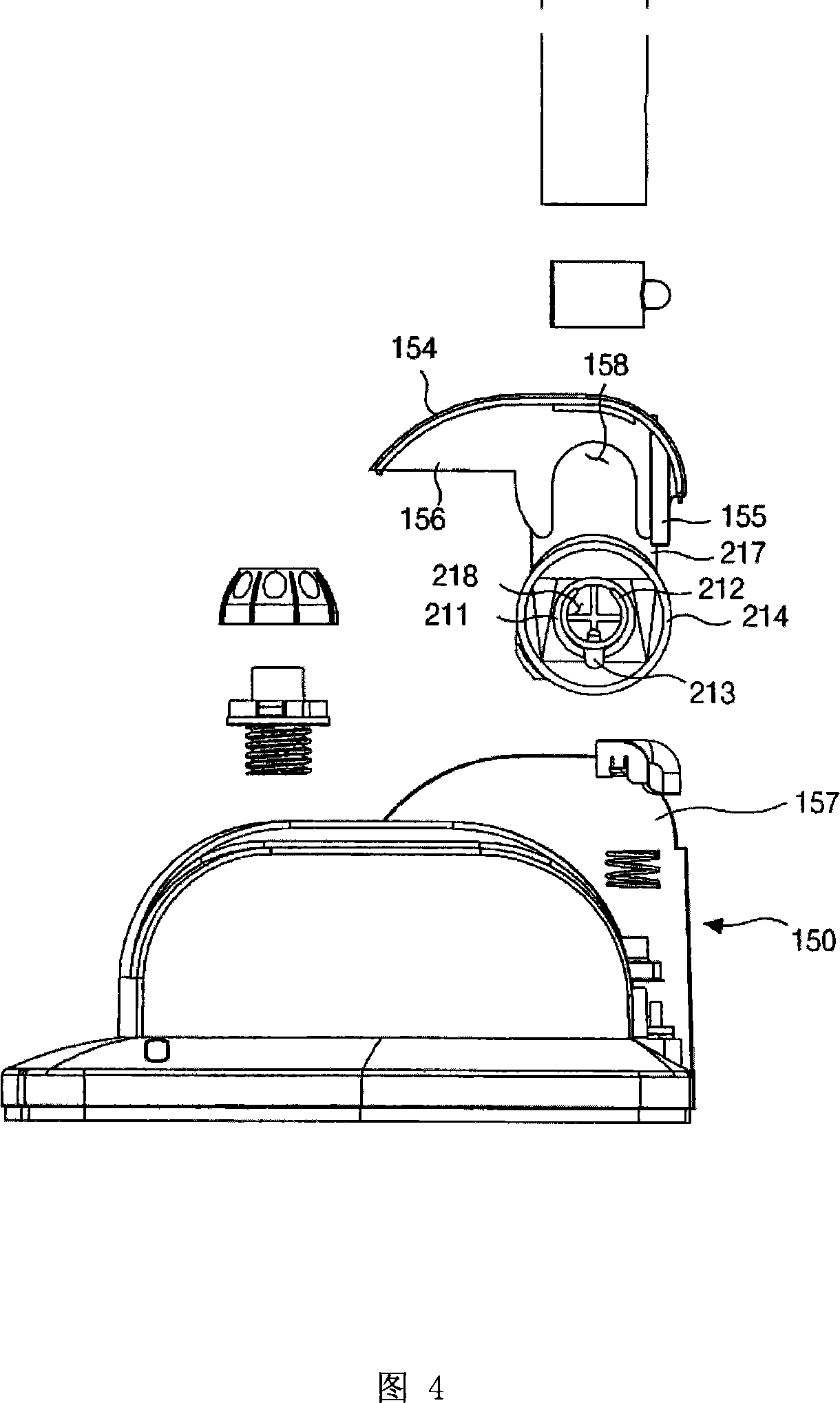

[0034] The steam vacuum cleaner according to the present invention includes a cleaner body, a hose assembly whose one end is detachably connected to the vacuum cleaner body, and a push rod assembly detachably connected to the other end of the hose assembly. . The floor brush 100 is detachably connected with the push rod assembly and has a steam generating device 170 . The push rod assembly has a first wire 250 that is detachably connected to the floor brush, and the hose assembly has a second wire 350 that is detachably connected to the vacuum cleaner body. The first wire 250 and the second wire 350 are detachably connected.

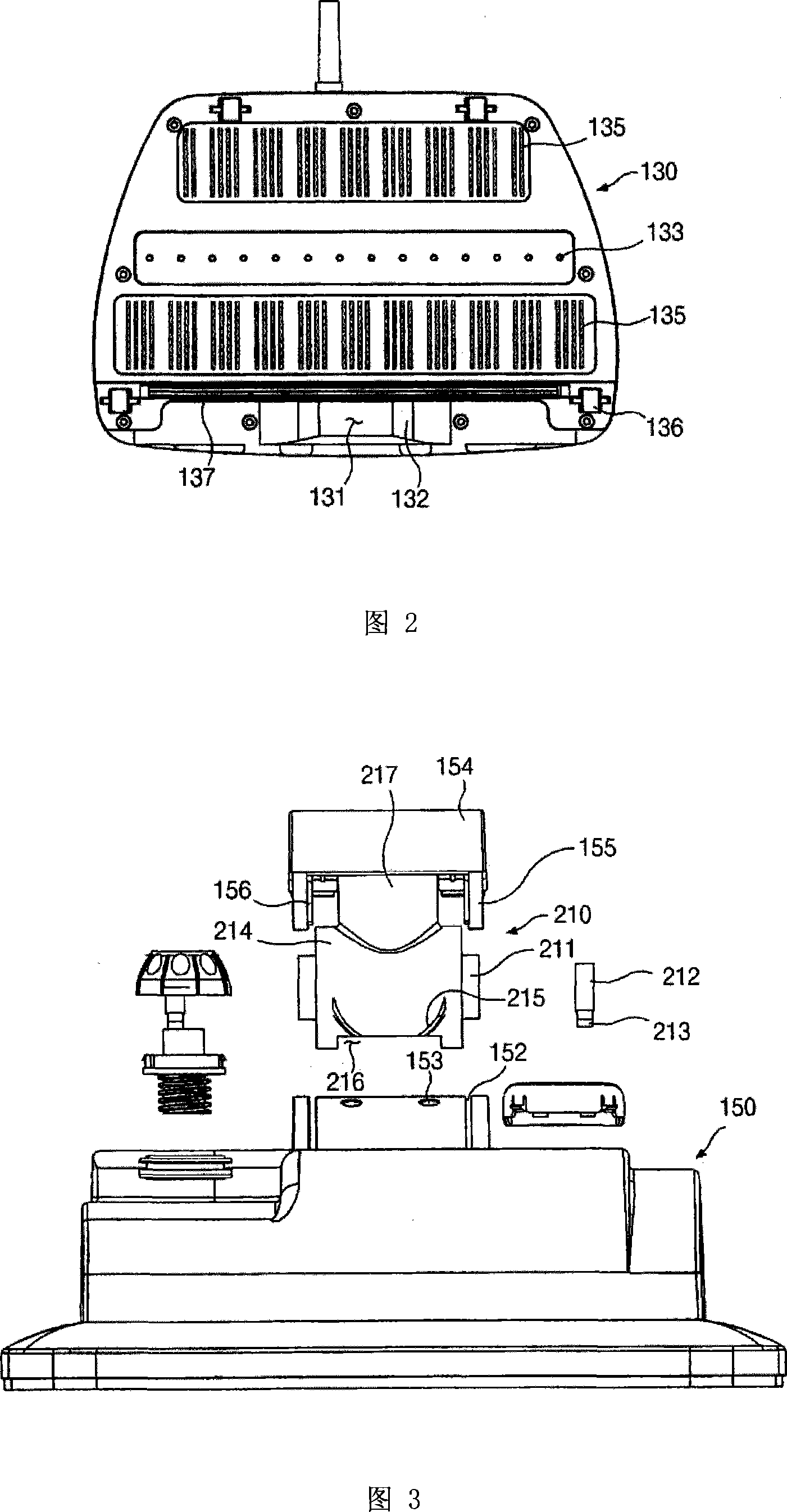

[0035]As shown in FIG. 1 , the floor brush 100 includes a casing 140 , a steam generating device 170 insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com