Defect detecting device and defect detecting method

A defect inspection and defect technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems that the workpiece cannot be transported, and the delivery period cannot be shortened, so as to achieve the effect of shortening the delivery period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

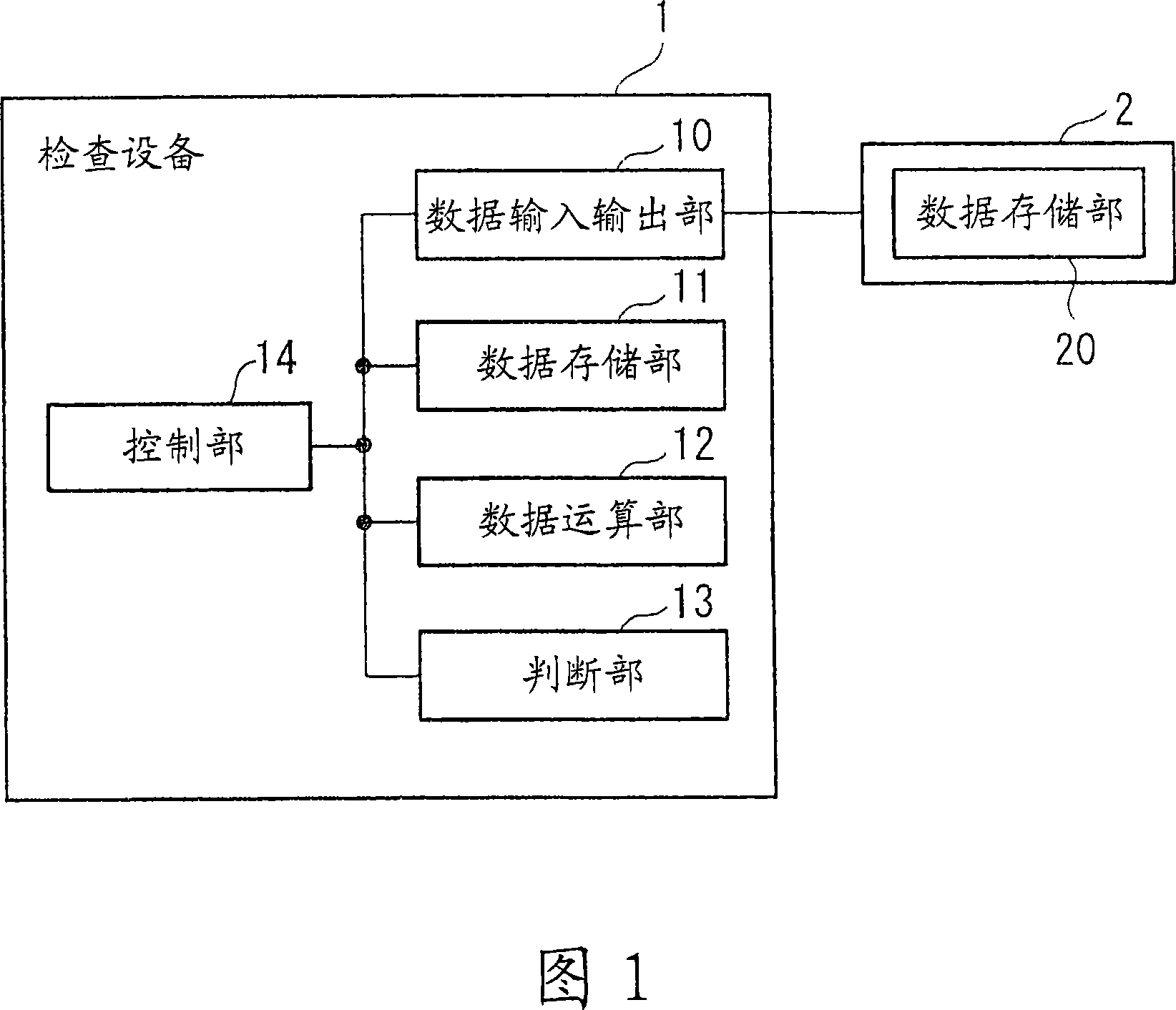

[0016] Hereinafter, preferred modes for implementing the present invention will be described with reference to the drawings. FIG. 1 is a block diagram showing the configuration of a defect inspection device according to a first embodiment of the present invention. Each structure in the drawing will be described below. The inspection device 1 is a defect inspection device that detects defects by performing macroscopic inspection or microscopic inspection on an object manufactured by sequentially laminating multiple layers on the surface by a photolithography process, such as a semiconductor wafer substrate or a glass substrate for liquid crystal display. The external device 2 is a server or the like having a data storage unit 20 which stores defect information and the like generated during inspection. The defect information includes defect position information indicating the position (coordinates) of a defect, defect type information indicating a type of defect, and the like. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com