Method for manufacturing display panel

A technology for a display panel and a manufacturing method, which is applied in the manufacture of semiconductor/solid-state devices, lighting devices, light sources, etc., can solve the problems of overflow of sealant, contamination of internal components in the display area, etc., and achieve the effect of avoiding contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

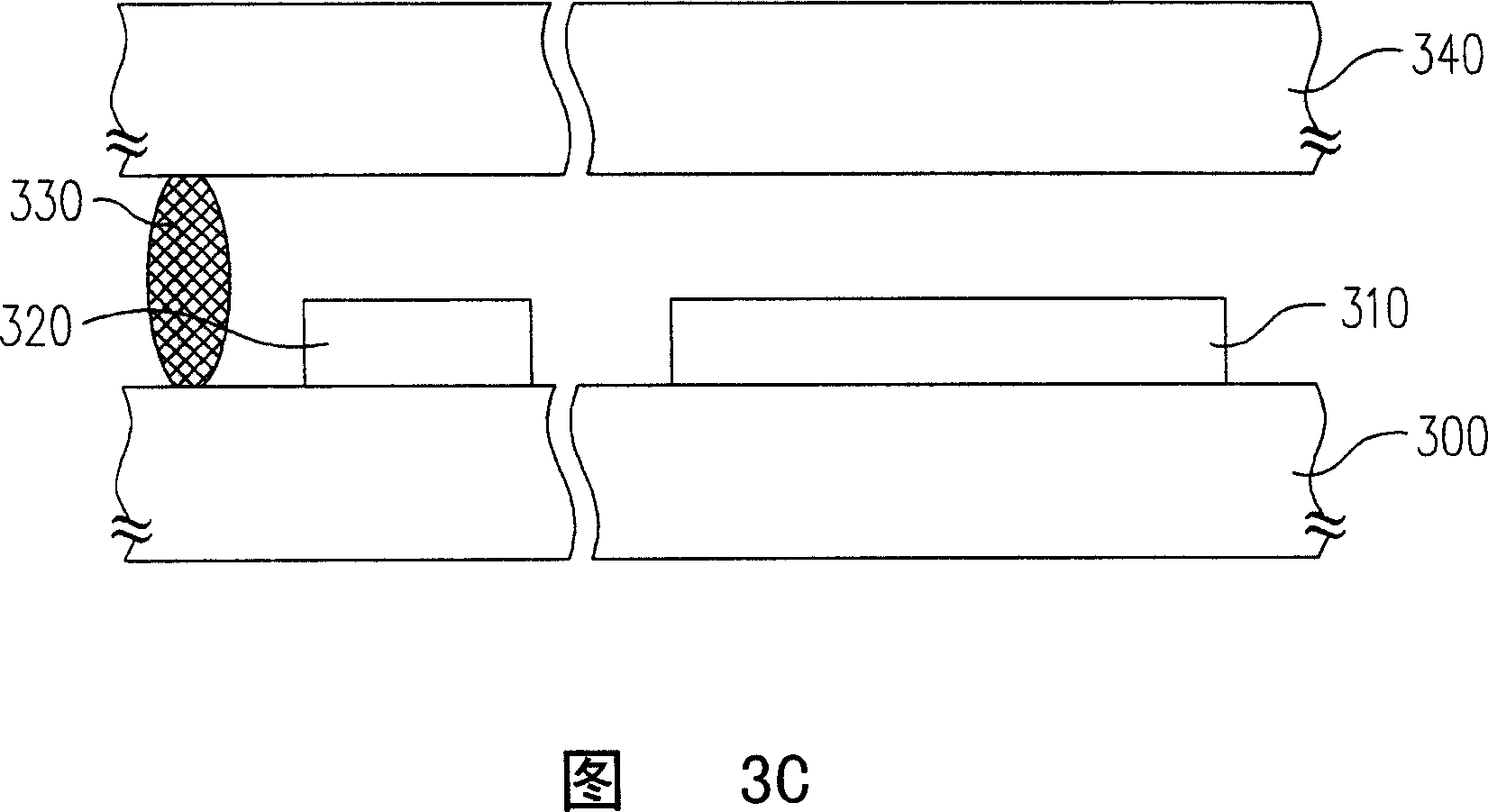

[0038]3A to 3C are cross-sectional views of the manufacturing process of the display panel in a preferred embodiment of the present invention. Referring to FIG. 3A , firstly, the pixel array 310 and the barrier layer 320 are formed on the first substrate 300 at the same time. Wherein, the first substrate 300 has a non-display area 302 and a display area 304, and the pixel array 310 is formed in the display area 304, and the blocking layer 320 is formed in the non-display area 302 and surrounds the pixel array 310. .

[0039] It is worth noting that the manufacturing process provided by the present invention can be used to manufacture liquid crystal display panels or organic electroluminescent display panels, and those of ordinary skill in the art should know that different types of display panels have different elements constituting their pixel arrays. . The steps of forming the pixel array 310 in the manufacturing process of the liquid crystal display panel and the organic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com