Pick-and-place machine comprising a locking device for coupling a feeding unit to it

A technology of interlocking mechanism and conveying device, applied in the direction of electrical components, electrical components, etc., can solve problems such as loss of data, and achieve the effect of improving operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

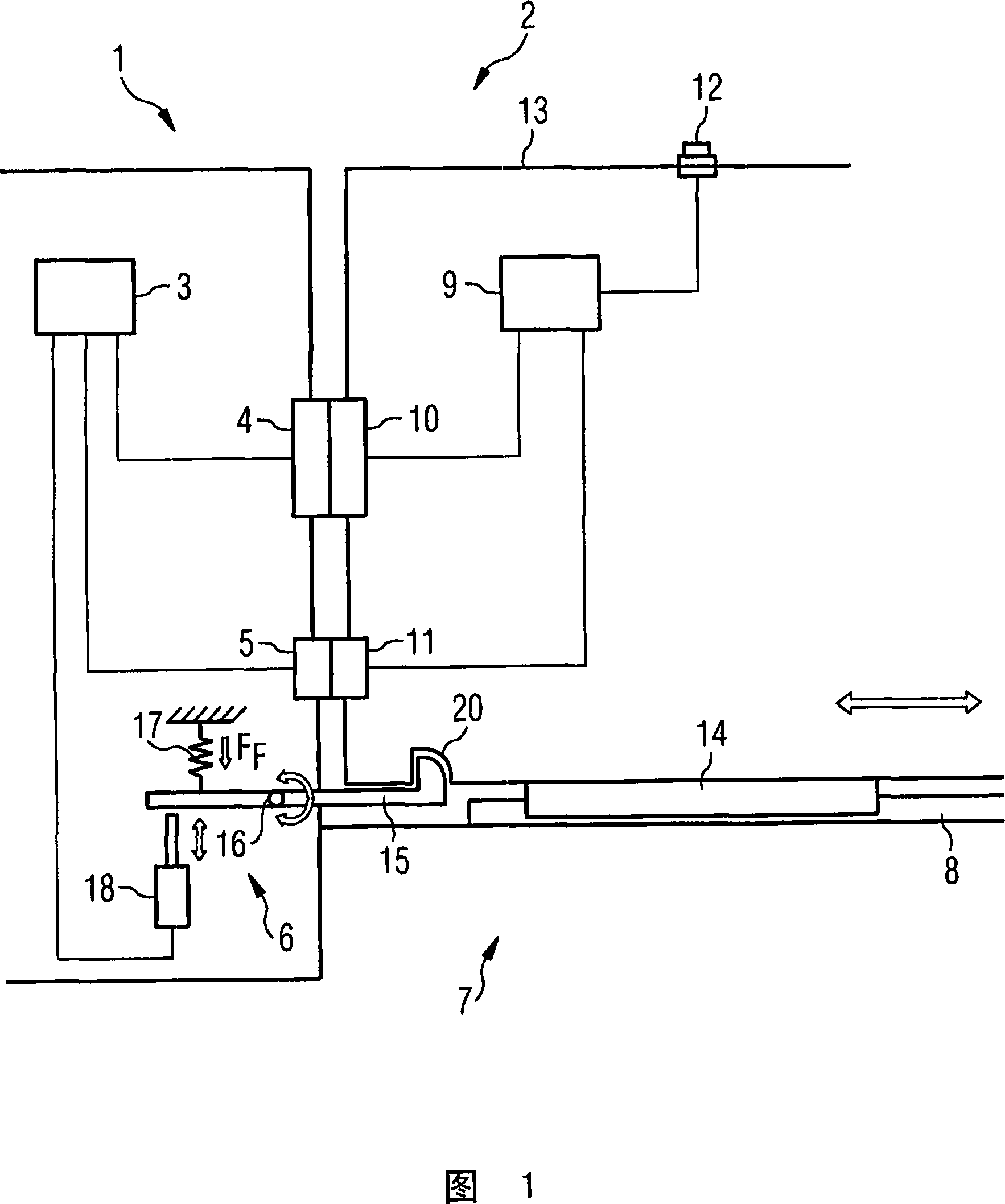

[0025] FIG. 1 shows the main components of an exemplary embodiment of an automatic assembly machine 1 according to the invention, to which a conveyor device 2 according to the invention is coupled. The automatic assembly machine 1 (shown on the left in FIG. 1 ) has a first control device 3 , a first data interface 4 , a first energy interface 5 and a coupling device 2 (shown on the right in FIG. 1 ). out) interlock mechanism 6. Both the first energy connection 5 and the first data connection 4 are electrically connected to the first control device 3 . Furthermore, the first control device 3 is electrically connected to the assembly head and the positioning system of the assembly head (both are not shown). Furthermore, the automatic assembly machine 1 comprises a table 7 for fastening the conveyor devices 2 , on the upper side of which table 7 guide rails 8 for one or more conveyor devices 2 are arranged.

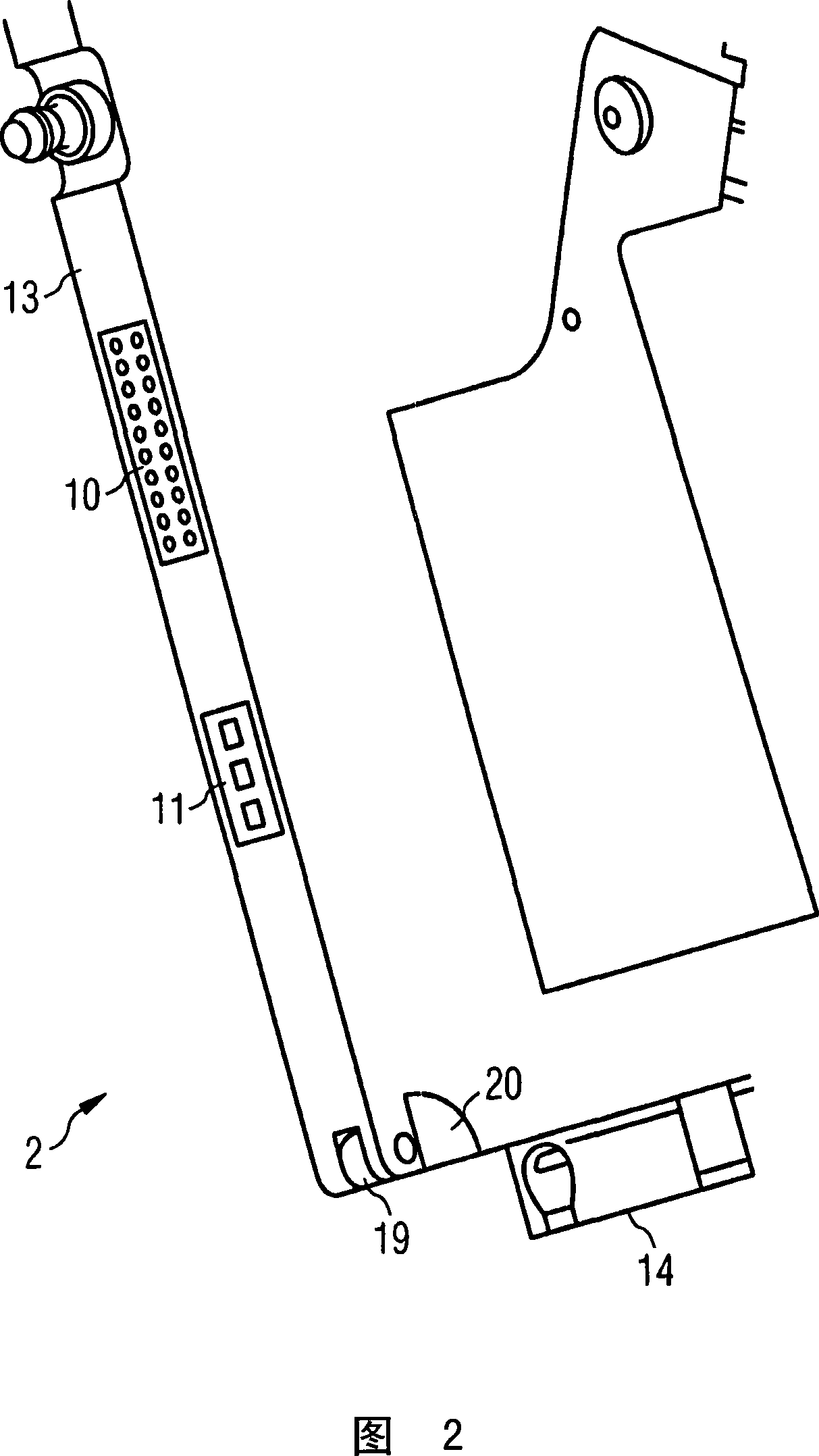

[0026] The delivery device 2 according to the invention itself has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com