Multifunctional detecting device for engine

A detection device and multi-functional technology, which is applied in the field of multi-function detection devices for engines, can solve problems such as complicated wiring, achieve cost-effective, improve thermal conductivity, and increase the degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

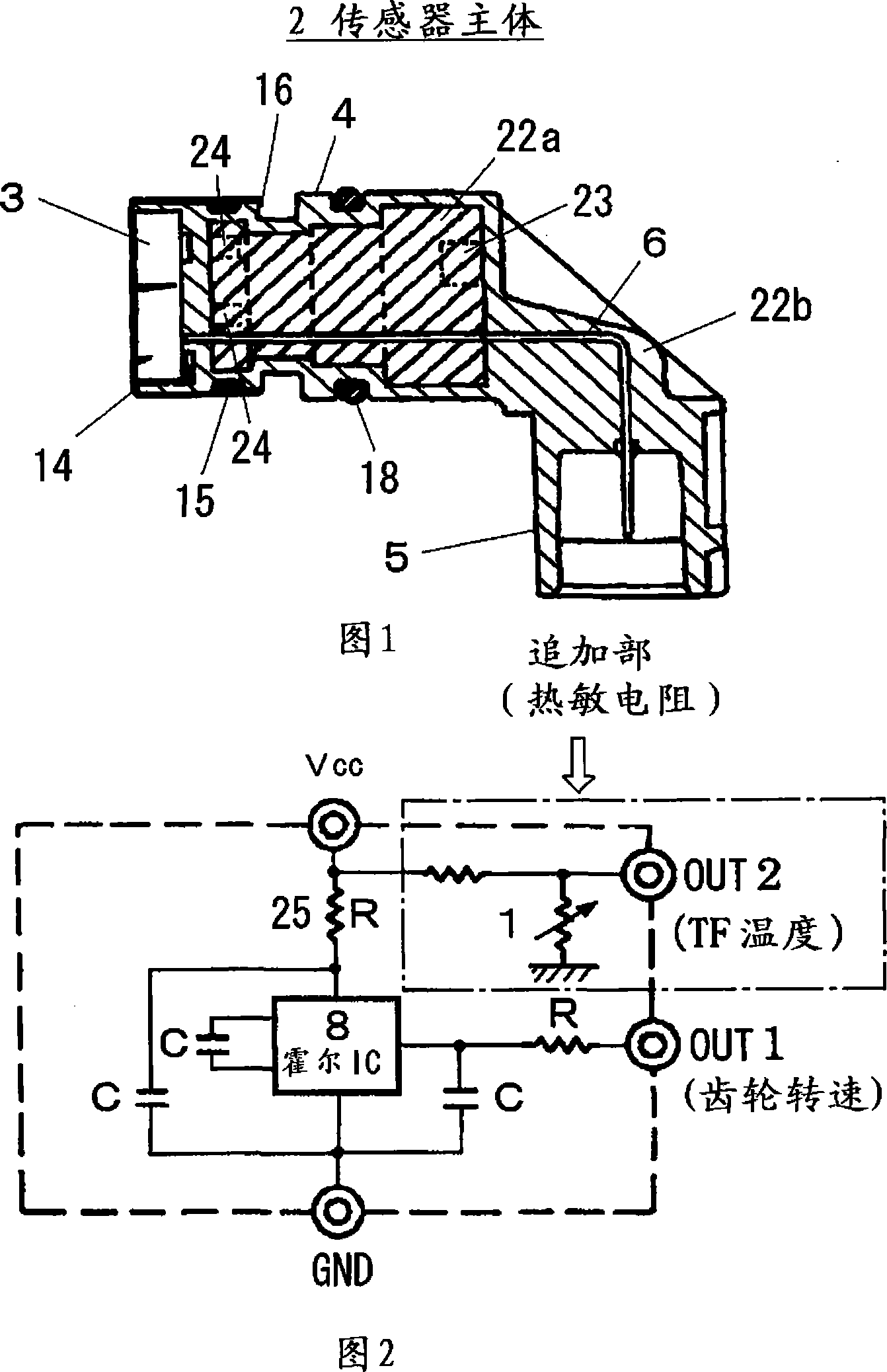

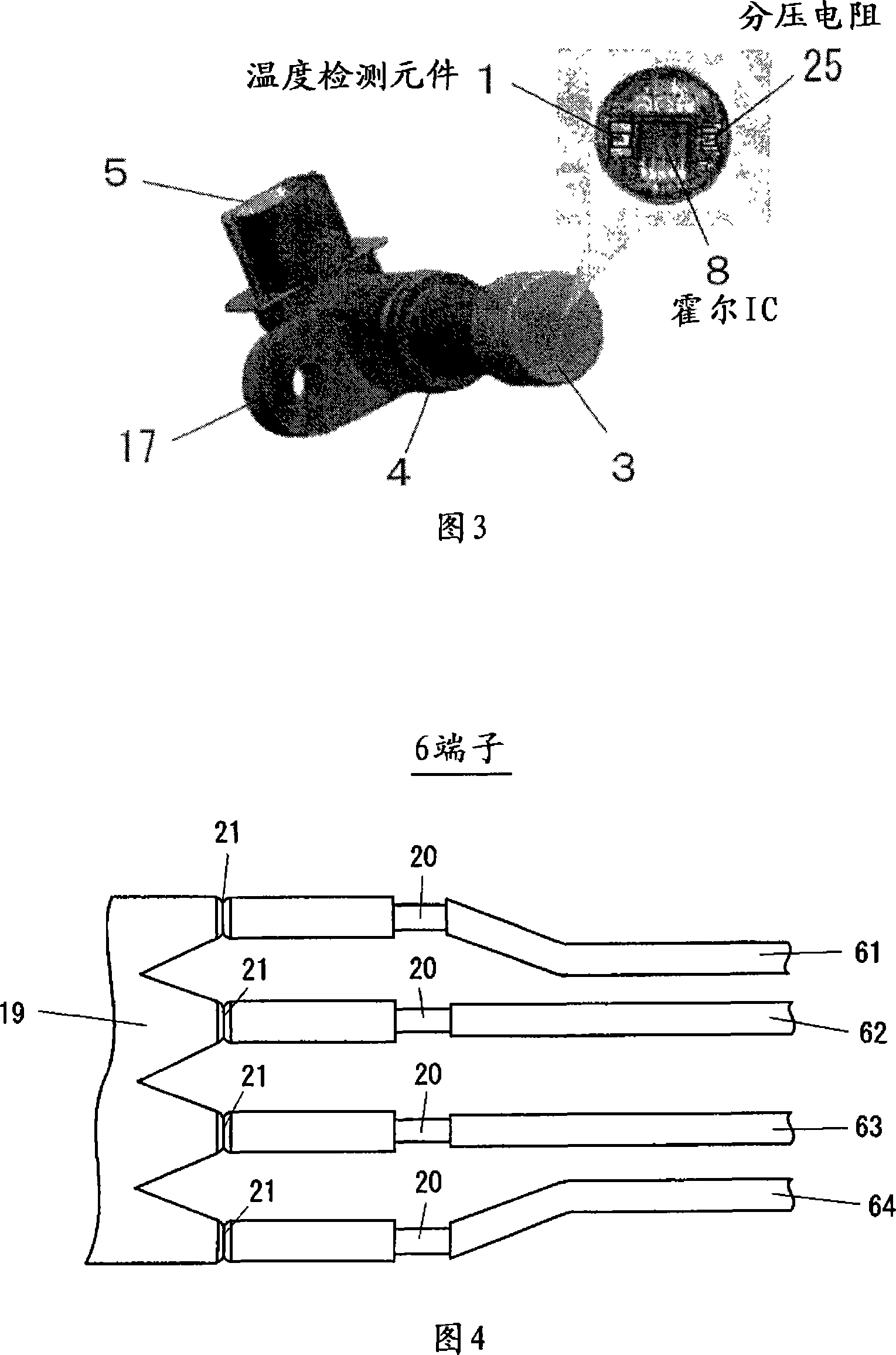

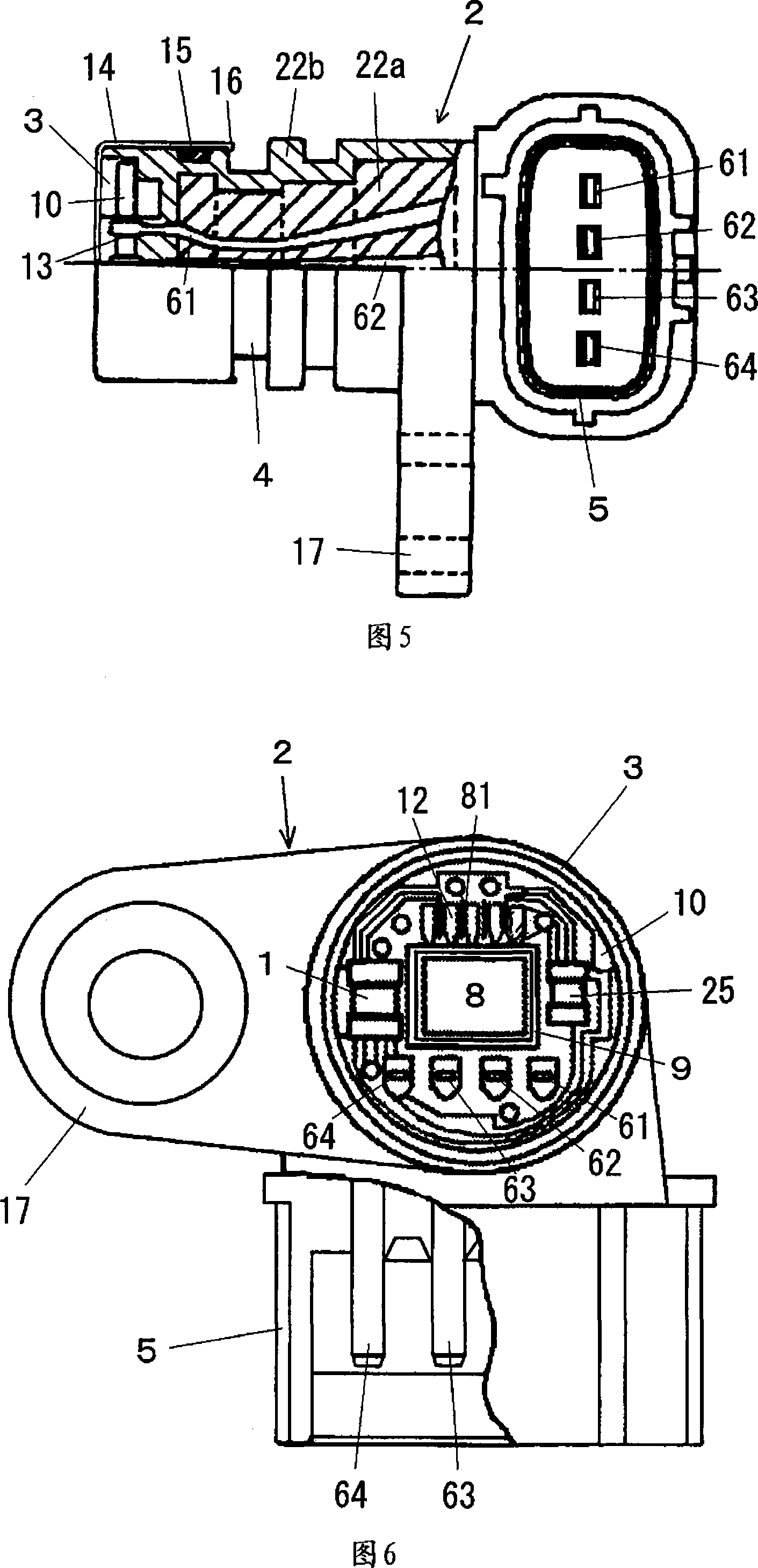

[0028]An embodiment of a multi-function detection device for an engine according to the present invention will be described with reference to FIGS. 1 to 6 . Fig. 1 is a front sectional view of this embodiment, in which, 2 is the sensor main body, 3 is the sensor storage chamber, 4 is the case part, 5 is the connector part, 6 is the external lead terminal, and 22a is the one-time molding Body, 22b is a secondary compression molded body. At one end of the sensor body 2 is disposed a sensor housing portion 3 for housing a sensor circuit board in which two sensors and other components are disposed, and a connector 5 is disposed at the other end of the sensor body 2 . As can be seen from the plan view shown in FIG. 3 , the external shape of the multifunctional detection device for an engine of the present invention is constituted such that the sensor main body 2 of the rotation detector is integrally made of resin via a shell portion 4 having a shape such as overlapping cylinders. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com