Magnetic power, method for manufacturing moulding powder and moulding powder

A powder magnetic core and magnetic powder technology, which is applied in the manufacture of inductors/transformers/magnets, magnetic cores/yokes, and the magnetism of inorganic materials, can solve problems such as the increase in the resistance value of powder magnetic cores, and achieve suppression of hysteresis loss and suppression Effect of eddy current loss and improvement of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050]

[0051] [powder]

[0052] As the spherical soft magnetic powder, a gas atomized powder composed of pure iron and having an average particle diameter of 100 μm was prepared.

[0053] [Preparation of treatment liquid for coating]

[0054] A treatment liquid for forming an insulating coating on the surface of the water-atomized powder was prepared in the following procedure.

[0055] (1) 4 g of salt with high solubility in water and Nd acetate were introduced into 100 mL of water, and completely dissolved using a vibrator or an ultrasonic stirrer.

[0056] (2) Press to generate NdF 3 Slowly add an equivalent of the chemical reaction diluted to 10% hydrogen fluoride acid.

[0057] (3) For NdF that generates gelatinous precipitates 3 The solution was stirred with an ultrasonic stirrer for more than 1 hour.

[0058] (4) After centrifugation at a rotational speed of 4000 to 6000 r.p.m, the supernatant was removed, and substantially the same amount of methanol was added...

Embodiment 2

[0079] A dust core was produced in the same manner as in Example 1. The difference from Example 1 is that as the powder of the magnetic powder, the water-atomized powder was pulverized by a ball mill, the surface was flattened, and the powder was classified so that the average particle diameter was 150 μm. In addition, the evaluation method of the dust core of Example 2 was performed by the same evaluation method as Example 1. Table 1 shows the results.

Embodiment 3

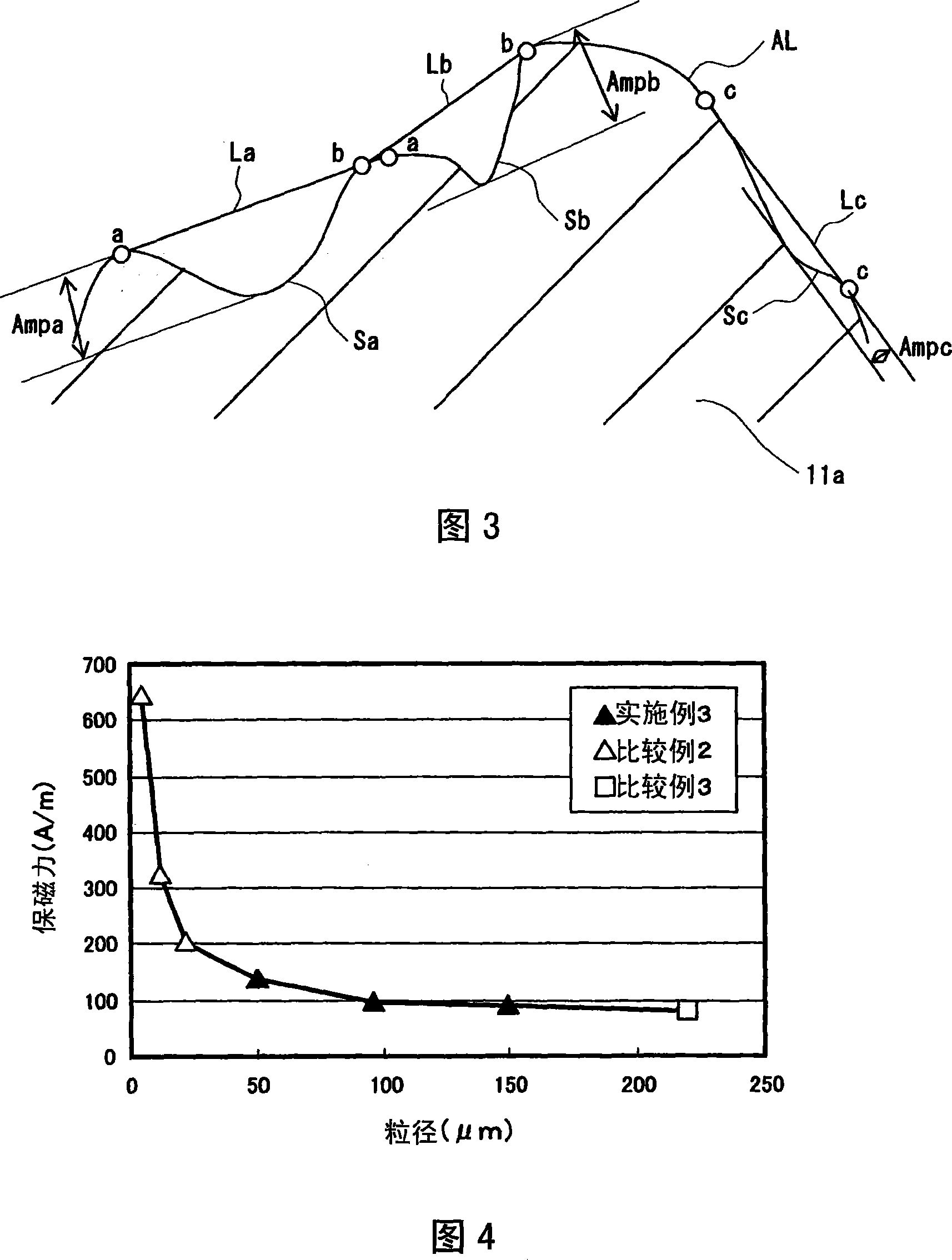

[0094] A dust core was produced in the same manner as in Example 1. The difference from Example 1 is that, as shown in FIG. 4 , as the soft magnetic powder, gas atomized powder classified by an average particle diameter of 50 μm to 200 μm was used, and NdF was carried out. 3 The layer formation treatment was performed by heat treatment at 600°C. In addition, the amount of powder used varies according to the size of the powder, so that NdF 3 The average thickness is consistent with 60 nm. Then, in the same manner as in Example 1, the coercive force of the dust core was measured. Figure 4 shows the results. In addition, the resistance value was also measured in the same manner as in Example 1. Figure 5 shows the results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com