Magnetic canister drive speed-adjusting clutch

A clutch and speed regulation technology, applied in the field of clutches, can solve the problems of high cost, high heat generation, small transmission torque, etc., and achieve the effects of low manufacturing, use and maintenance costs, small power loss, and large transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

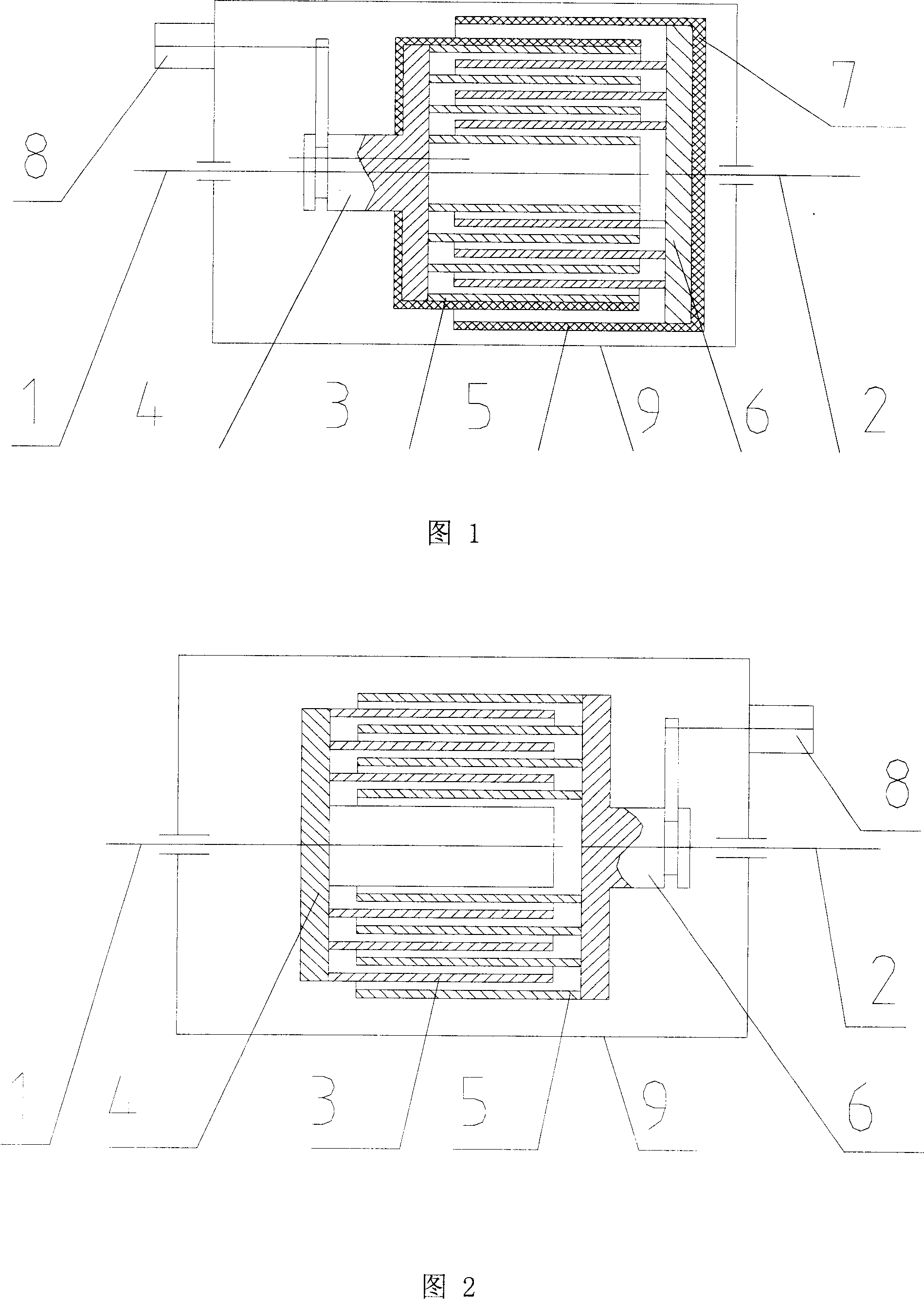

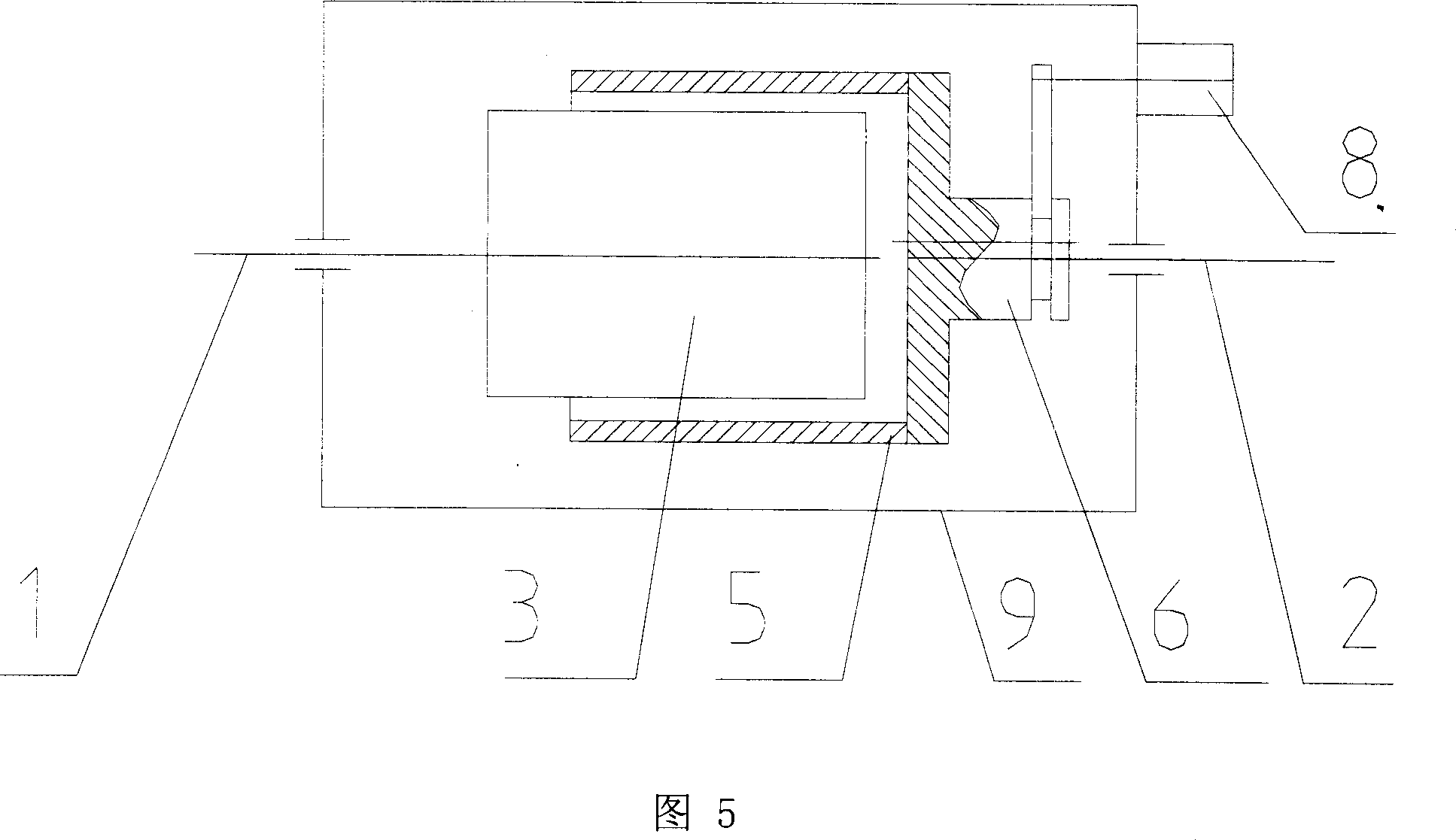

Embodiment 1

[0025] Please refer to shown in Fig. 1, the magnetic cylinder transmission speed regulating clutch of preferred embodiment of the present invention, comprises transmission shaft I (1), transmission shaft II (2), one or more than one transmission member I (3), fixed body I (4), one or more transmission parts II (5), fixed body II (6), magnetic isolation sleeve (7), adjustment mechanism (8), body (9), in which: transmission shaft I (1) The transmission shaft II (2) and the adjustment mechanism (8) are respectively installed on the body (9), the fixed body I (4) is installed on the transmission shaft I (1), and the fixed body II (6) is installed on the transmission shaft II ( 2), the transmission part I (3) and the transmission part II (5) are both cylindrical, and their diameters are different from each other. Any two pieces can be set together. The transmission part I (3) and the transmission part II (5) )--interlaced at intervals and coaxially installed on the fixed body I (4)...

Embodiment 2

[0029] Please refer to shown in Fig. 2, the magnetic cylinder transmission speed regulating clutch of preferred embodiment of the present invention, comprises transmission shaft I (1), transmission shaft II (2), one or more than one transmission member I (3), fixed body I (4), one or more transmission parts II (5), fixed body II (6), adjustment mechanism (8), body (9), wherein: transmission shaft I (1) and transmission shaft II (2) They are coaxially installed on the machine body (9), the fixed body I (4) is installed on the transmission shaft I (1), the fixed body II (6) is installed on the transmission shaft II (2), and the transmission part I ( 3) is a cylinder, the other transmission parts I (3) and all transmission parts II (5) are cylinders, all transmission parts I (3) and transmission parts II (5) have different diameters, and any two parts can Sleeved together, the transmission part I (3) and the transmission part II (5) are interlaced with each other at intervals and...

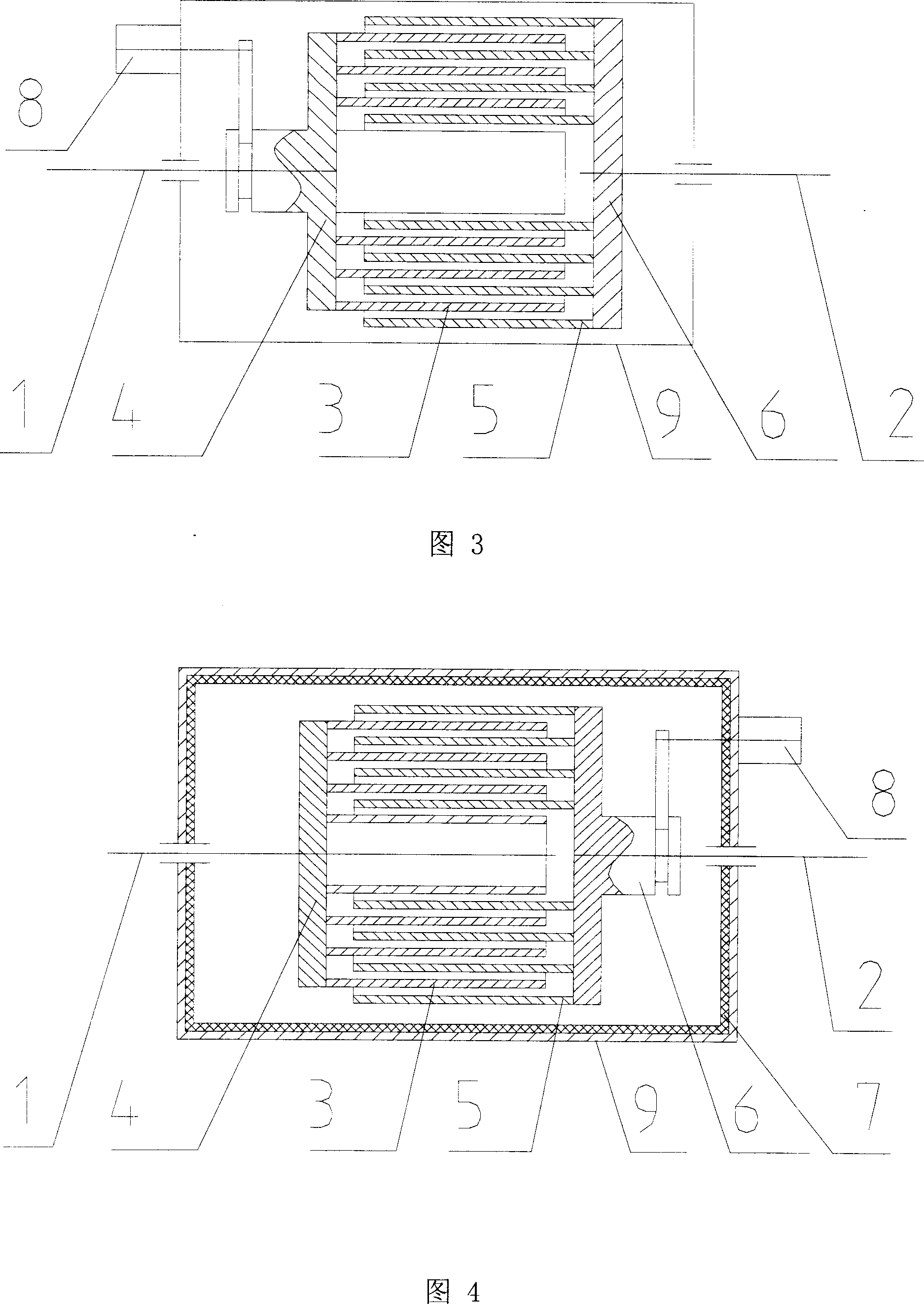

Embodiment 3

[0031]Please refer to shown in Fig. 3, the magnetic cylinder transmission speed regulating clutch of preferred embodiment of the present invention, comprises transmission shaft I (1), transmission shaft II (2), one or more than one transmission member I (3), fixed body I (4), one or more transmission parts II (5), fixed body II (6), adjustment mechanism (8), body (9), wherein: transmission shaft I (1) and transmission shaft II (2) The coaxial shafts are respectively installed on the body (9), the fixed body I (4) is installed on the transmission shaft I (1), the fixed body II (6) is installed on the transmission shaft II (2), except for the transmission part I with the smallest diameter (3) is a cylinder, and the rest of the transmission part I (3) and the transmission part II (5) are cylindrical, and their diameters are different from each other. Any two pieces can be set together. The transmission part I (3) and the transmission part Pieces II (5) are interlaced with each ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com