Processing method of high-accuracy herringbone gear without withdrawing groove hard tooth surface

A technology of no undercut, herringbone gear, applied in the direction of components with teeth, belt/chain/gear, gear teeth, etc., can solve the problems of grinding teeth, processing two gears to meet the specified requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

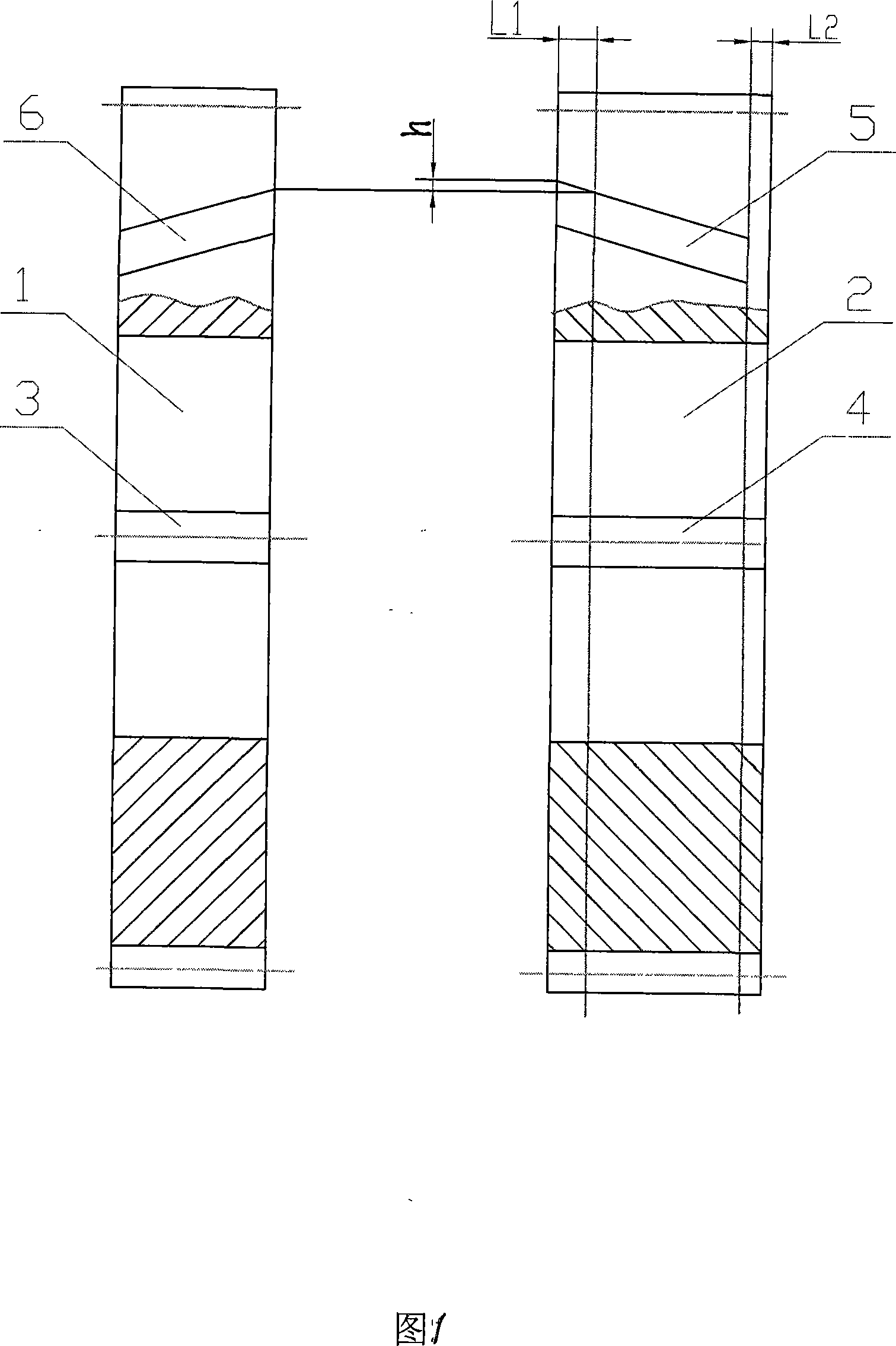

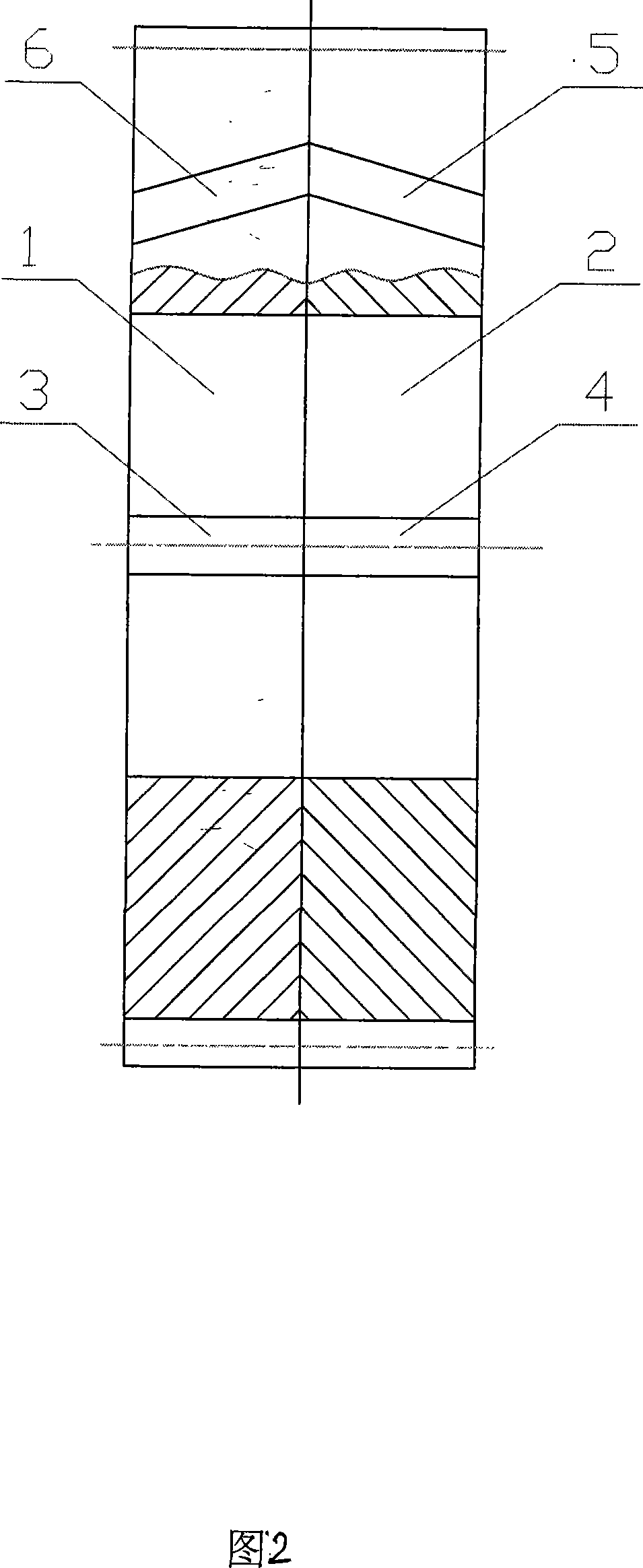

[0018] In an embodiment, in order to eliminate the errors that need to be centered as shown in FIG. 1 , the left-handed single helical gear 1 and the right-handed single helical gear 2 meet the centering requirements shown in FIG. 2 . Firstly, the finished left-handed single helical gear 1 is processed from the tooth blank by traditional gear technology, that is, the left-handed single helical gear 1 is processed according to the designed size through turning, hobbing, carburizing and quenching, finishing turning, key slotting, and gear grinding. Then, the right-handed single helical gear 2 is processed by traditional gear technology, but the grinding allowance L must be left on both ends of the gear. 1 , L 2 Then insert the keyway 3 of the left-handed single helical gear and the keyway 4 of the right-handed single helical gear with the flat key to combine t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com