Three-dimensional numerical control circular arc spherical surface processing machine

A technology of spherical surface processing and arc, which is applied in the field of three-dimensional CNC arc spherical surface processing machines, can solve the problems of high manufacturing cost, low production efficiency, and waste, so as to solve the problem of waste of raw materials, avoid waste of graphite blanks, The effect of solving the waste problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

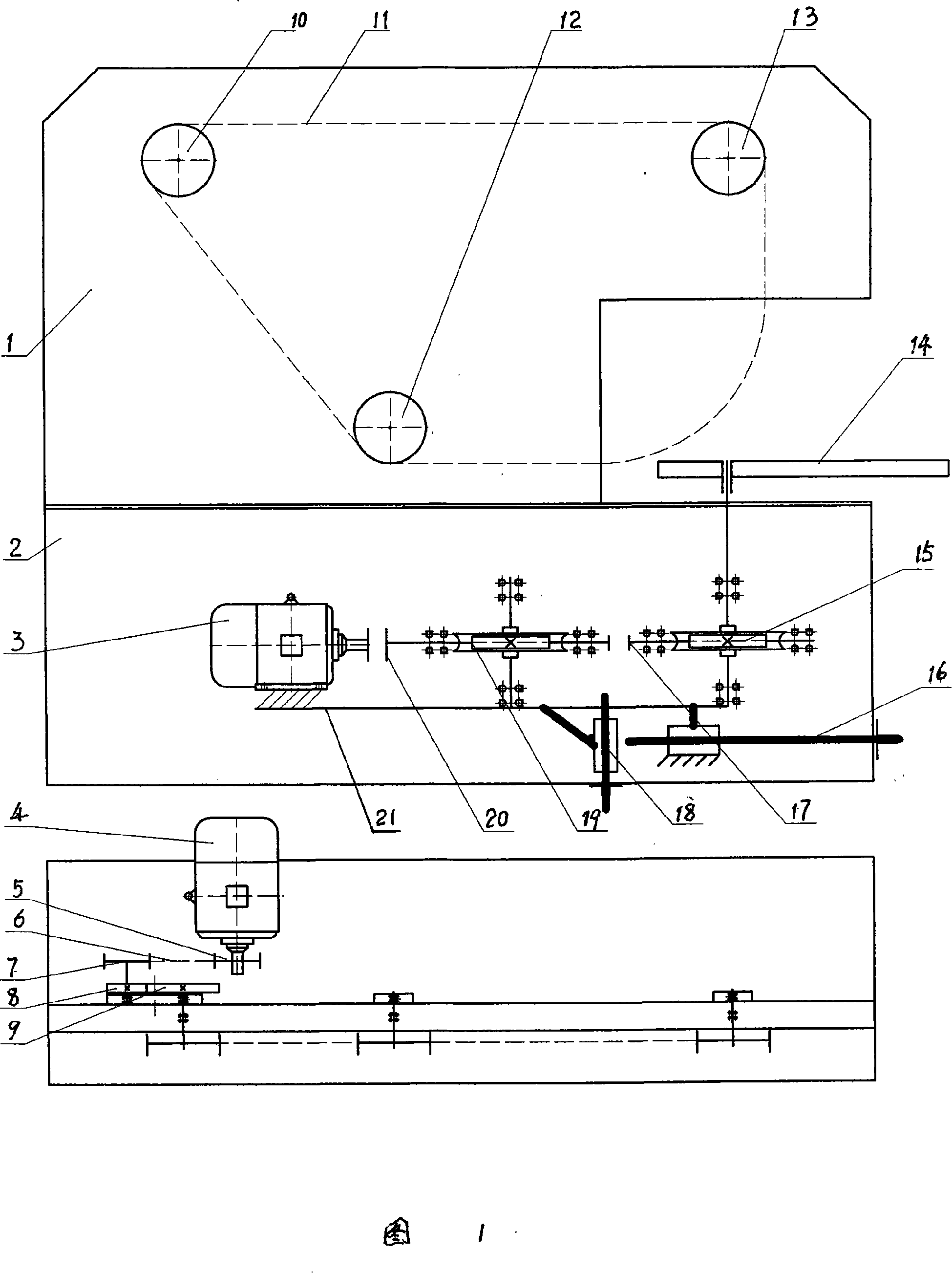

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0019] As shown in FIG. 1 , the present invention includes an upper body 1 and a lower body 2 connected to each other. The lower body 2 is provided with an auxiliary motor 3, the auxiliary motor 3 is connected to the first worm gear pair 19 through the first shaft coupling 20, and the first worm gear pair 19 is connected to the second worm gear pair 15 through the second shaft coupling 17. In the second worm gear A rotary table 14 is installed on the main shaft of the vice 15. Wherein, auxiliary motor 3, first worm gear pair 19 and second worm gear pair 15 are installed on the moving plate 21, and this moving plate 21 is connected with lower body 2 through horizontal moving mechanism 16 and vertical moving mechanism 18 respectively.

[0020] The main motor 4 is installed on the upper body 1, the first pulley 5 is housed on the motor shaft of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com