Label winding/setting mechanism

A label roll and roll label technology, applied in the direction of coating, etc., can solve the problems of poor yield rate of finished products, stripping or deviation, unsolved label entering the forming mold, etc., to achieve the effect of accurate combination and improve product yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

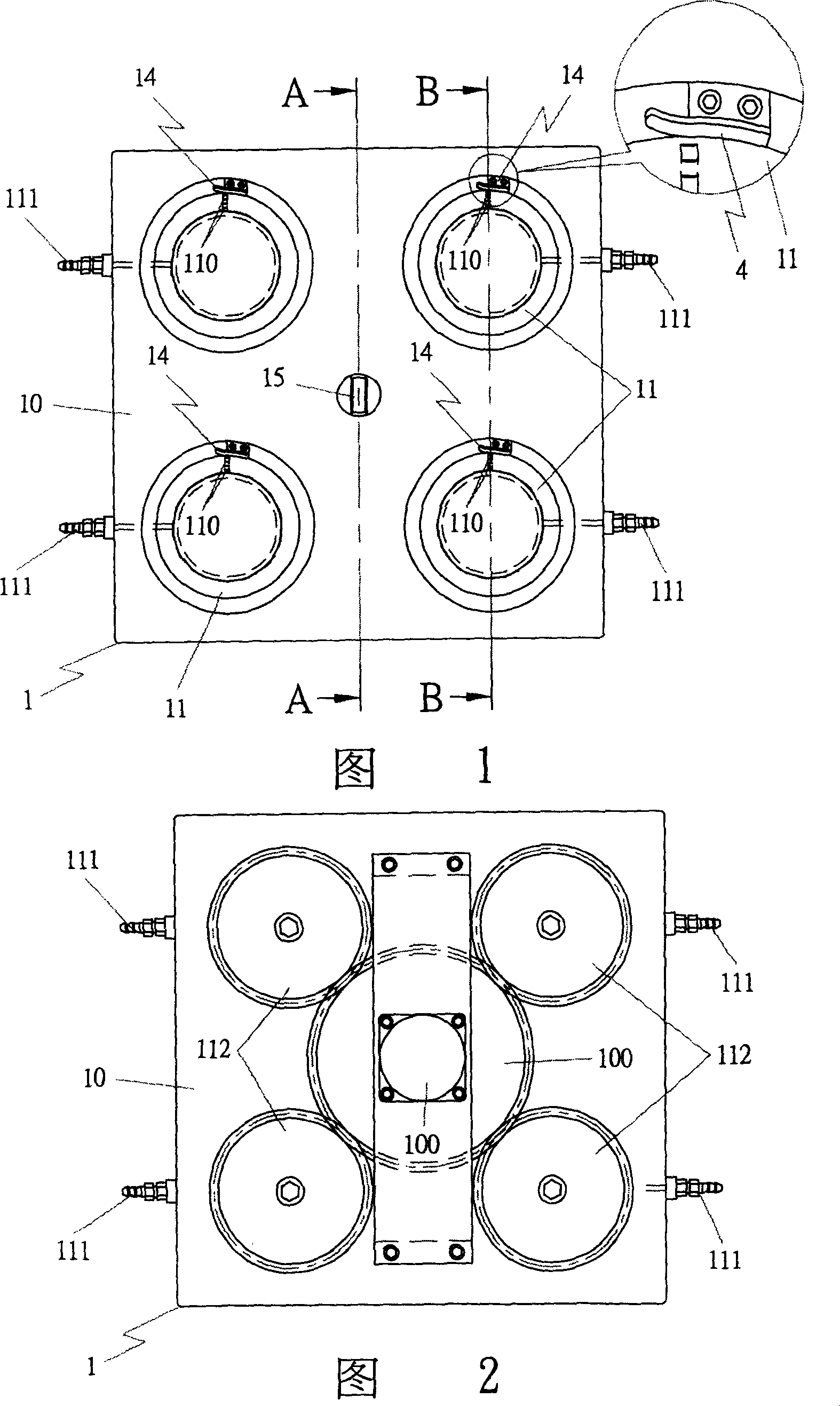

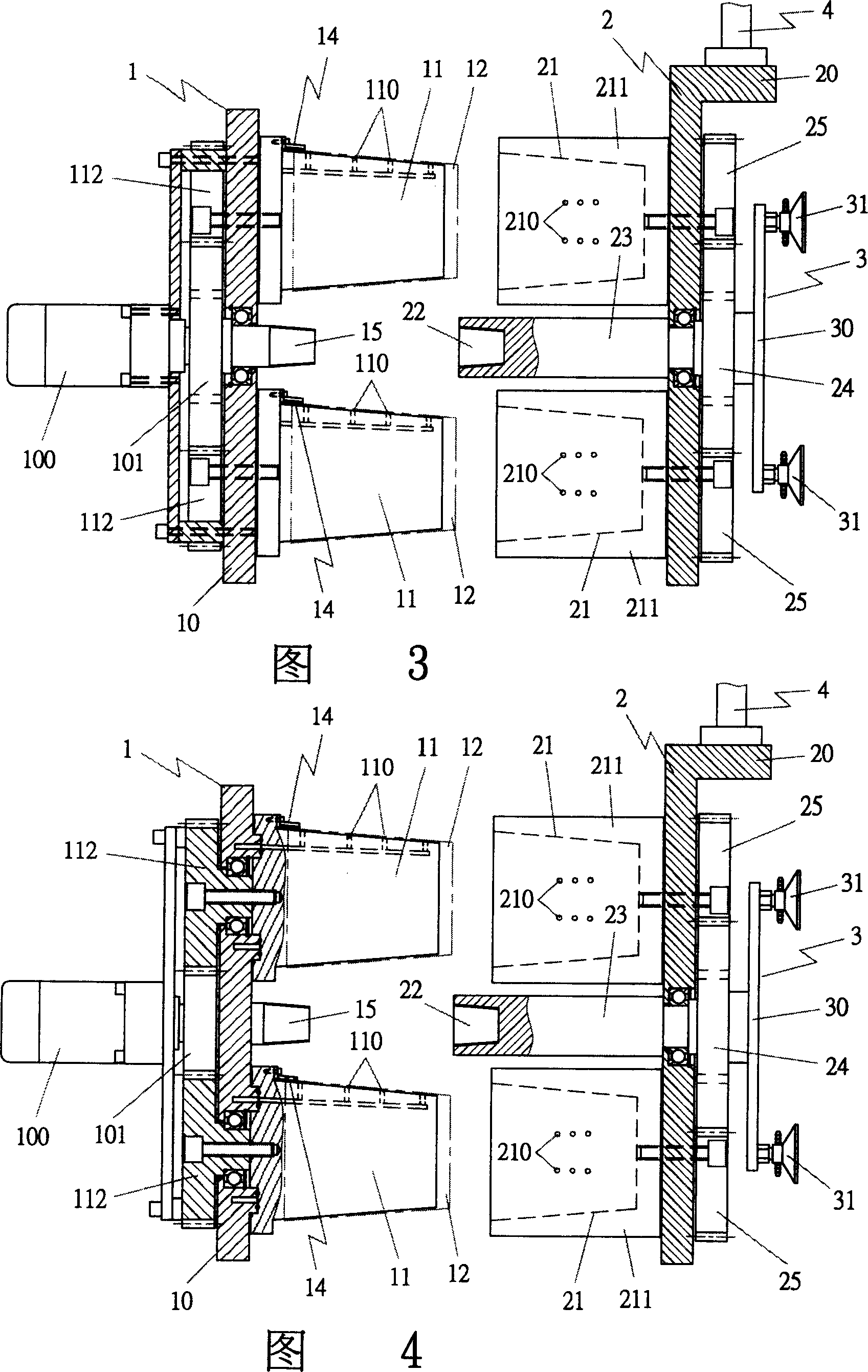

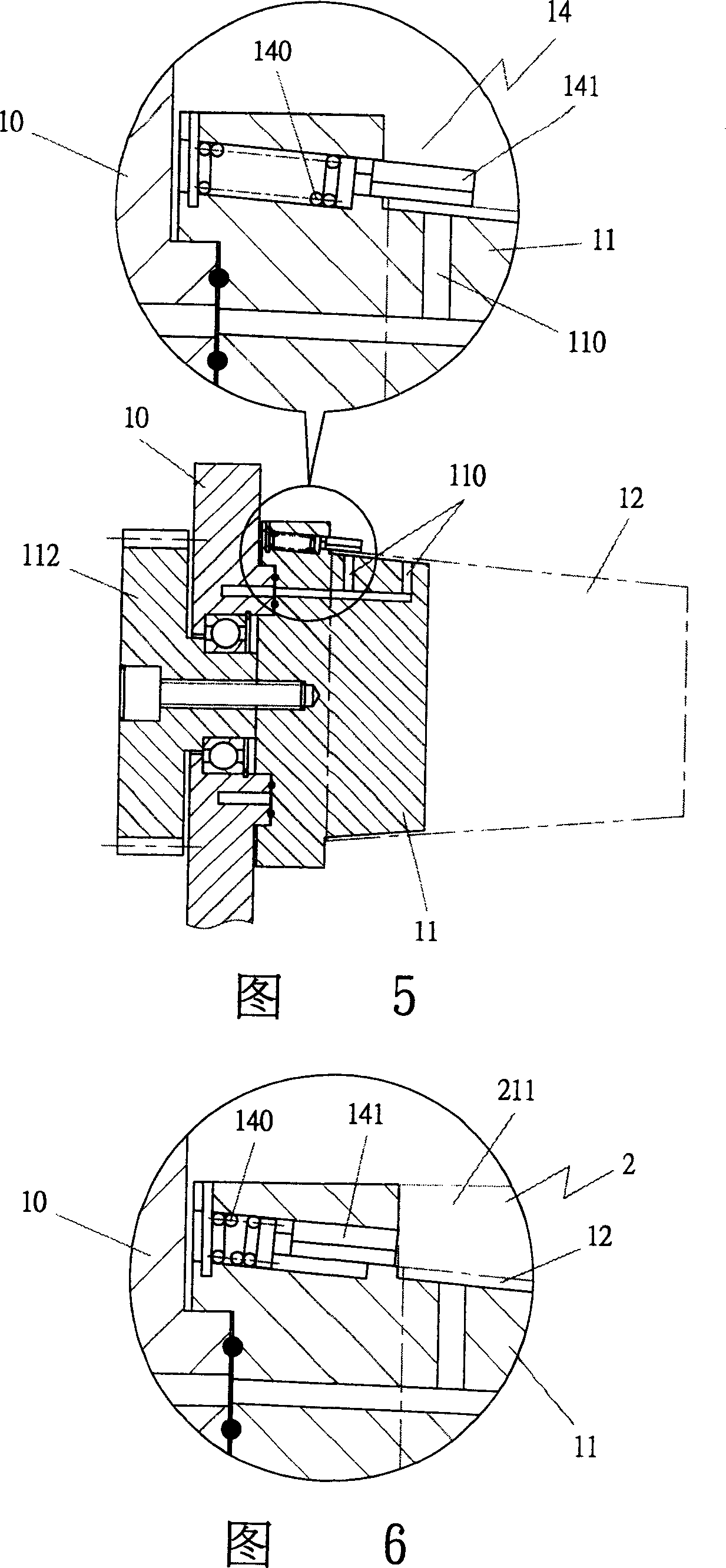

[0046] In order to enable the examiner to fully understand the industrial application value of the present invention, the accompanying drawings are hereby explained as follows:

[0047] As shown in Figures 1-17F, it is the label roll / setting mechanism of the present invention, which includes:

[0048] The labeling mechanism 1, the labeling mechanism 1 is provided with a base 10, and the base 10 is provided with a group; or more than one set of labeling mold bases 11, the number and shape of the labeling mold bases 11 are matched with the number and shape of the mold grooves of the forming mold In order to be suitable for the taking / placement of ring-shaped labels, and each label mold base 11 is provided with a plurality of suction holes 110 through which the suction holes 110 are provided with suction pipes 111, and the suction pipes 111 are externally connected to the pumping The air device (as shown in FIG. 3 and FIG. 4 ) makes the aforementioned air suction hole 110 produce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com