3 pieces per set tearing flip type wine bottle cap

A flip-top, wine-bottle-cap technology, which is applied in the directions of tightly capping containers, capping, and closing parts with lids, can solve the problems of complex internal structure, difficult dust removal process, and complex assembly process, and achieves a reasonable overall structure design, Increase the cultural connotation of wine and improve the effect of artistic taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

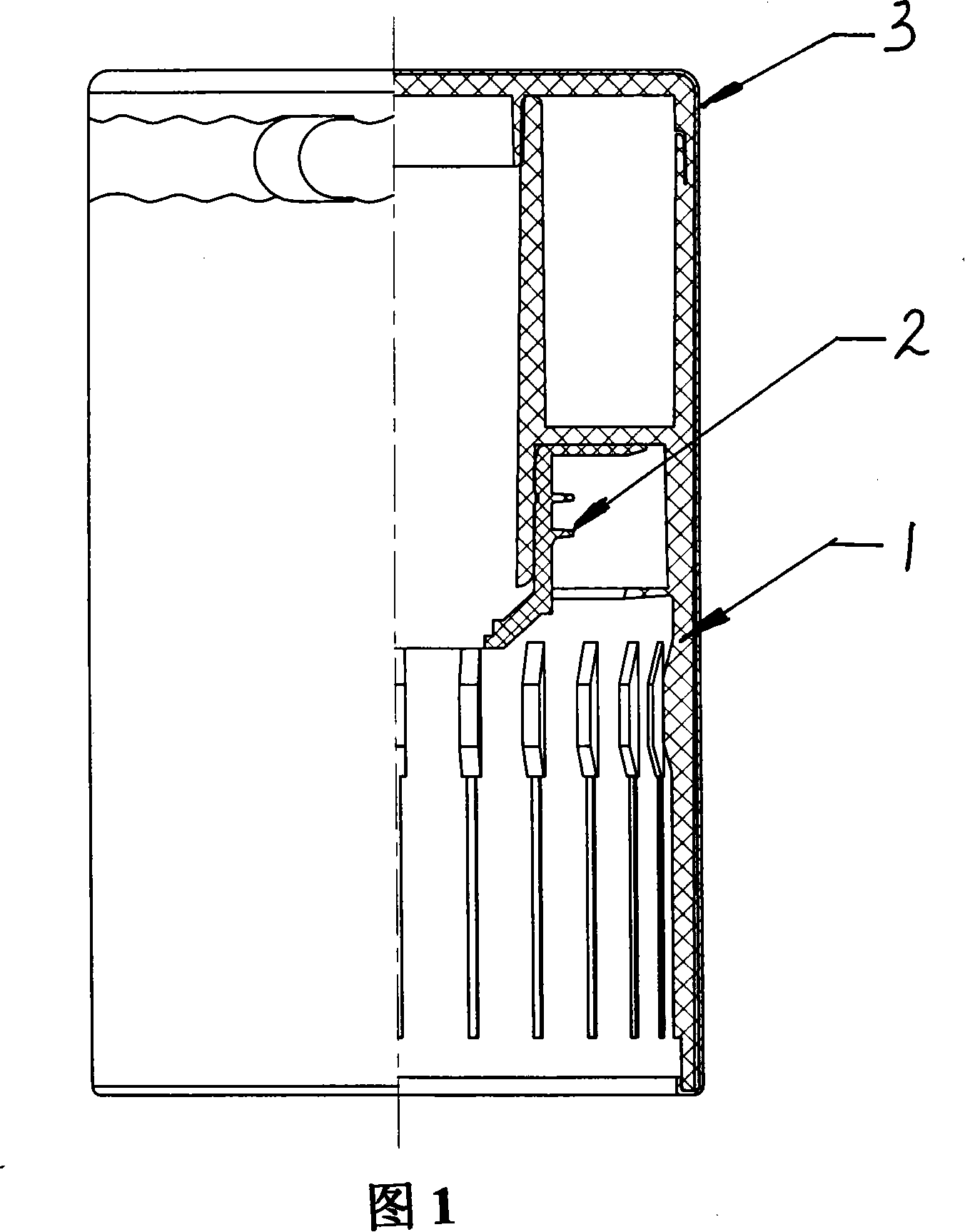

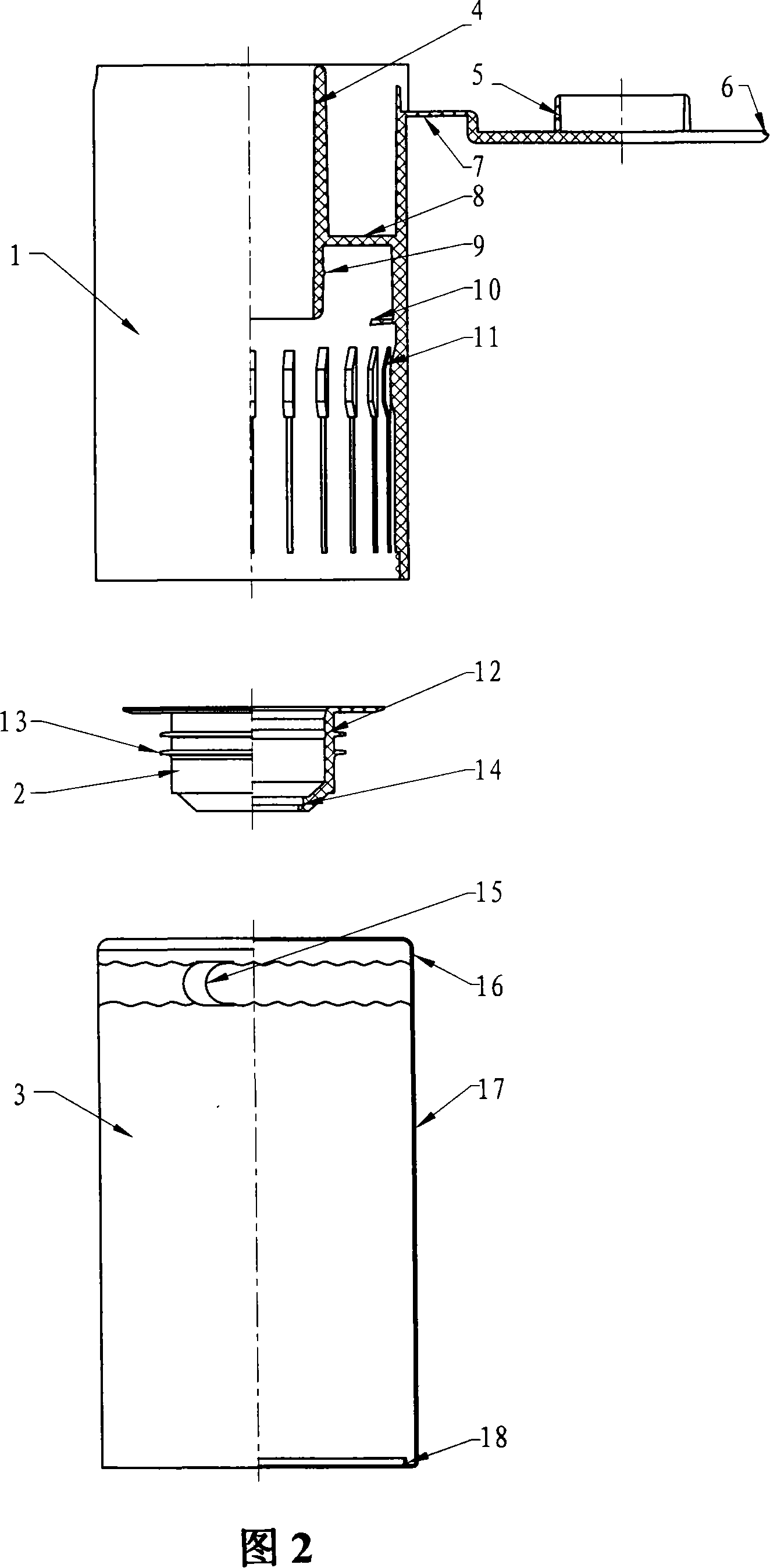

[0015] The present invention is mainly composed of an outer jacket 3, a fixed sleeve 1 placed in the outer jacket 3, an inner plug 2 placed in the fixed sleeve 1, etc.; the outer jacket 3 is provided with a tear opening 15, and the outer jacket 3 is divided into an upper body 16 and a lower body 17. The bottom of the jacket 3 is provided with a flanging 18; the upper part of the fixed sleeve 1 is provided with a flip cover 6 with a connecting piece 7, and the inside is provided with a positioning piece 8 with an outlet ring 4 and a sealing ring 9, and a thrust to prevent the bottle from falling off. Ring 10, anti-rotation ribs 11 to prevent spinning on the bottle; flip cover 6 is provided with a wine sealing ring 5 that cooperates with the outlet ring 4; inner plug 2 is provided with a stopper 14, and a sealing sheet 13 that cooperates with the inner mouth of the wine bottle , the sealing rib 12 that cooperates with the sealing ring 9.

[0016] The upper body 16 and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com