Rotation lifting mechanism in steel tube quenching device and steel tube quenching method

A technology of rotating lifting and quenching devices, applied in the direction of quenching devices, furnaces, heat treatment equipment, etc., can solve problems such as the need to improve safety and reliability, not suitable for quenching process and overall equipment requirements, and defects in the automatic lifting and accurate positioning of steel pipes, etc., to achieve Superior technical effects and comprehensive functions, compaction and discharge technical effects and comprehensive functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

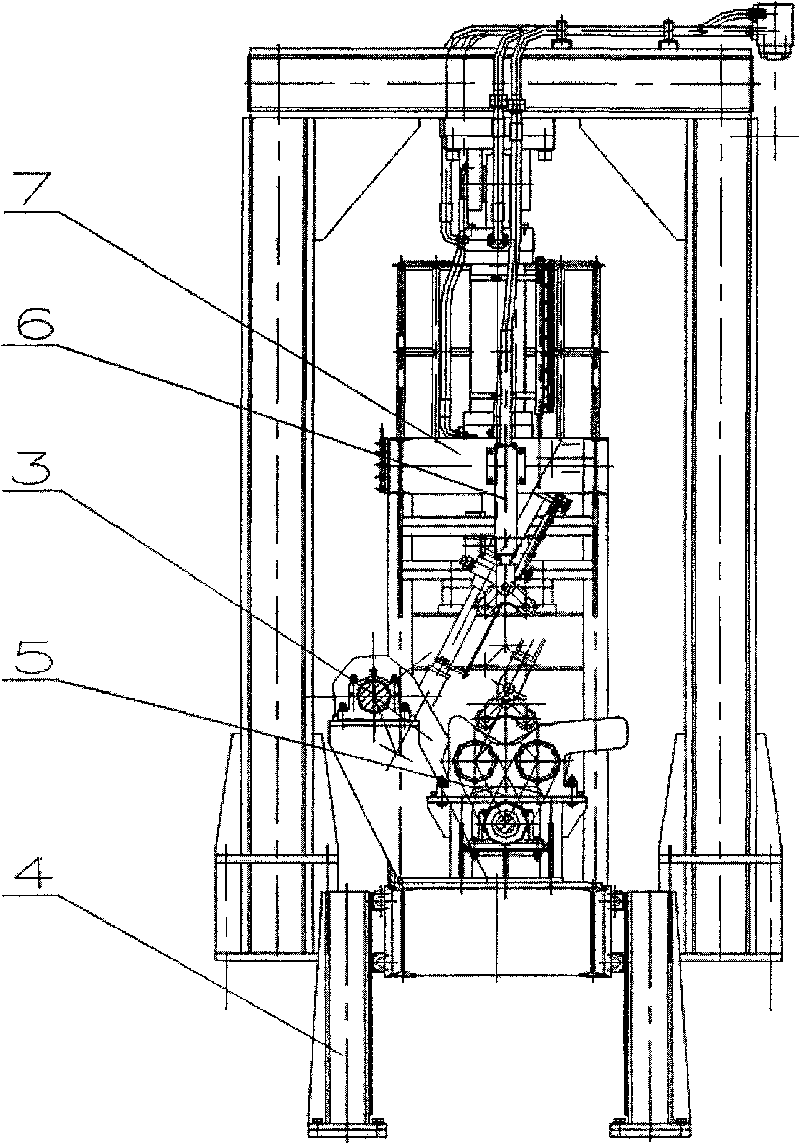

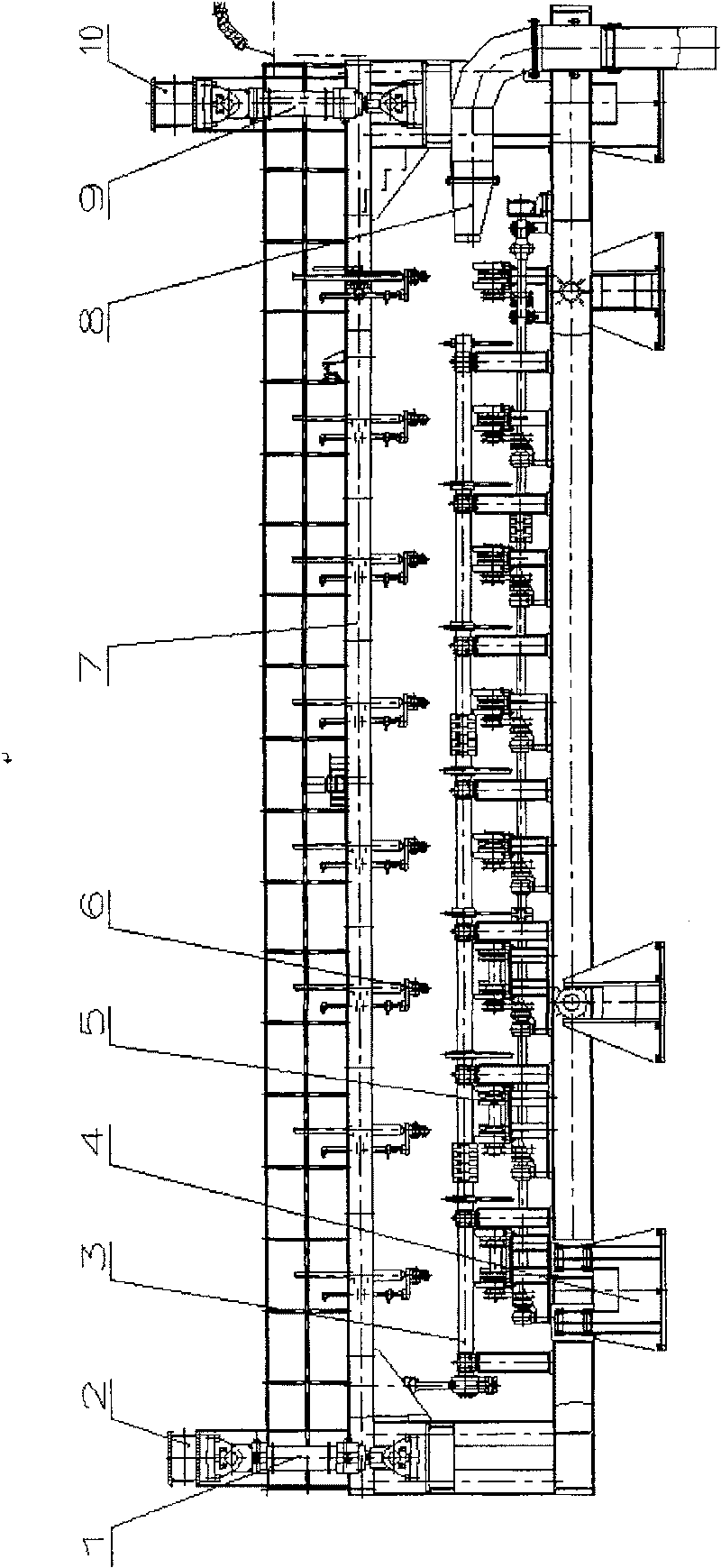

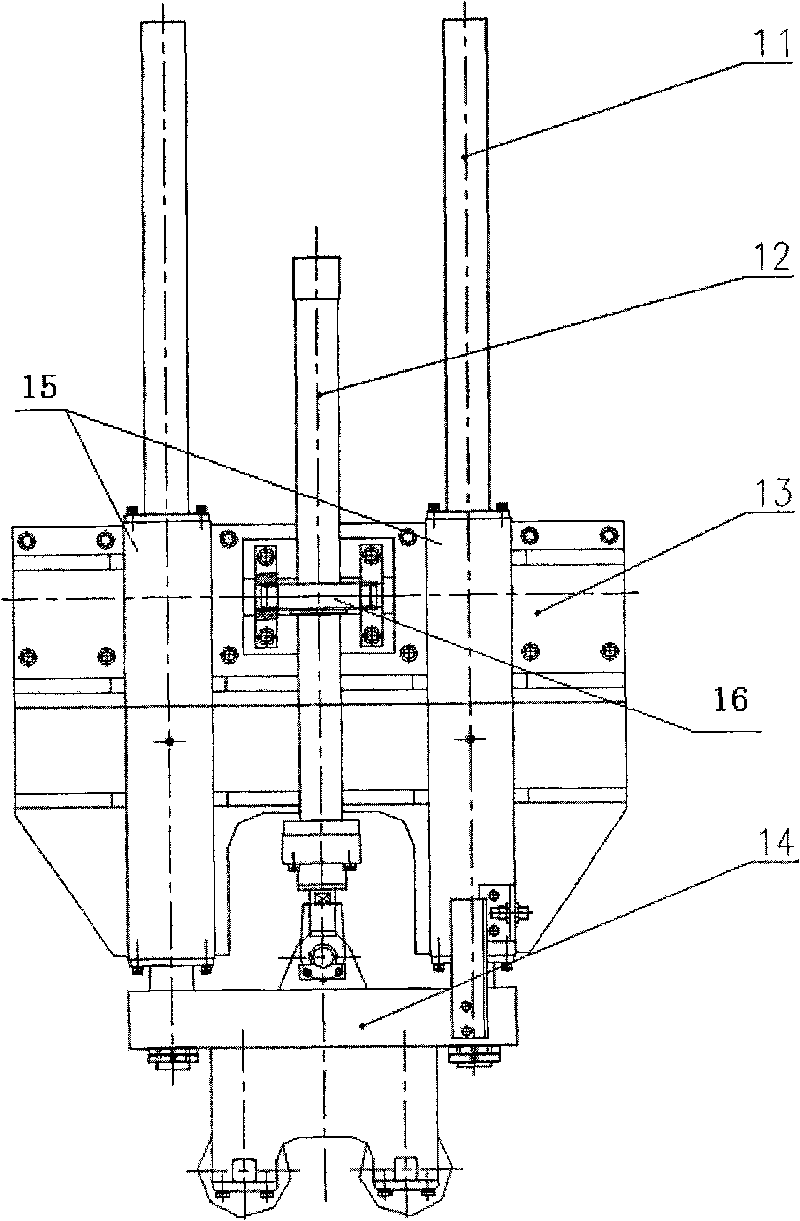

[0016] The equipment structure of the present invention adopts double oil cylinders as power to drive the frame beam to move up and down, from this embodiment figure 1 with figure 2 It can be seen that the rotary lifting mechanism at least includes a left lifting cylinder 1, a left supporting beam 2, a right lifting cylinder 9, a right supporting beam 10, a frame beam 7, a blanking flap 3, a guide bracket 4, a rotating support 5, and a pressing device 6. Internal spray nozzle 8. The anchor bolts at the bottom of the left support beam 2 and the right support beam 10 are fixed to the foundation; the upper part of the left lift cylinder 1 is hinged with the left support beam 2, and the lower part is hinged with the frame beam 7; the upper part of the right lift cylinder 9 is hinged with the right support beam 2, and the lower part It is hinged with the frame beam 7; the left side of the frame beam 7 is hinged with the left lifting cylinder 1, and the right side is hinged with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com