Bearing strength experiment instrument of high-temperature high-pressure mud cake plugging

A high-temperature, high-pressure, compressive-strength technology, applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of inability to measure in real time and record data in real time, and achieve the effect of high pressure and temperature range and wide permeability range

Active Publication Date: 2010-11-10

CHINA PETROLEUM & CHEM CORP +1

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

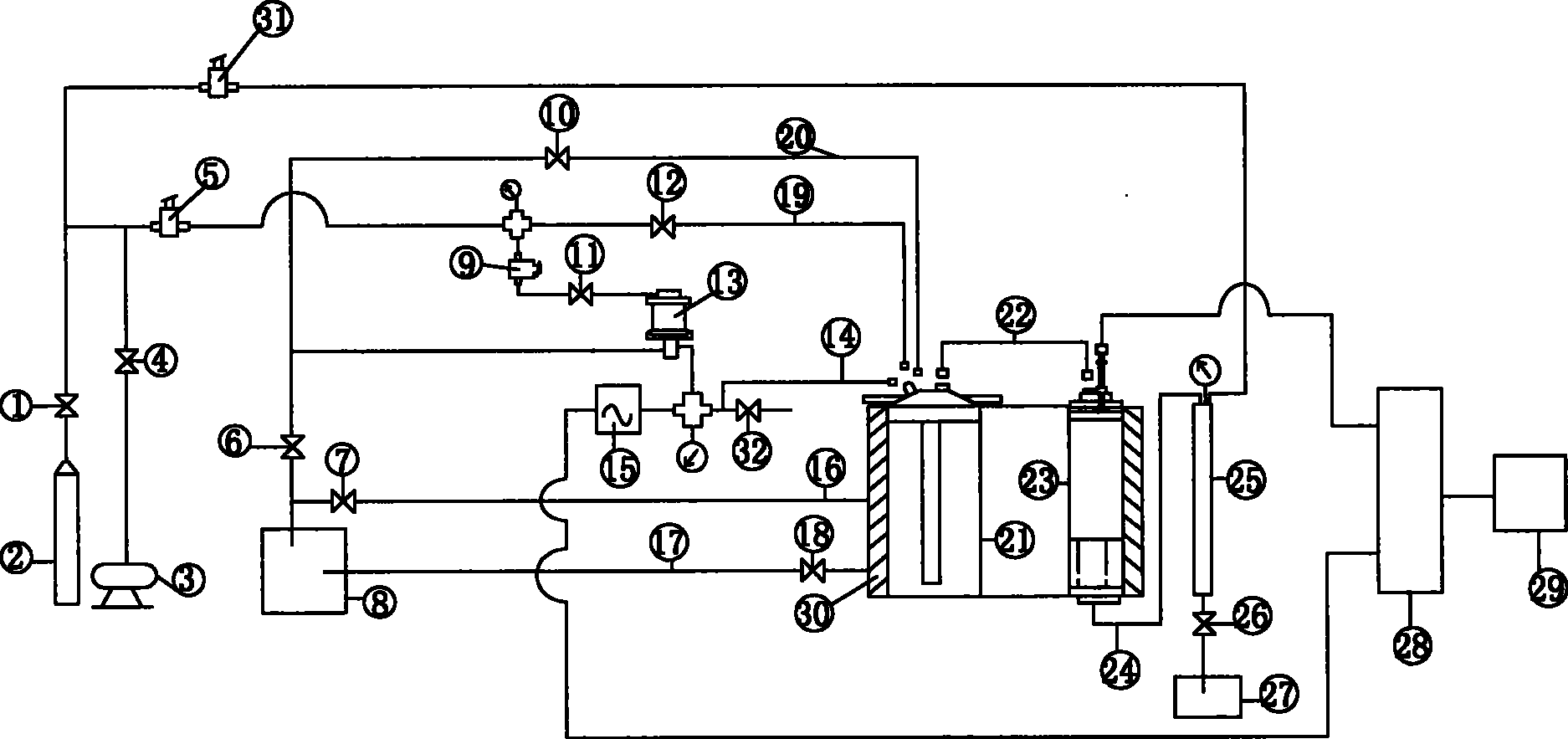

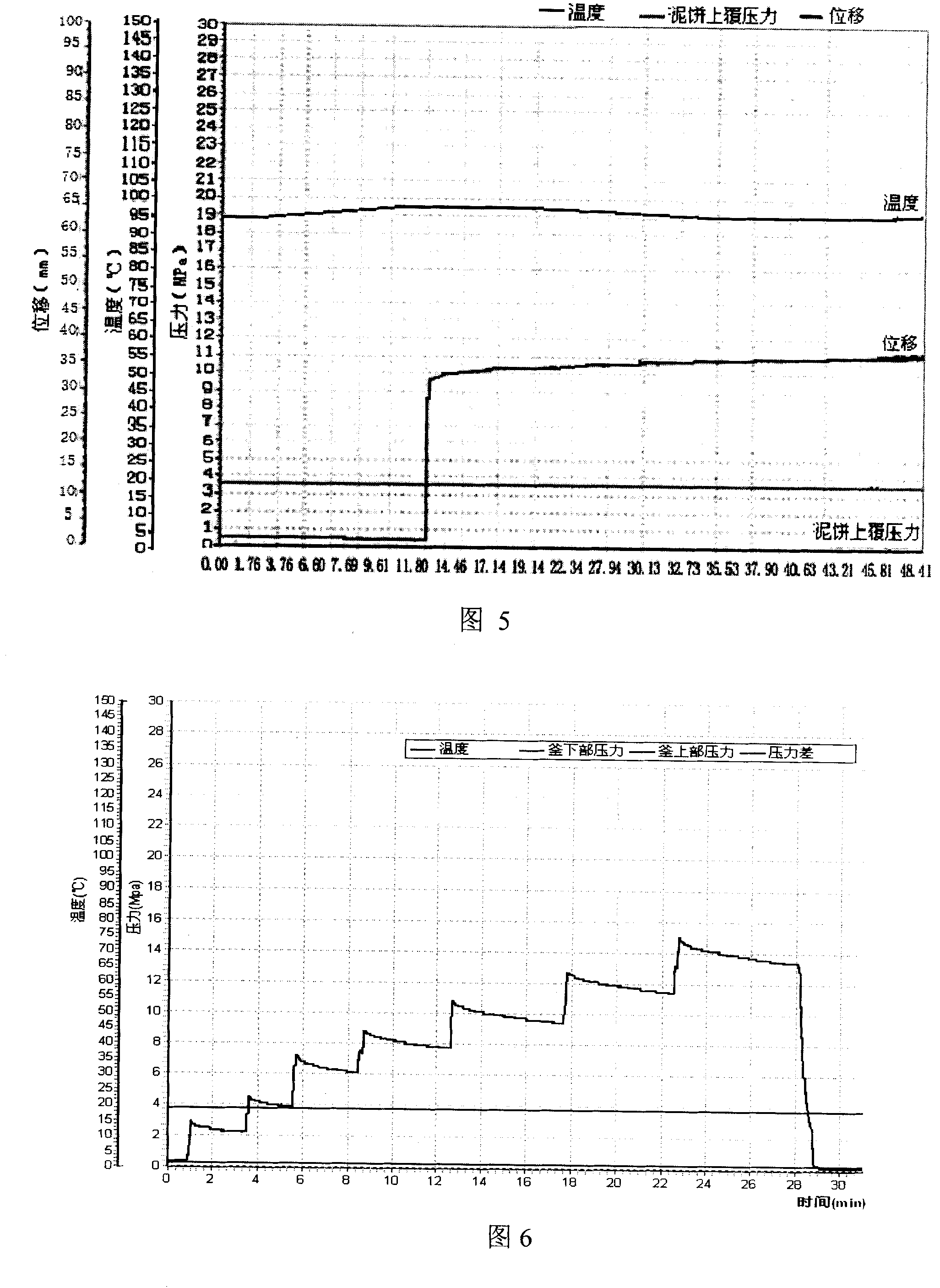

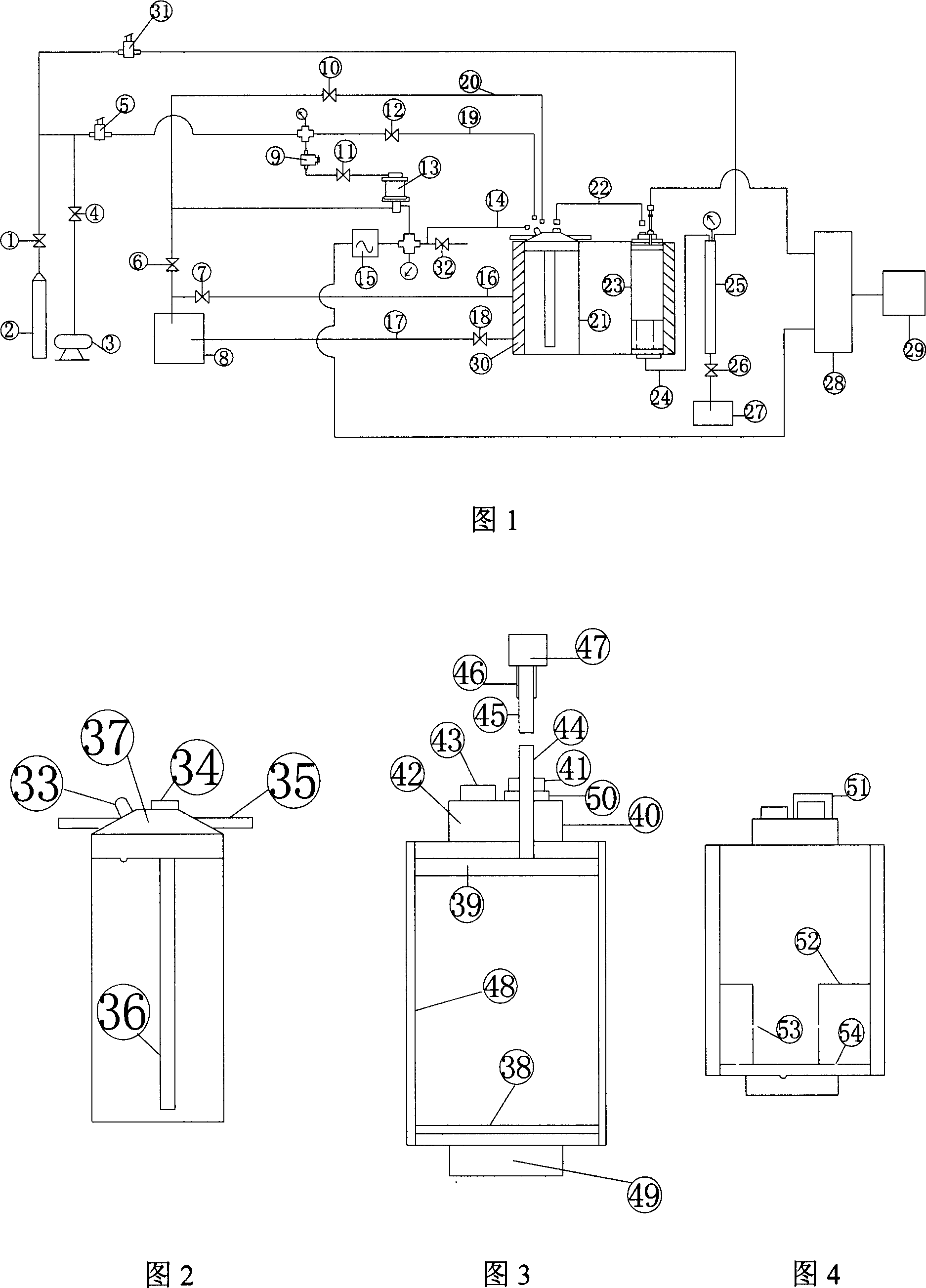

The present invention proposes a high temperature and high pressure mud cake plugging pressure bearing strength tester in order to solve the shortcomings of the existing measuring instruments in the field that they cannot simulate the downhole conditions under high temperature and high pressure for real-time measurement and real-time data recording. It can simulate the downhole static conditions and test the mud filtrate intrusion into the simulated rock bed depth, mud cake bearing strength, different size fracture plugging and bearing strength change experiments during the drilling process of oil (gas) wells, and realize real-time recording of experimental data

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a tester for the bearing and plugging strength of a mud cake under high temperature and high pressure, which can simulate the static conditions in a well and test the invasion depth of slurry filter liquid, bearing strength of mud cake, plugging and bearing strength against cracks in drilling for oil (gas) wells. The tester essentially comprises a mud-cake performance evaluation and test vessel assembly, a pressure pipe system, a temperature control system, a displacement record system, an automatic cleaning system and a computer data processing system. The tester allows all-sided simulation of the temperature, pressure and stratum features (seepage) under a well, determination the plugging and bearing strength of mud cakes, optimization of drilling fluid, rapid andsafe drilling, therefore the tester is of a very wide application prospect.

Description

High temperature and high pressure mud cake plugging pressure strength tester technical field The invention relates to a petroleum drilling scientific research experiment instrument in the field of petroleum engineering exploration and development, a high-temperature and high-pressure mud cake plugging pressure-bearing strength test instrument, more specifically, relates to testing oil (gas) well drilling in a laboratory environment by simulating static downhole conditions During the process, the drilling fluid filtrate invades the sandstone depth, mud cake bearing strength, fracture plugging and bearing strength experimental equipment. Background technique At present, there are few indoor test methods and instruments for mud cake properties, mud cake crack plugging and pressure bearing under high temperature and high pressure conditions, and the measurement instruments have single functions. There is no integrated equipment that can simulate formation conditions to measure...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N33/00

Inventor 宋明全江山红何汉平肖超王治法谭春勤

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com