Pneumatic tire

A technology of pneumatic tires and tires, which is applied in the direction of heavy tires, tire parts, tire treads/tread patterns, etc., can solve the problems of reducing the rigidity of the grounding part, increasing the volume of the tread rubber, and poor surface, etc., to achieve the suppression of grounding Partial deformation, ensure the effect of heat dissipation and drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

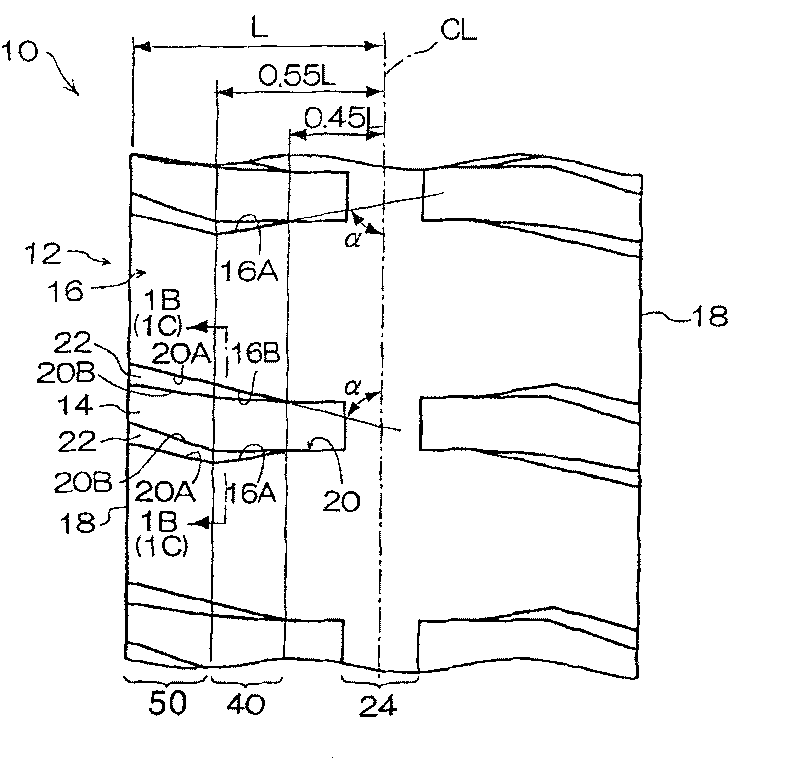

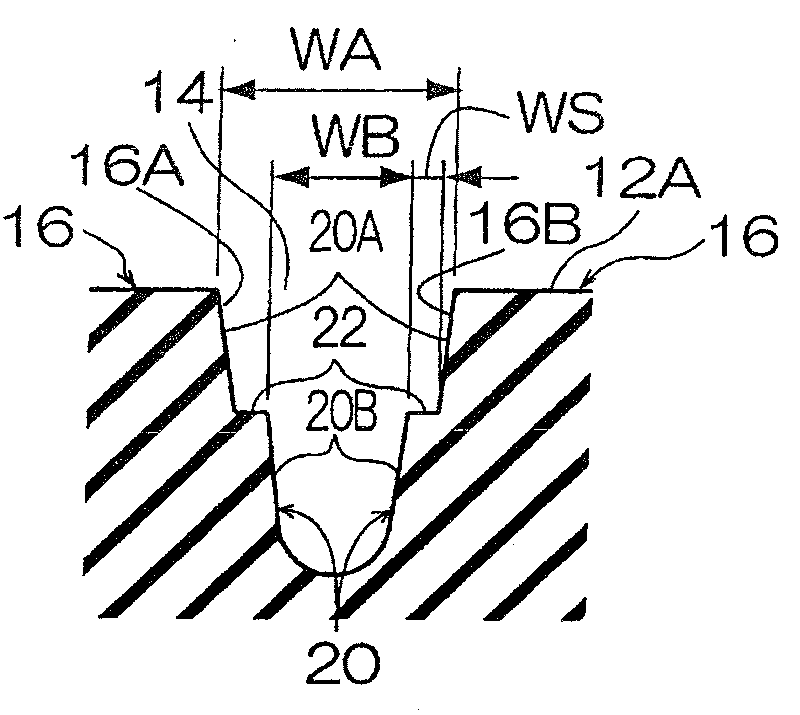

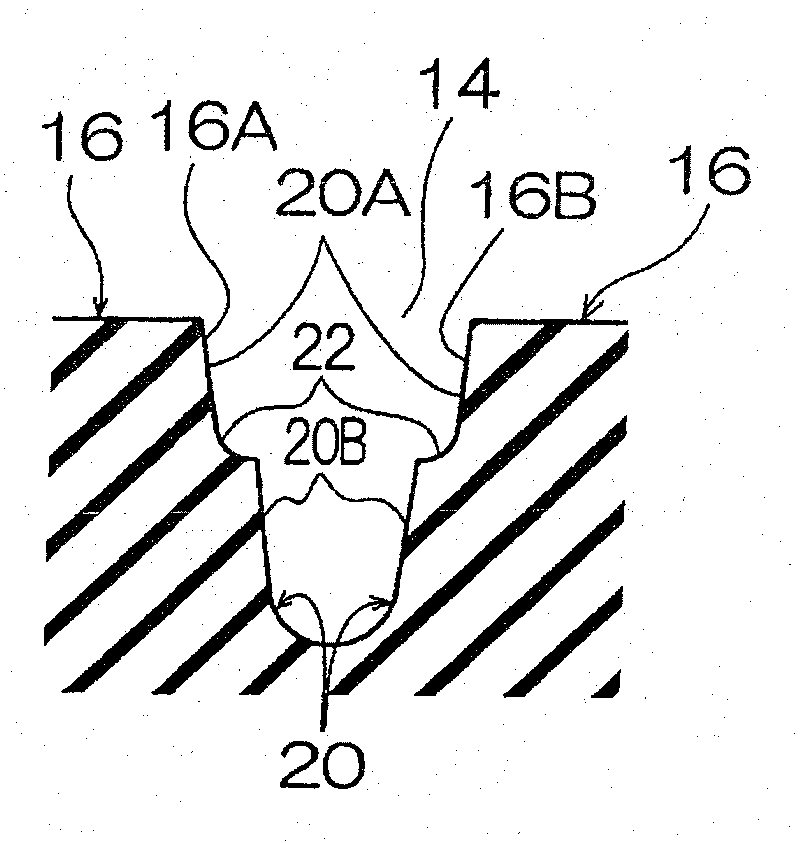

[0058] exist Figure 1A Among them, the pneumatic tire 10 of the present embodiment has, on the tread 12, lug grooves 14 arranged in a direction intersecting with the tire circumferential direction and land portions 16 defined by the lug grooves 14. The center ribs 24 are arranged in the tire circumferential direction and are connected to the land portion 16 on the tire equatorial plane CL. The lug groove 14 terminates on the tire equatorial plane CL side without penetrating the center rib 24 and is formed on the tire axially outer side at least to the ground contact end 18 . Here, small grooves connecting the lug grooves 14 across the tire equatorial plane CL may be arranged in the center rib 24 .

[0059] On the pneumatic tire 10, when the distance from the ground contact end 18 to the tire equatorial plane CL is L when the pneumatic tire 10 is installed on a normal rim to fill it with normal internal pressure and make it bear the normal load, In the area 40 where the dista...

no. 2 Embodiment approach

[0091] In the pneumatic tire 30 of the present embodiment, in the pneumatic tire 10 of the first embodiment, the tread 12 is formed in a region of 0.55L to 0.70L away from the tire equatorial plane CL toward the outside in the tire axial direction. Circumferential grooves 32 extending in the tire circumferential direction.

[0092] Here, the reason why the position where the circumferential direction groove 32 is formed is set in this way is because: if it is less than 0.55L, the rigidity in the vicinity of the circumferential direction groove 32 decreases, thereby reducing the wear resistance; if it is greater than 0.70L, the circumferential direction The effect of the groove 32 is hardly transmitted to the 1 / 4 point, so the influence of the angle of the lug groove near the ground contact end 18 on the effect of suppressing uneven wear cannot be ruled out.

[0093] In addition, considering the influence on cracks at the bottom of the groove, it is preferable that the groove w...

Embodiment 1

[0103] The pneumatic tire of Example 1 has such Figure 1A , Figure 1B In the shown tread 12 , the inclination angle α of the side groove wall 20A of the tread contact surface is 70° to 85°, and the groove depth of the lug groove 14 is 90 mm. The width WS of the step portion 22 at the ground contact end 18 is 15 mm, and the width gradually decreases toward the tire equatorial plane CL. In addition, the groove width of the lug groove 14 in the vicinity of the tread contact surface 12A of the ground contact end 18 is 80 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com