Display device, its manufacturing method, and display medium

A display device and display unit technology, applied in optics, instrumentation, nonlinear optics, etc., can solve problems that hinder power consumption reduction, microcapsules reduce image quality, and diffuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

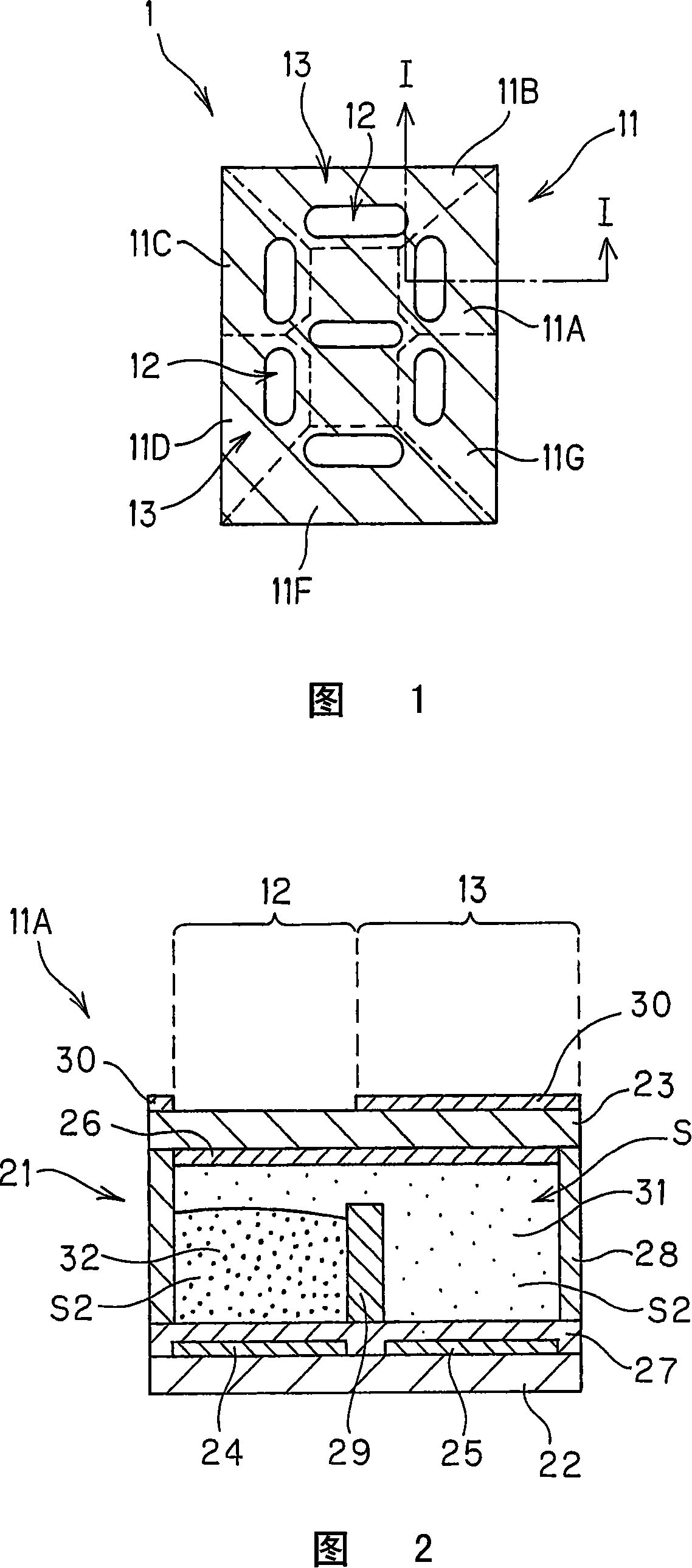

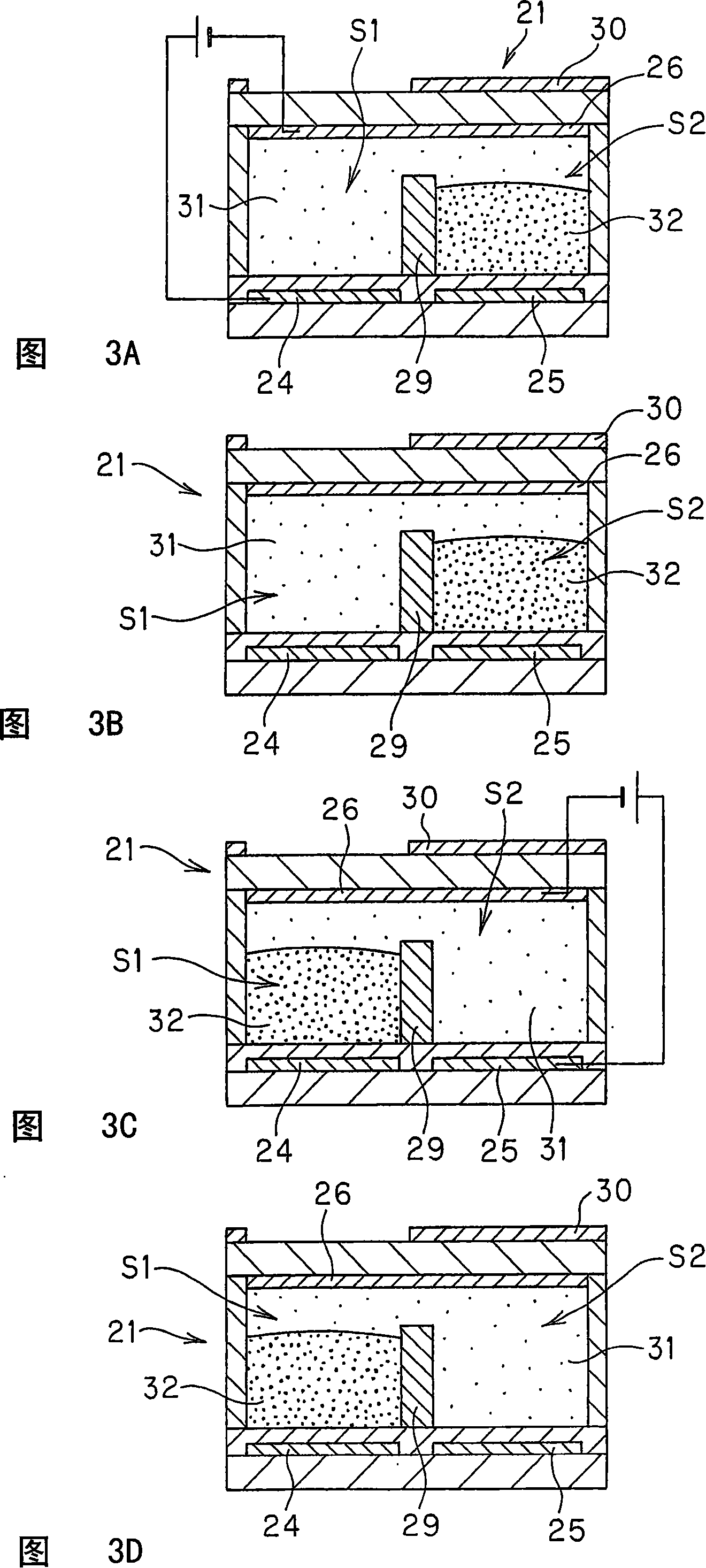

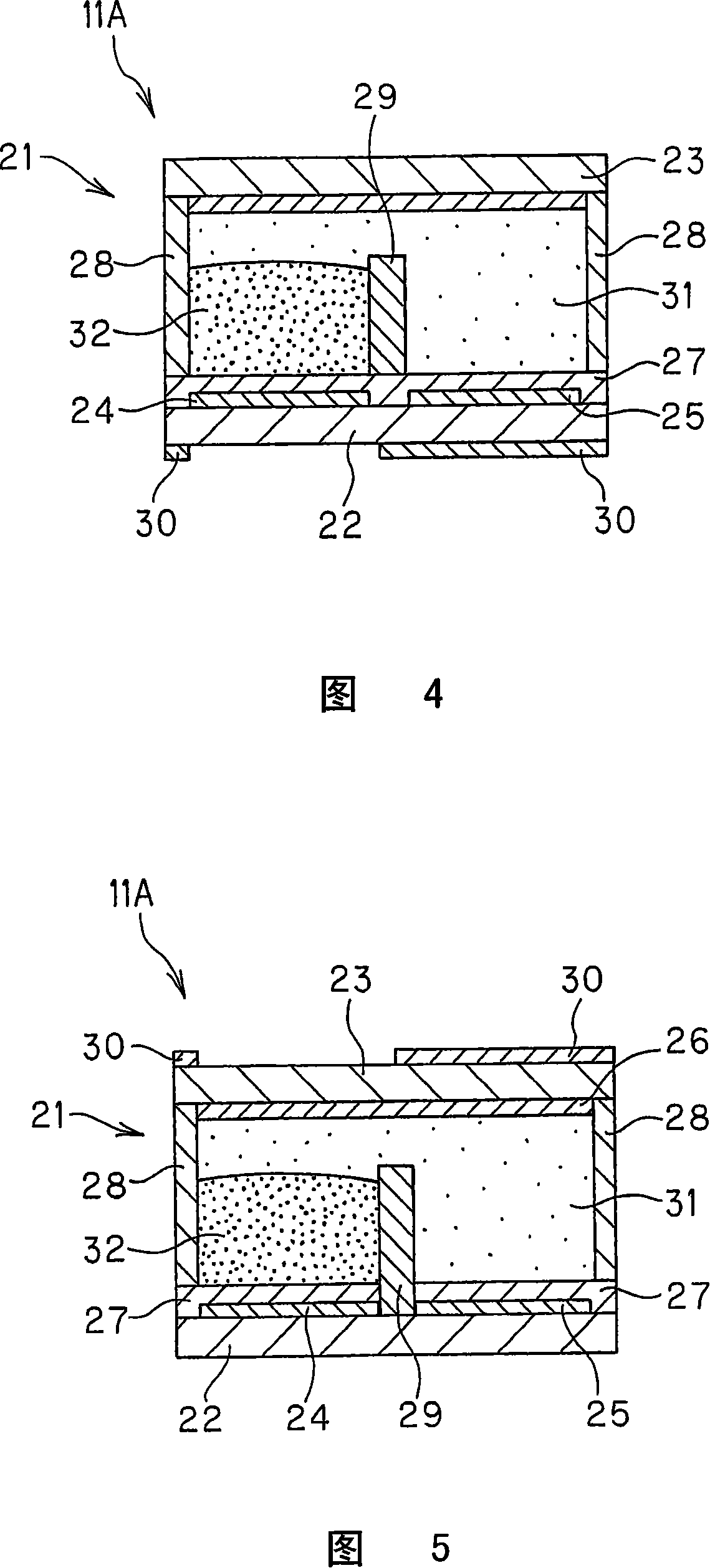

[0128] 2 is an enlarged longitudinal sectional view showing Embodiment 1 of the display device of the present invention, showing the configuration of one display unit along the line I-I in FIG. 1 . As shown in FIG. 2 , the display unit 11A encloses a conductive or polar first liquid 31 and a hydrophobic second liquid 32 in a container 21 . In addition, although the structure of the display unit 11A is shown in FIG. 2, the structure of each other display unit is the same.

[0129] The container 21 is provided with one set of base materials 22, 23; One base material 22 includes a first A electrode 24 and a first B electrode 25 arranged electrically independently from each other on the side of the liquid filling space S, and an insulating layer 27 covering them. On the insulating layer 27 , an intermediate partition wall 29 is arranged so as to be located at a boundary portion between the first A electrode 24 and the first B electrode 25 . In addition, the other base material 2...

Embodiment approach 2

[0149] FIG. 6 is a view corresponding to FIG. 2 showing Embodiment 2 of the display device of the present invention, and shows the configuration of one display unit. In the form shown in FIG. 6 , a conductive or polar first liquid 31 and a hydrophobic second liquid 32 are enclosed in a container 41 of a display unit 11A.

[0150] The container 41 is provided with one set of base materials 42, 43; One base material 42 includes, on the side of the liquid filling space S: a first A electrode 44 and a first B electrode 45 arranged electrically independently from each other; and an insulating layer 47 covering both. On the insulating layer 47, an intermediate partition wall 49 is arranged so as to be located at a boundary portion between the first A electrode 44 and the first B electrode 45, and divides the liquid filling space S. As shown in FIG. In addition, the other base material 43 is provided with the second electrode 46 on the side of the liquid filling space S, and the oth...

Embodiment approach 3

[0166] FIG. 9 is a diagram corresponding to FIG. 2 showing Embodiment 3 of the display device of the present invention, showing the configuration of one display unit. In the form shown in FIG. 9 , a conductive or polar first liquid 31 and a hydrophobic second liquid 32 are sealed in the container 61 of the display unit 11A.

[0167] The container 61 is provided with one set of base materials 62, 63; One base material 62 is provided with the 1st A electrode 64 arrange|positioned at the liquid filling space S side, and the insulating layer 67 which covers it. In addition, the other base material 63 includes a first B electrode 65 arranged on the liquid filling space S side and an insulating layer 67 covering it. In addition, a second electrode 66 is provided, arranged substantially parallel to the first A electrode 64 and the first B electrode 65 , and divides the liquid sealing space S. The second electrode 66 has a plurality of through-holes 66a serving as liquid flow paths,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Opening width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com