Reciprocating type bamboo root digging machine

A reciprocating excavator technology, applied in the field of reciprocating bamboo root excavators, can solve the problems of low root removal efficiency, waste of land resources, dense bamboo roots, etc., to improve labor efficiency, reduce labor intensity, and reduce weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with embodiment.

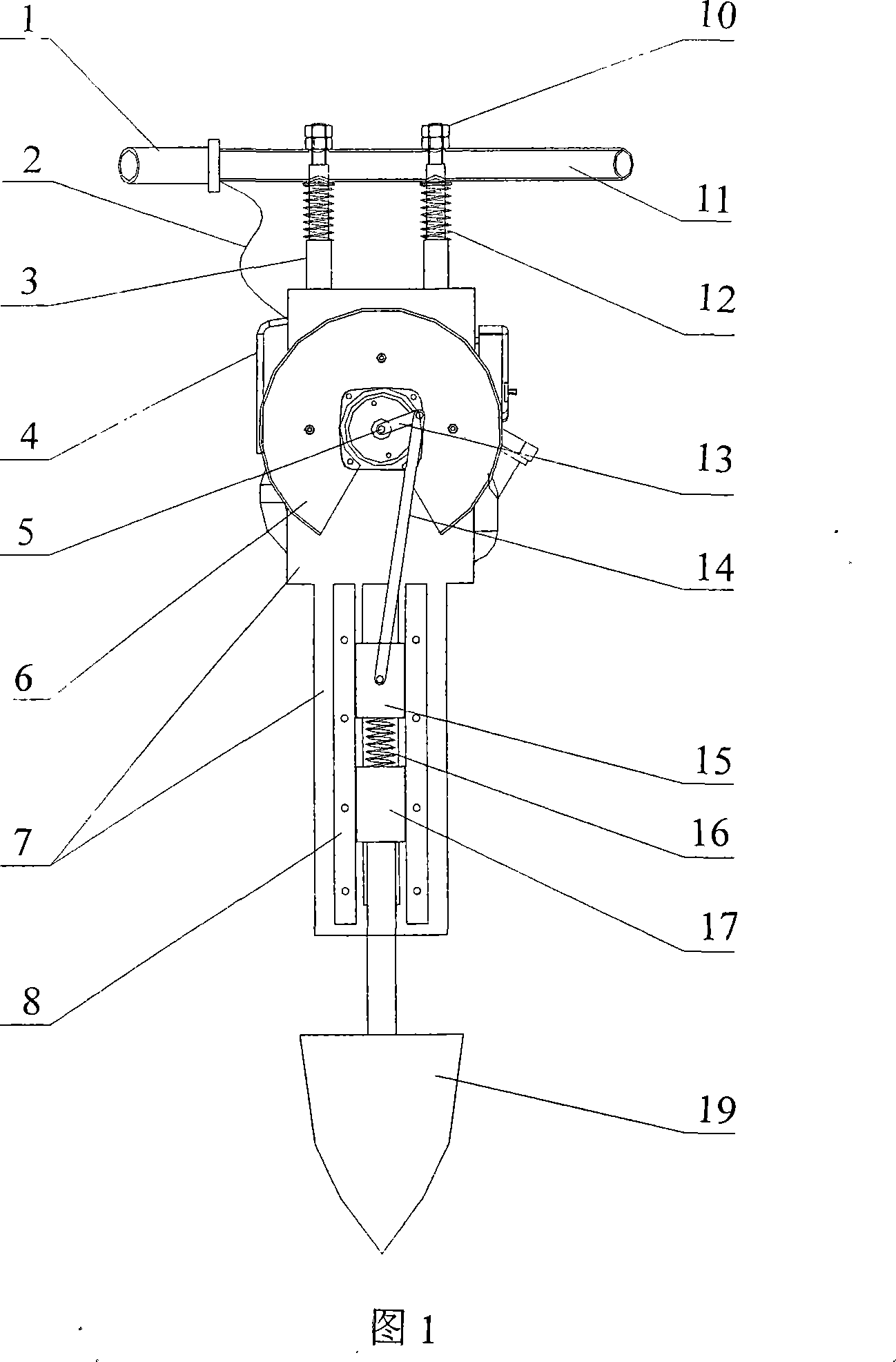

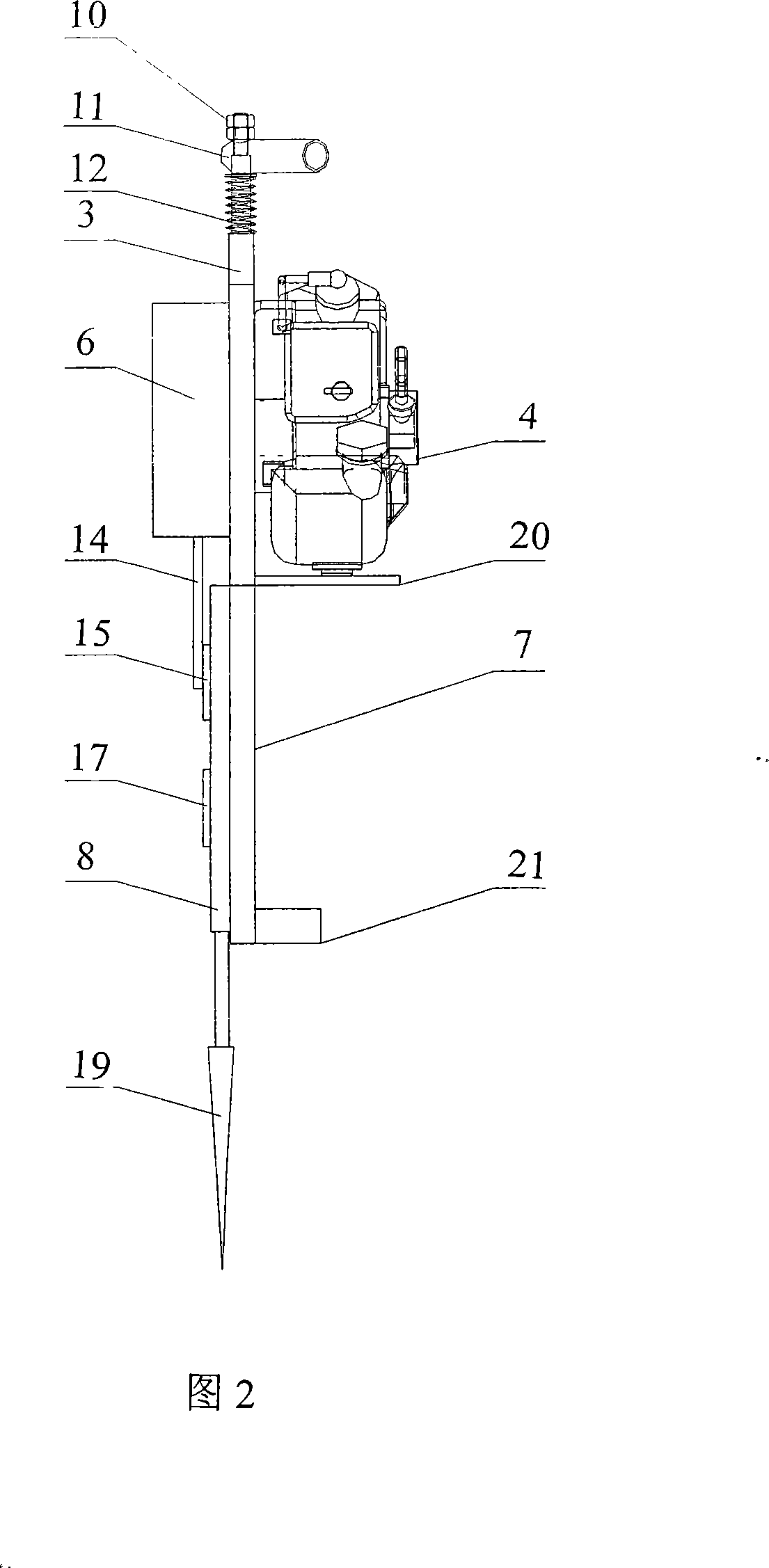

[0012] With reference to accompanying drawing, reciprocating bamboo root excavator comprises support 7, and the gasoline engine 4 with clutch is fixed on the support 7 top, and vertical chute 8 is arranged in the bottom, and two slide blocks 15 that can reciprocate up and down are placed in the chute 8, 17, the two slide blocks are connected by a damping spring 16. In the illustrated example, the chute 8 and the gasoline engine 4 with the clutch are respectively fixed on the positive and negative sides of the support 7. Handle 11 is enclosed within on the connecting rod 3 of support 7 tops, and connecting rod 3 tops are threaded, and spring 12 is housed in the middle part, and handle is pressed on the spring, and is fixed by nut 10. One end of handle 11 is covered with throttle and adjusts hand 1, which can drive throttle line 2 to increase or reduce the throttle of the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com