Spacing mechanical arm modularization joint

A technology of modular joints and space manipulators, used in manipulators, manufacturing tools, joints, etc., can solve the problems of large output torque per unit mass, inability to meet low power consumption, large volume, etc., to achieve large output torque per unit mass, avoid Evaporation and intrusion of external dust, the effect of a high degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

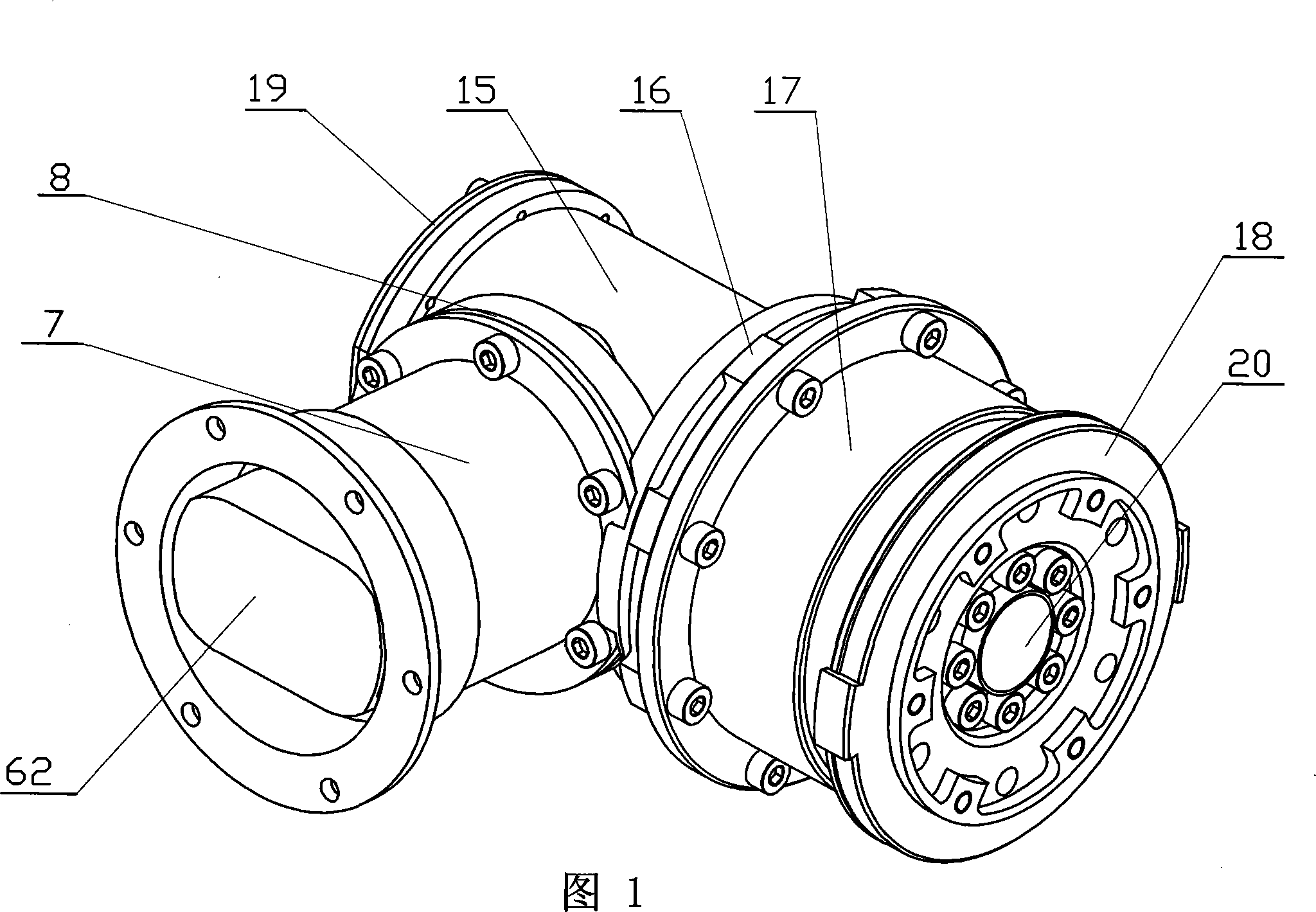

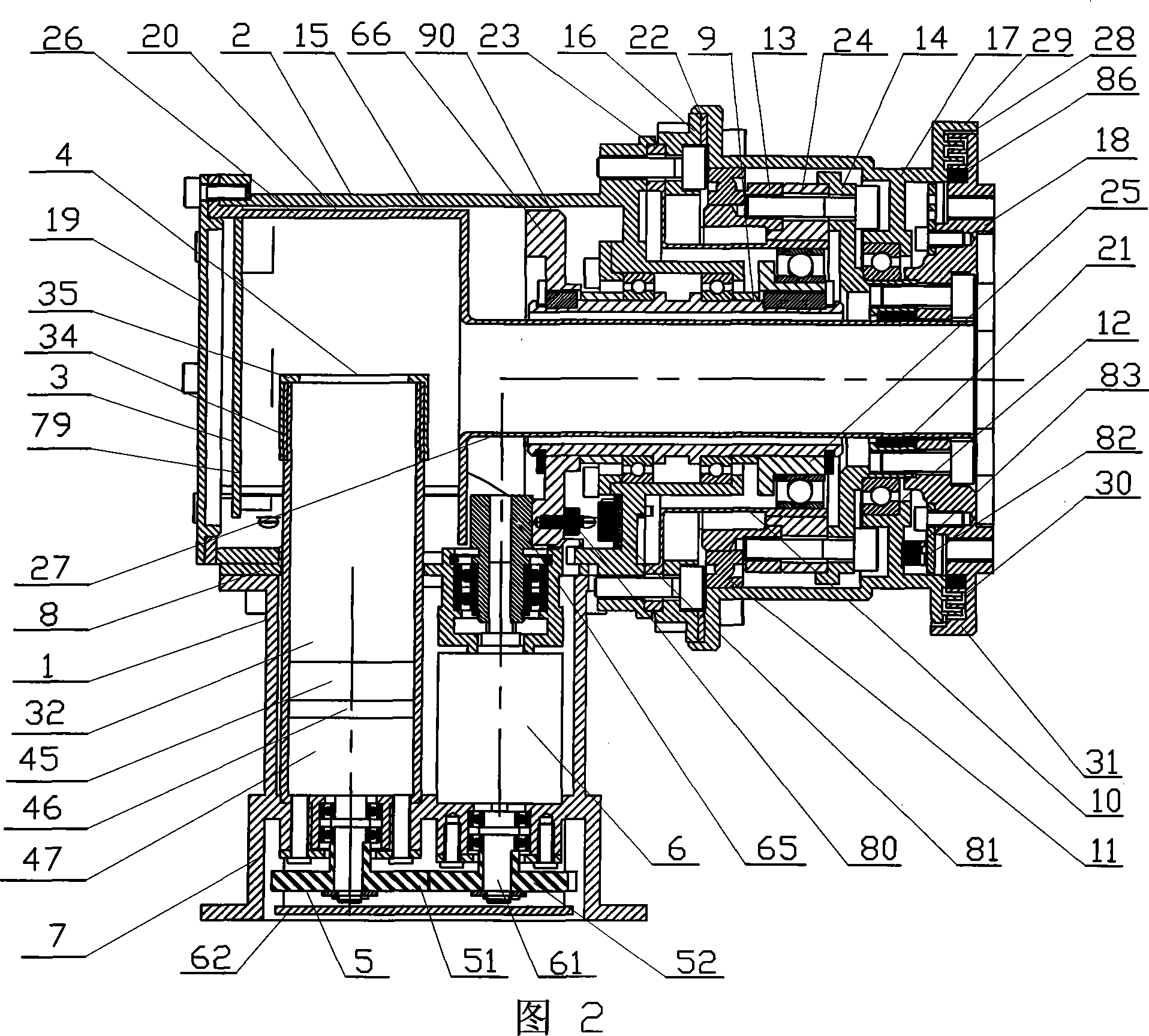

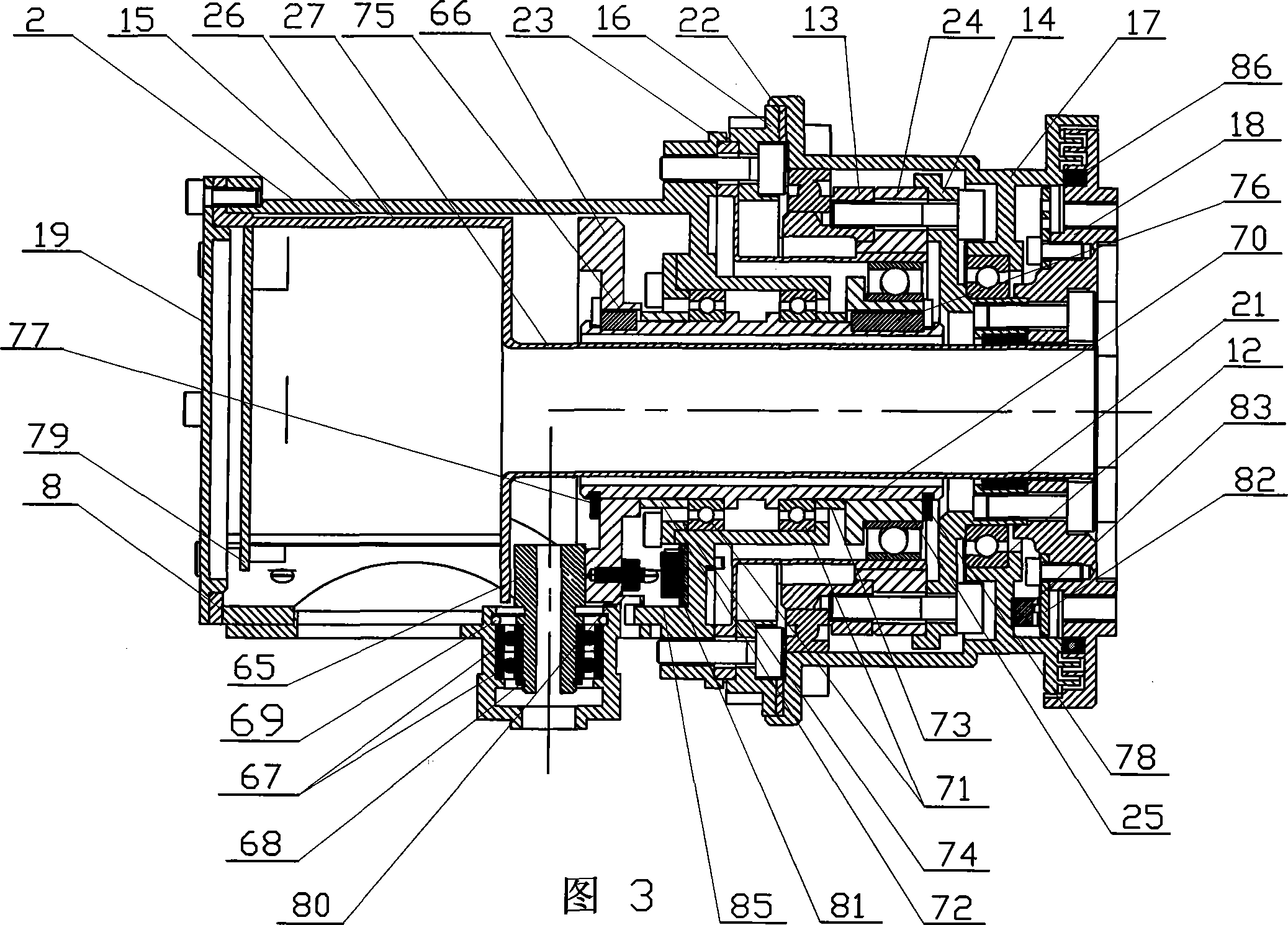

[0007] Specific Embodiment 1: This embodiment is described in conjunction with FIGS. 1 to 17. This embodiment is composed of an input device 1, an output device 2, and an electrical device 3; the input device 1 is composed of a drive device 4, a gear device 5, and a planetary reducer. 6. The input device housing 7 is composed of an adapter flange 8; the output device 2 includes a crown gear device 90, a hollow transmission shaft device 9, a harmonic reducer 10, a large thin-walled bearing 11, a small thin-walled bearing 12, Large thin-wall bearing inner ring support seat 13, small thin-wall bearing inner ring support seat 14, first shell 15, intermediate connecting flange 16, second shell 17, output flange 18, joint rear end cover 19, sleeve 20. Isolation support ring 21 and adjusting gasket 22; the harmonic speed reducer 10 is made up of a flexible spline 23, a rigid spline 24 and a wave generator 25, and the sleeve 20 is made of an integrated big end sleeve 26 and The small ...

specific Embodiment approach 2

[0010] Specific Embodiment 2: This embodiment is described in conjunction with Fig. 2, Fig. 4 and Fig. 6. The drive device 4 of this embodiment consists of a DC brushless motor 32, a friction reverse brake 33, a motor sleeve 34 and a motor sleeve cover 35 Composition; the output end of the DC brushless motor 32 is connected to the input end of the friction type reverse brake 33, the output end of the friction type reverse brake 33 is connected to the input end of the gear device 5, and the DC brushless motor 32 and The friction type reverse brake 33 is contained in the motor sleeve 34, and the rear end of the motor sleeve 34 is threadedly connected with the motor sleeve cover 35. Such setting has the advantages of simple structure and stable and reliable transmission. The friction reverse brake works normally in forward transmission and self-locking in reverse transmission, and does not consume power during braking. Other components and connections are the same as those in the...

specific Embodiment approach 3

[0011]Specific embodiment three: This embodiment is described in conjunction with Fig. 2, Fig. 5 and Fig. 6. The friction reverse brake 33 of this embodiment is composed of a bearing backing plate 36, a pin shaft 37, a bearing 38, a pin shaft plate 39, and a friction plate. 40. Friction plate 2 41, output gear 42, output gear sleeve 43, output gear sleeve bearing 44, brake first housing 45, brake second housing 46 and brake third housing 47; the brake first housing 45, brake The second casing 46 and the third casing 47 of the brake are sequentially connected in series and installed in the motor sleeve 34, the bearing backing plate 36 is installed in the first casing 45 of the brake, and the pin plate 39 is installed in the second casing 46 of the brake and the third casing of the brake. Between 47, three pin holes 48 are evenly distributed along the circumferential direction at corresponding positions on the bearing backing plate 36 and the pin plate 39, and the bearing backing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com