Purchase

A lifting device and fixing device technology, applied in the direction of lifting device, etc., can solve the problems of small structure height, large working stroke, difficult to provide, etc., and achieve the effect of large working stroke, small self-weight, and simple manual operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

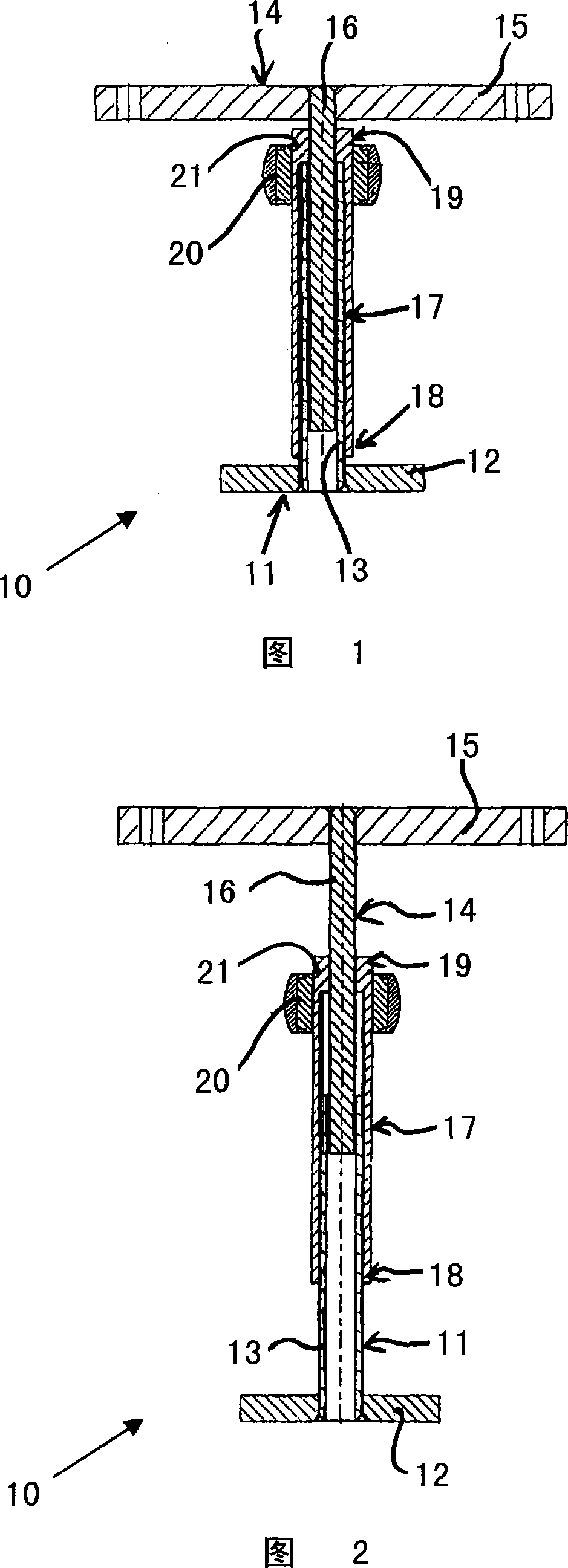

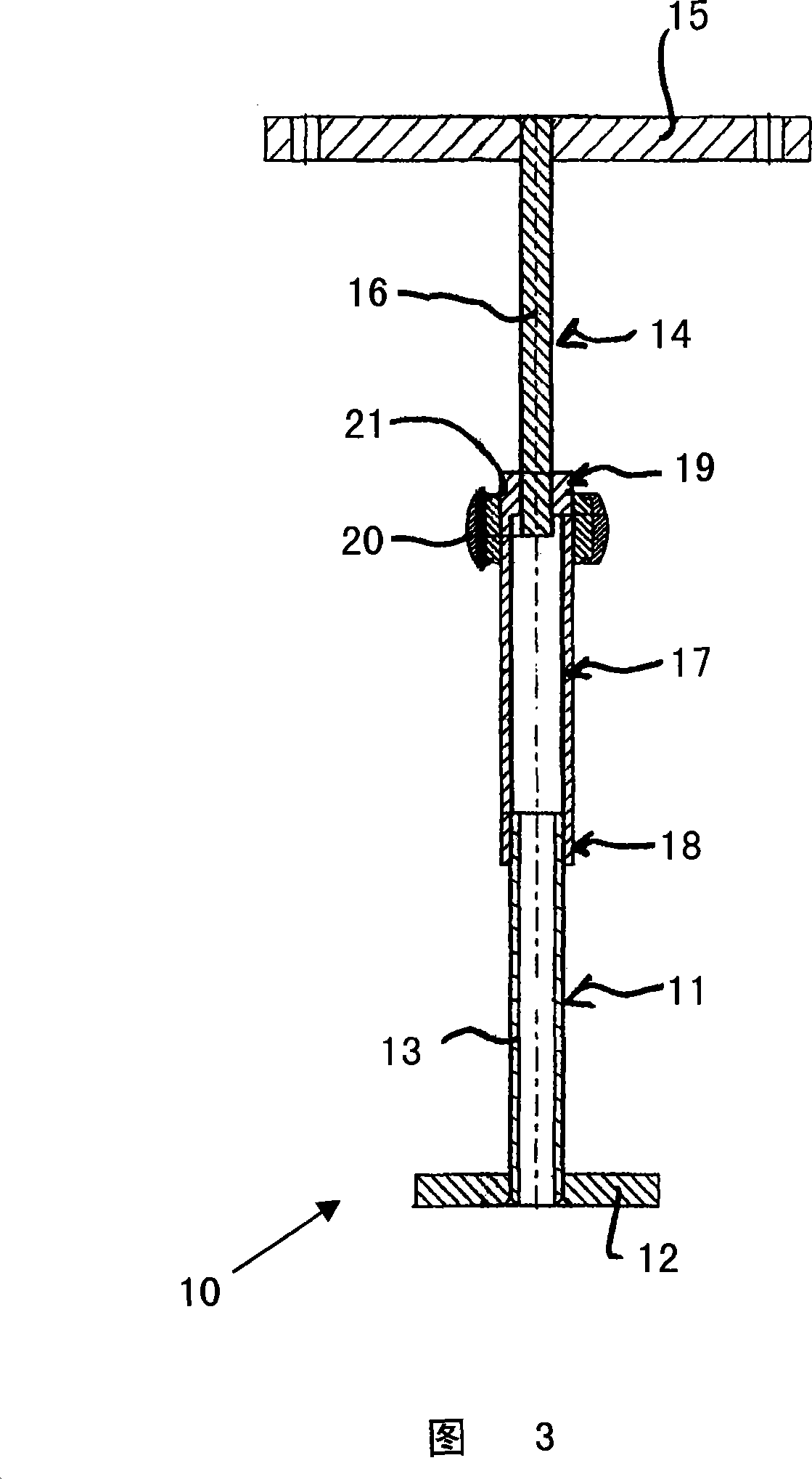

[0024] Figures 1 to 3 each show a cross-section of a lifting device 10 according to the invention in different positions, wherein in Figure 1 the lifting device 10 according to the invention has been completely moved together, and in Figure 3 it has been completely moved together. move away. FIG. 2 shows a position of the lifting device 10 according to the invention, namely a position between the fully moved-in position in FIG. 1 and the fully extended position in FIG. 3 .

[0025] According to FIGS. 1 to 3, the lifting device 10 according to the present invention has two base bodies, namely a first base body 11 and a second base body 14, wherein the first base body 11 has a first platform 12 and a Projecting section 13 , second base body 14 has a second platform 15 and a section 16 projecting relative to second platform 15 .

[0026] The segments 13 and 16 of the two base bodies 11 and 14 are respectively screwed and welded at the first ends to the corresponding platforms 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com