Magnetic sensor and magnetic disk apparatus

A technology of a magnetic sensor and a storage device, applied in the field of magnetic sensors, can solve problems such as the deterioration of shielding effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

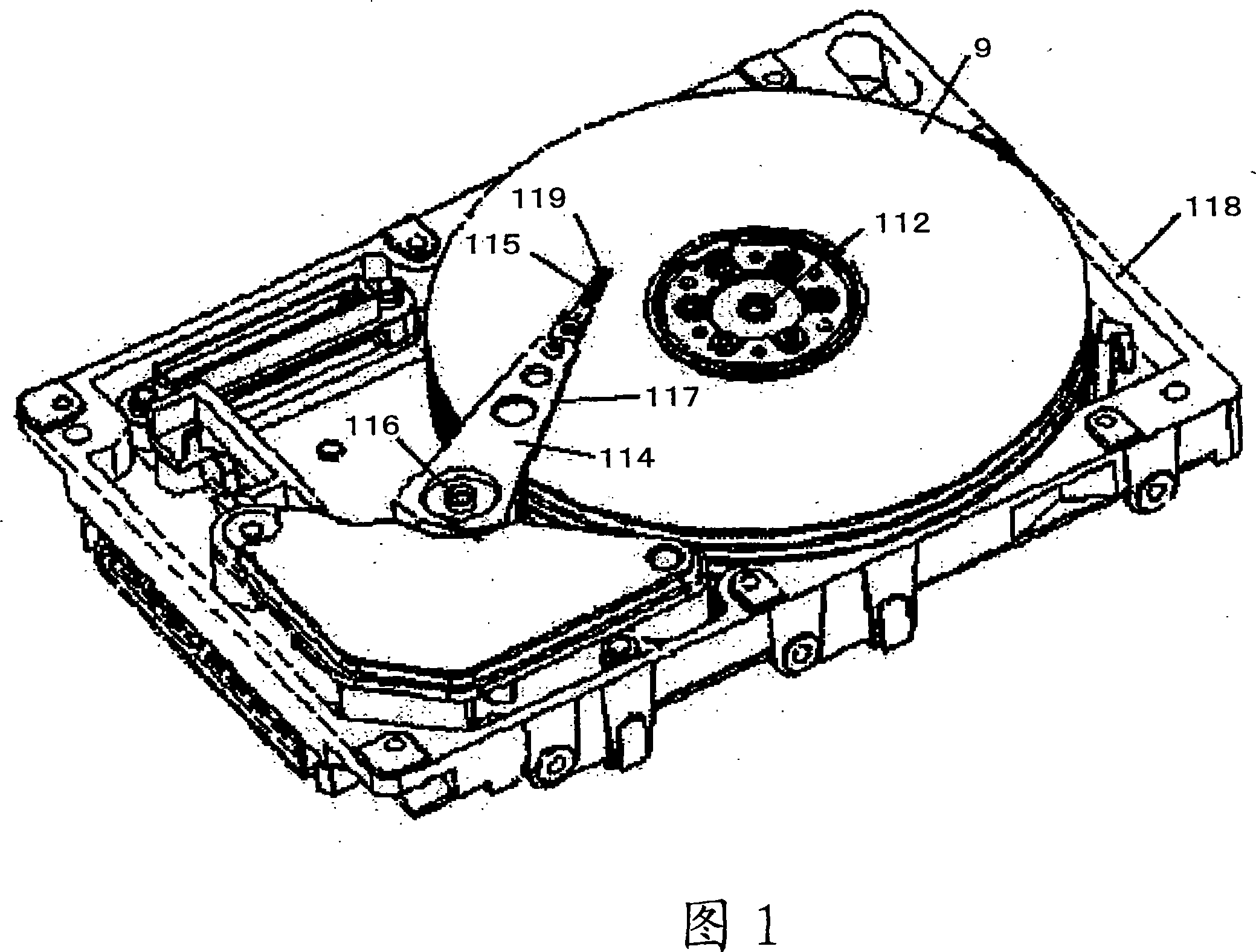

[0022] FIG. 1 is a perspective view of a magnetic disk device. The magnetic disk 9 includes magnetic information and is rapidly rotated by the spindle motor 112 . The transmission arm 114 is provided with a suspension 115 made of stainless steel. In addition, the transmission arm 116 is rotatably fixed to the housing 118 via the shaft 116 , and the transmission arm 116 moves along the radial direction of the magnetic disk 9 . Accordingly, the slider 119 mounted to the suspension 115 moves over the magnetic disk 9, thereby performing recording and reproduction of information on the track. In the housing 118, a detection circuit device for detecting a reproduced signal is fixed. The detection circuit device supplies a detection current to a magnetoresistance effect element in the reading section of the magnetic head, and measures a voltage change of the magnetoresistance effect element to reproduce information from the magnetic disk 9 .

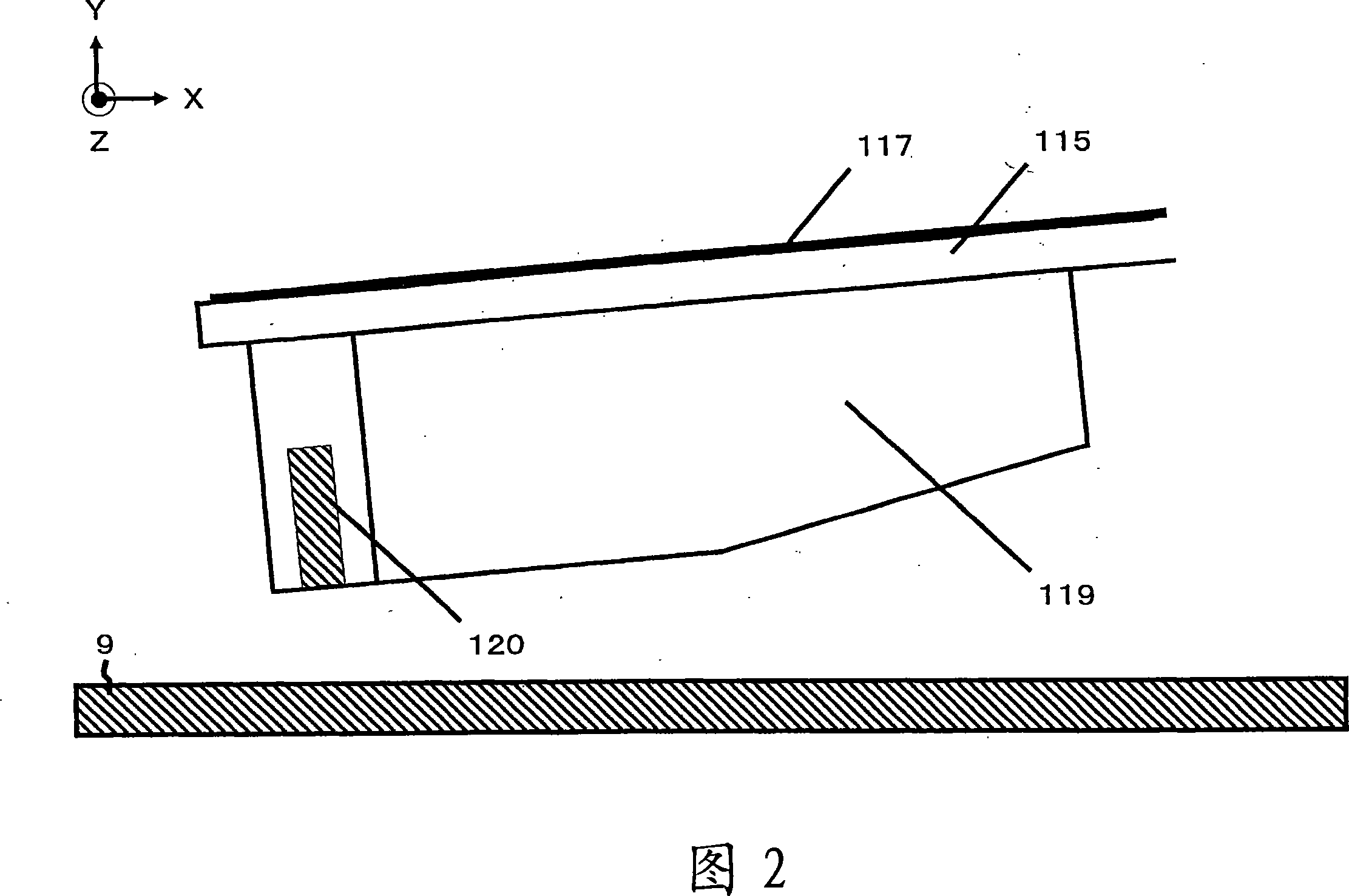

[0023] FIG. 2 is a schematic diagram ...

Embodiment 2

[0034] In Embodiment 1, a structure is described in which the lower shield electrode layer 6 and the upper shield electrode layer 4 are formed to sandwich the magnetoresistance effect element 5 in the thickness direction; however, other structures may also be formed.

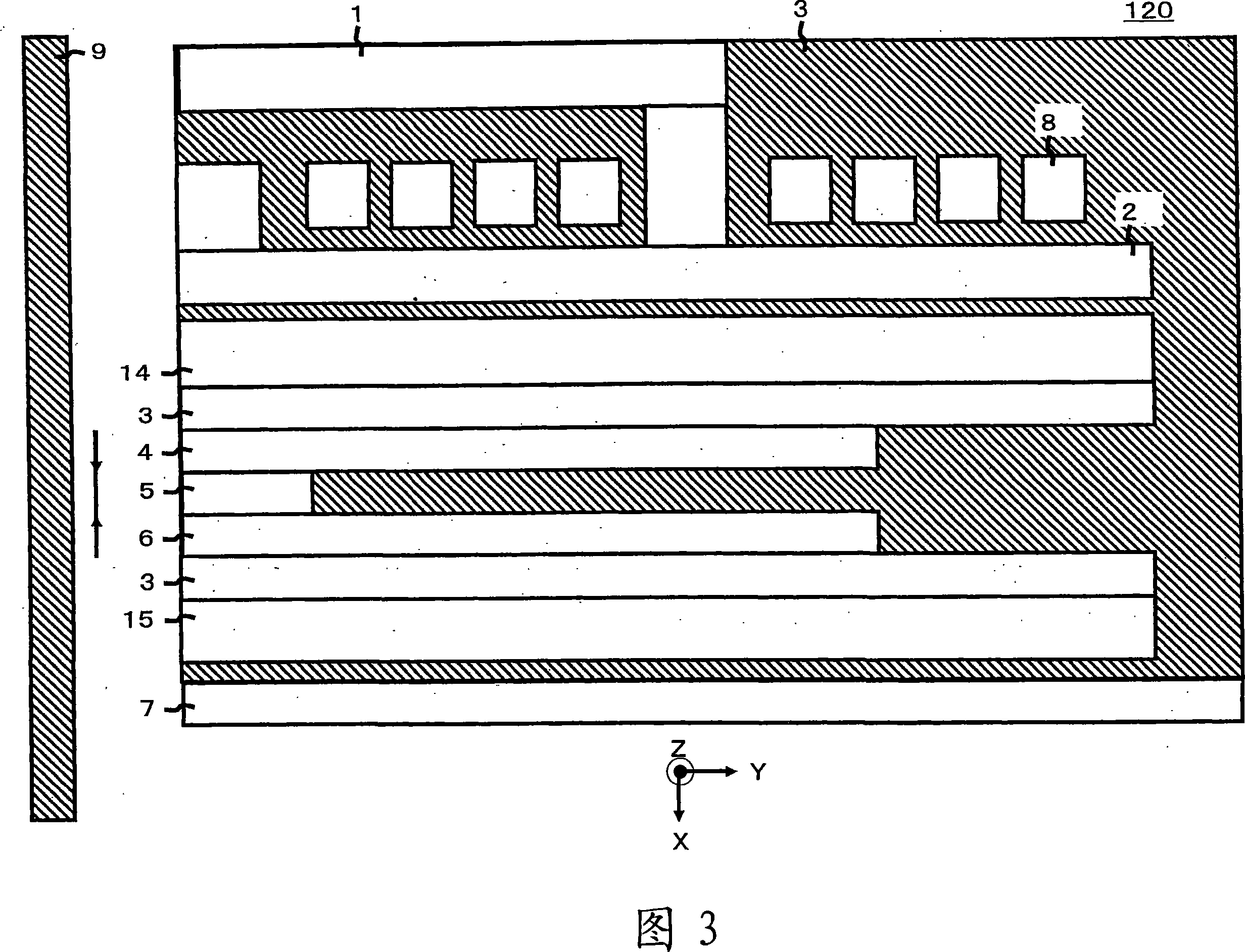

[0035] 7 is a cross-sectional view of the magnetic head 120 of Embodiment 2 taken in a direction perpendicular to the air bearing surface of the magnetic head 120 . In this magnetic head 120, the lower shield electrode layer 6 and the upper shield electrode layer 4 are formed of AlTiC (Al 2 o 3 - TiC) on the substrate 7, so that the magnetoresistance effect element 5 is sandwiched in the lamination direction. In addition, an upper shield layer 14 is formed outside the upper shield electrode layer 4 . The lower magnetic pole 2 of the write head is formed on the upper shield layer 14 , and the write coil 8 and the upper magnetic pole 1 are also formed, thereby forming the magnetic head 120 .

[0036] The lower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com