Weighing system

一种区域、基础的技术,应用在称量系统领域,能够解决耗费时间等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

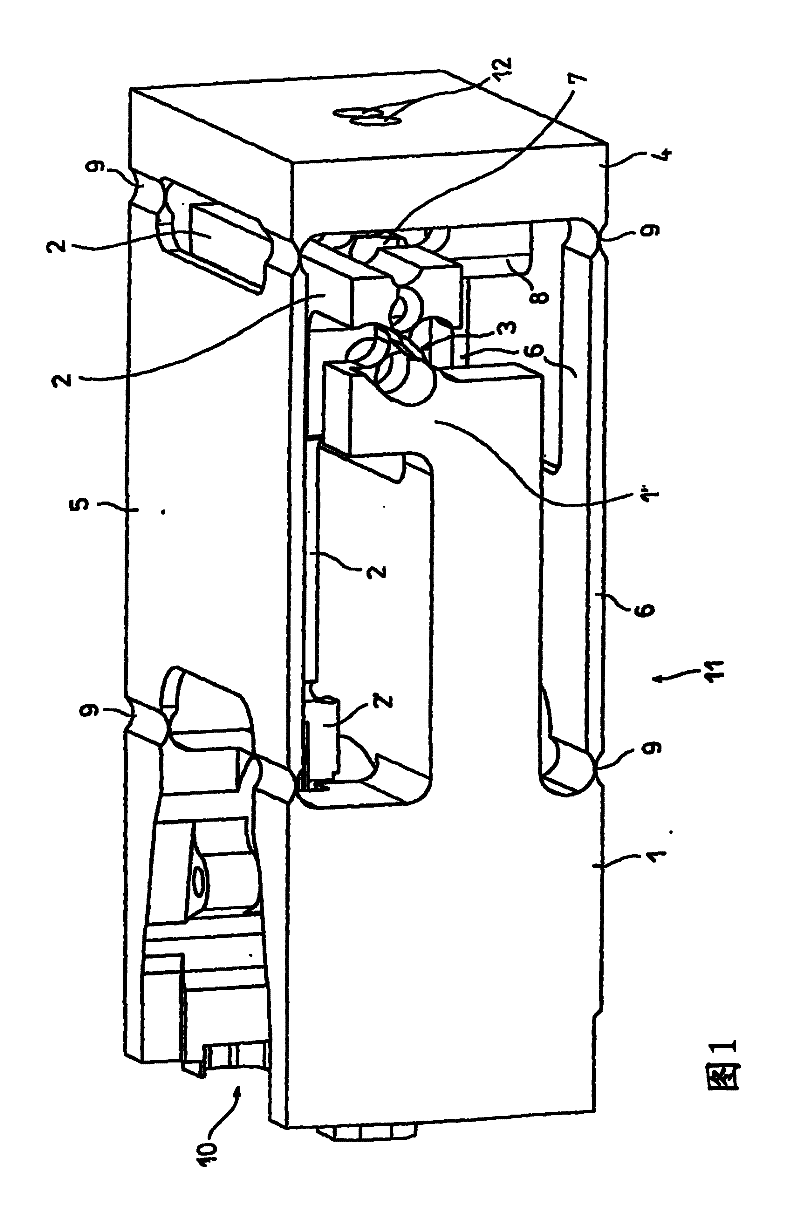

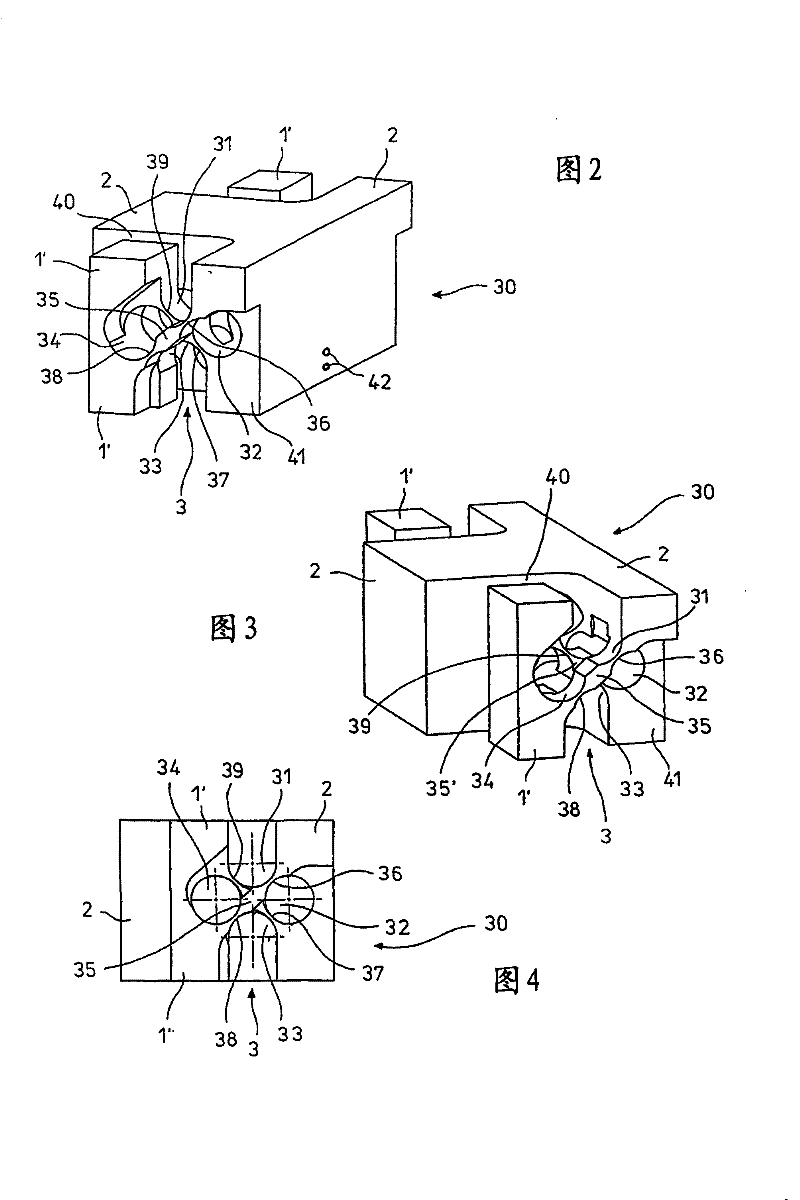

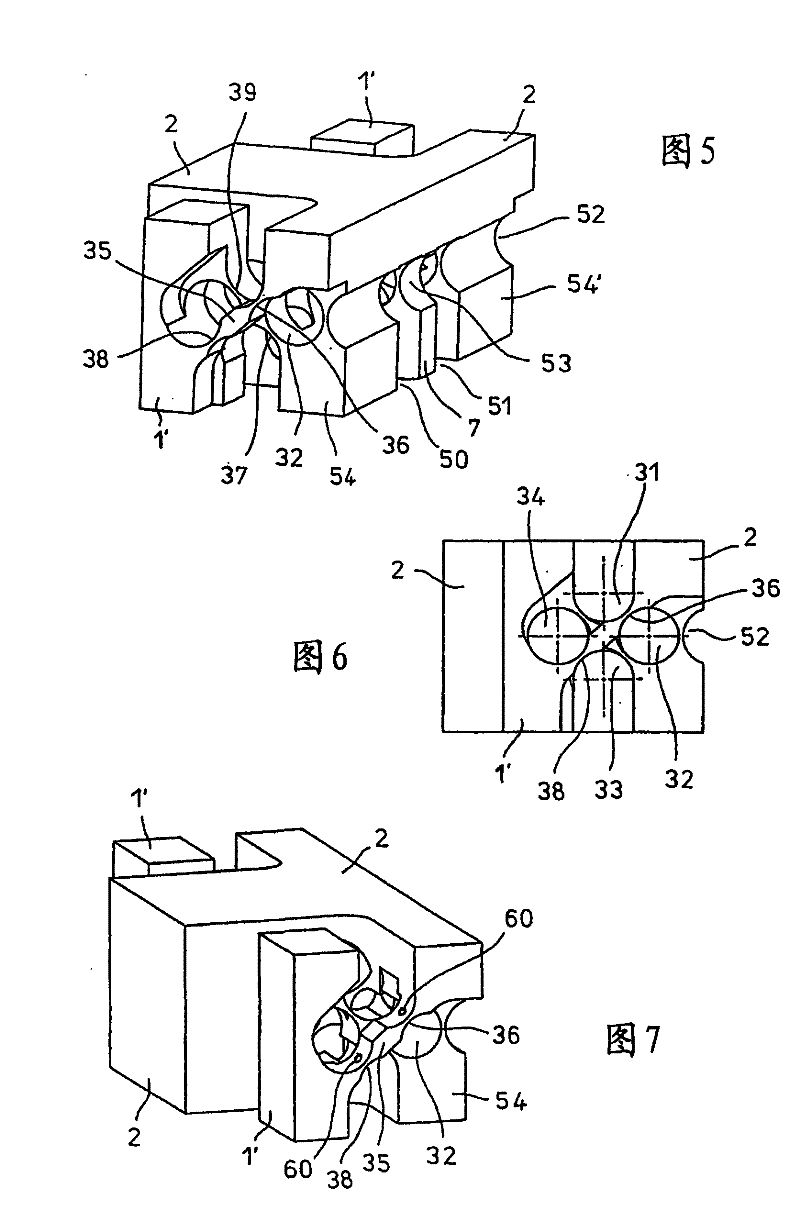

[0029] figure 1 The weighing system 11 shown in a perspective view in the figure includes a base area 1 fixed to the housing and a bearing seat 4, which is movable in the vertical direction in the form of parallel guide rails through an upper guide rod 5 and a lower guide rod 6 ground connection to the base area. Thin points of material that act as hinge points are marked with 9. The weight of the weighing item acting on the carrier 4, which for example is introduced at the hole 12, passes through a protrusion 8 and a figure 1 The coupling element 7 , which can only be partially seen in the figure, transmits to the short lever arm of a transmission lever 2 . The transmission lever 2 is pivotably mounted on a raised part 1 ′ of the base area 1 via a cross spring joint 3 . On the long lever arm 2' of transmission lever 2, it is fixed on figure 1 Invisible coils. The coil protrudes into the air gap of a permanent magnet system, not shown, which can be fastened to the base re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com