Arrestor and method of measuring leakage current of arrestor

A lightning arrester and lightning protection technology, which is applied in the field of lightning arresters, can solve the problems of increasing the size of the insulating cap 310, and achieve the effects of size reduction, easy leakage current, and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

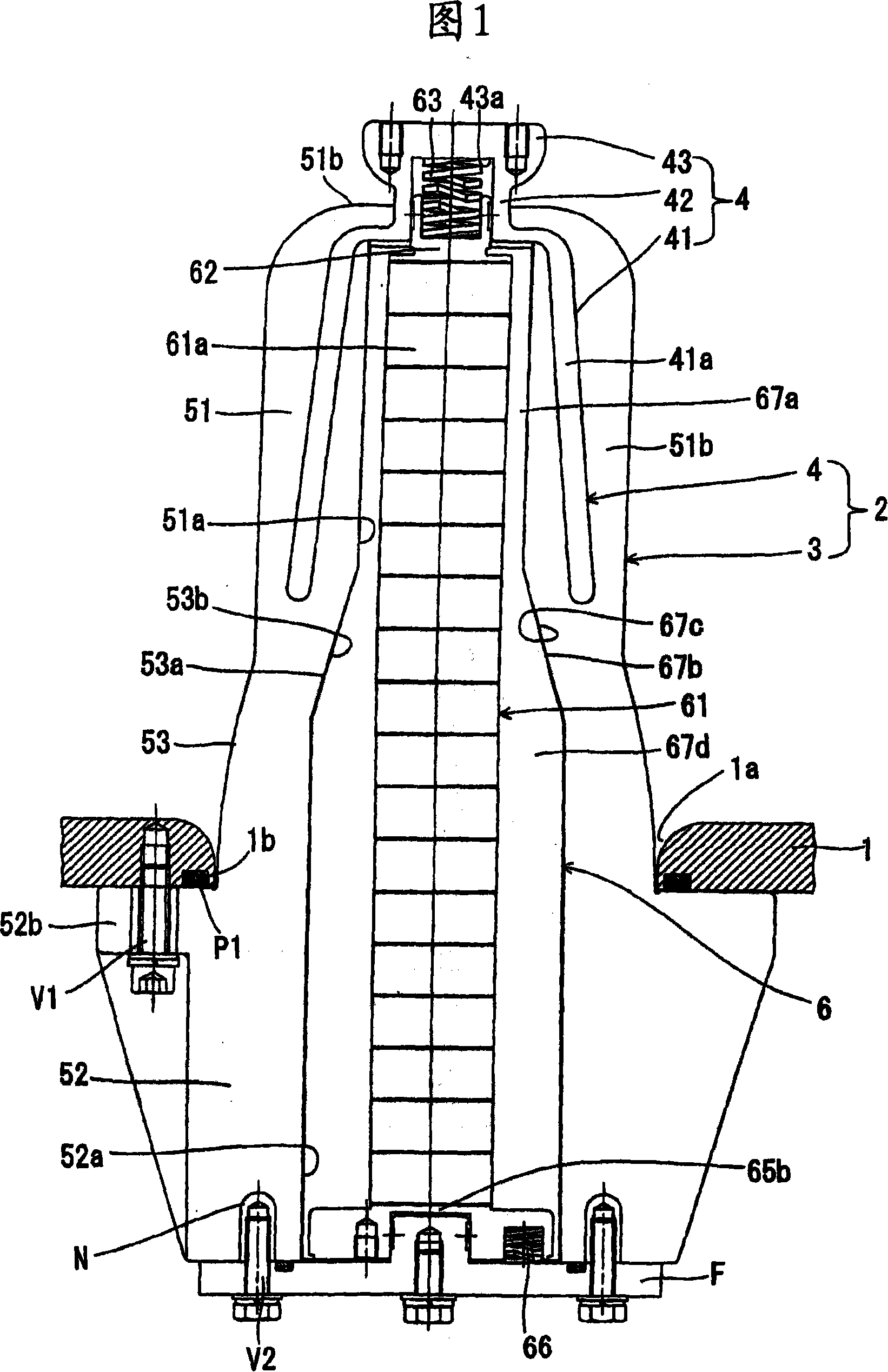

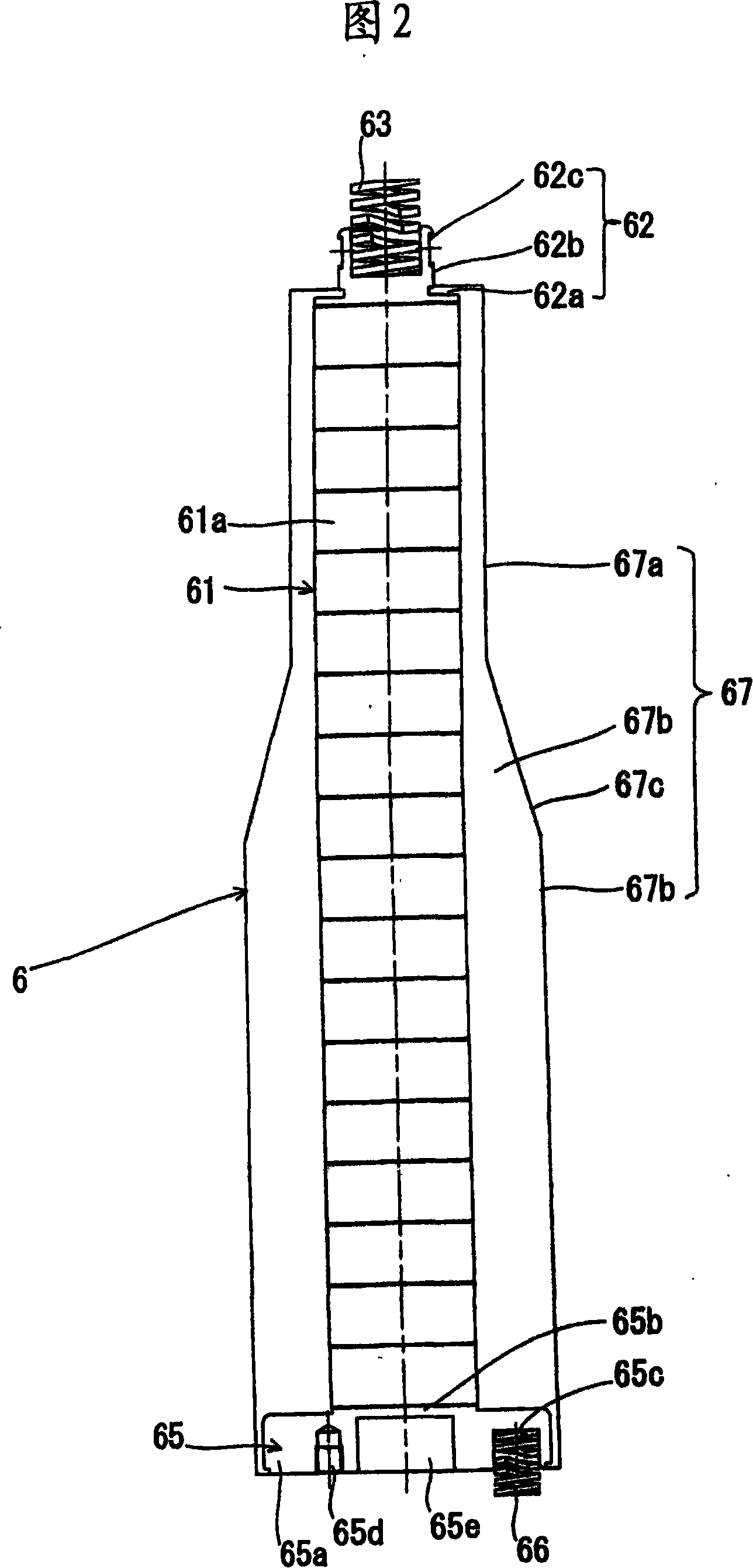

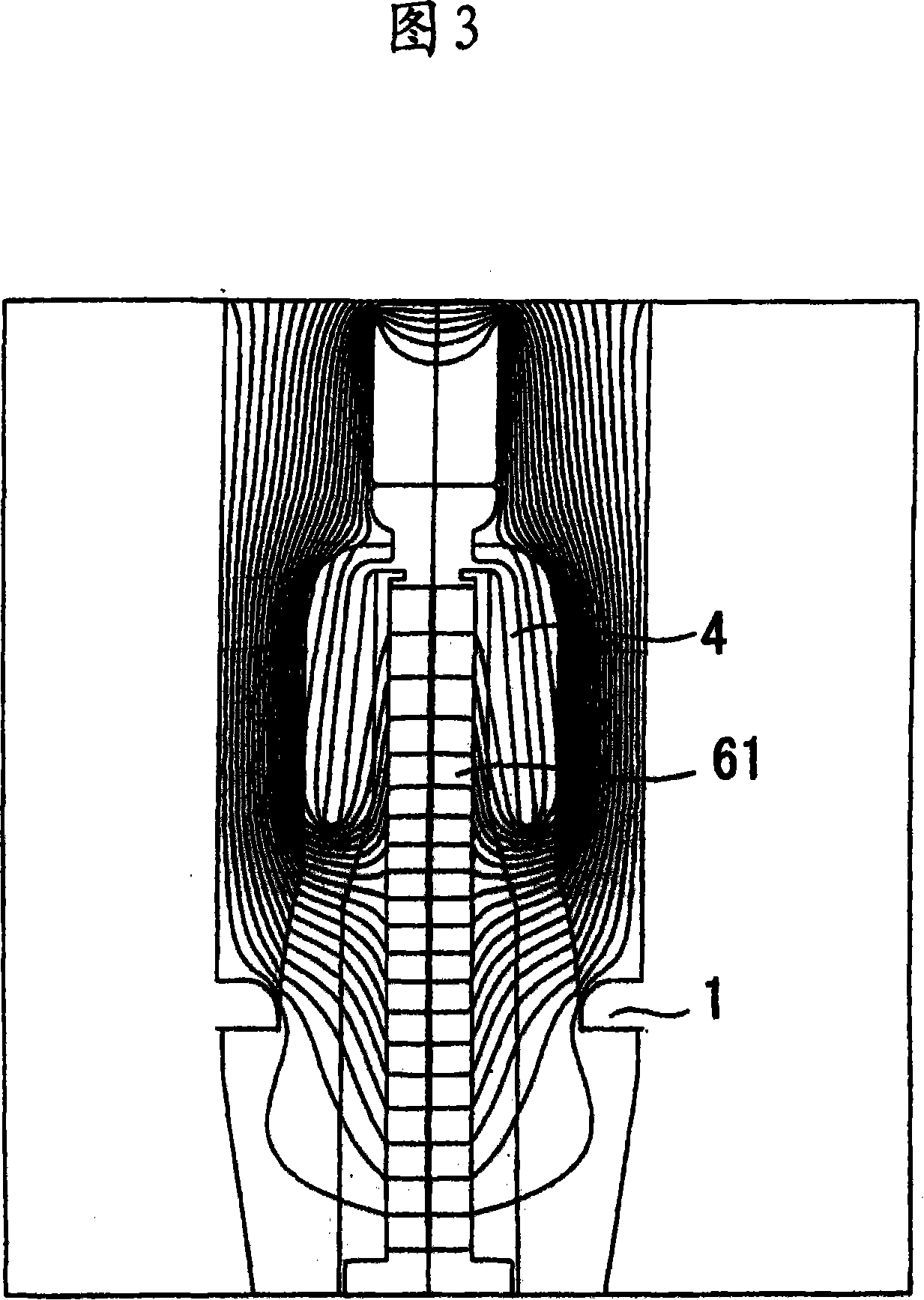

[0087] The partial sectional view in Fig. 1 shows an example of the arrester of the present invention, which belongs to the 66 / 77 kV class.

[0088] In this drawing, the electrical equipment with the lightning arrester of the present invention includes an equipment housing 1, which hermetically accommodates electrical equipment such as switches (not shown in the figure). And, an insulating gas such as SF6 or the like is charged into the device case 1 . In addition, an opening portion 1a is provided at the bottom of the device case 1, and the sleeve 2 is installed into the opening portion 1a so that the top end of the sleeve 2 itself is located inside the device case 1, and the sleeve 2 itself The rear end hermetically covers the opening portion 1a. A formed lightning protection element stack 6 is detachably installed in the sleeve 2 , wherein the formed lightning protection element stack 6 has a lightning protection element stack 61 which will be mentioned below.

[0089] The ...

no. 2 approach

[0108] Fig. 4 is a partial sectional view of a lightning arrester according to a second embodiment of the present invention. Meanwhile, in the drawings, the same reference numerals are used to designate those parts that are the same as the corresponding parts in FIG. 1, and detailed descriptions are omitted.

[0109] In this embodiment, by making the sleeve 2 from an insulating material such as epoxy resin, a current cut-off area Z can be formed at the rear end of the sleeve 2 leading to the outside of the device housing 1 . Specifically, the current cut-off area Z is located at a portion extending from the end face of the rear end of the lower cylindrical portion 52 as an insulating cylindrical member toward the outer wall of the device case 1 .

[0110] For the lightning arrester of this structure, on the outside of the equipment housing 1, the grounding conductor E is installed in the current cut-off area Z located at the rear end of the sleeve 2—that is, by stacking the li...

no. 3 approach

[0113] Fig. 5(a) is a partial sectional view of the lightning arrester according to the third embodiment of the present invention, and the top view in Fig. 5(b) shows the sealing cover in this embodiment. Meanwhile, in the drawings, the same reference numerals are used to designate those parts that are the same as the corresponding parts in FIG. 1, and detailed descriptions are omitted.

[0114] In Fig. 5 (a), the formed lightning protection element stack 6 has: a lightning protection element stack 61 formed by stacking a plurality of lightning protection elements, wherein the lightning protection element uses zinc oxide as a main component; a joint conductor 62, which is installed to the lightning protection element stack 61 on the top end side (high voltage side); a cylindrical pressure metal fitting 64, which is mounted to the rear end side (low voltage side) of the lightning protection element stack 61; and a molded insulator 67d made of a material such as silicon rubber T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com