Torsion oscillation damper with journal bearing

A sliding bearing, shock absorber technology, applied in the direction of springs/shock absorbers, bearings, couplings, etc., can solve problems such as damage, insufficient cycle, rapid wear of sliding bearings and/or large increase in friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

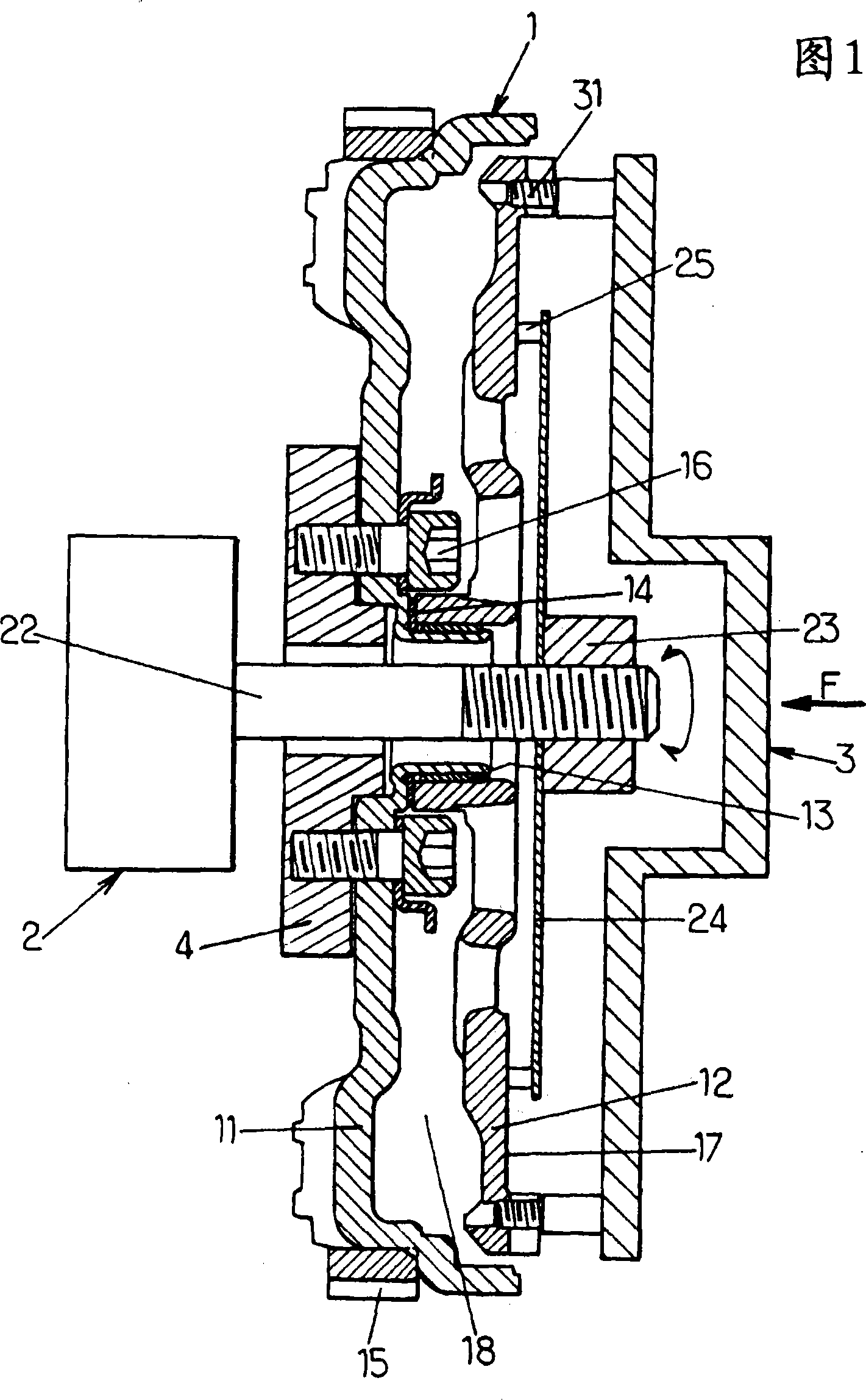

[0059] [59] As mentioned above, Figure 1 shows the device used to perform the "D20" test.

[0060] [60] FIG. 2 shows a detail shown in FIG. 1, in which the main flywheel 11, the auxiliary flywheel 12, the axial bearing 13 and the radial bearing 14 are shown.

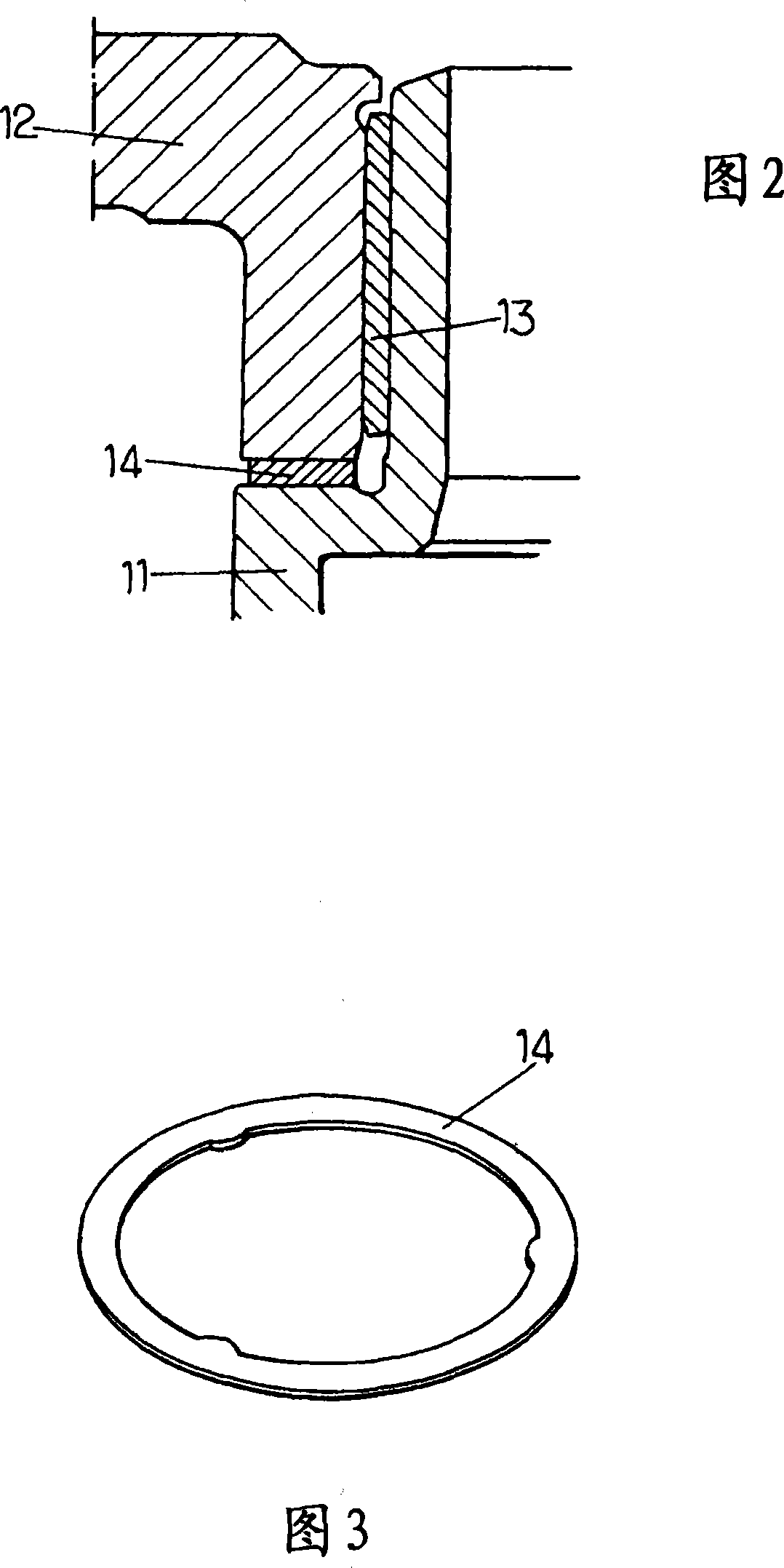

[0061] [61] FIG. 3 shows an axial bearing 13 having a substantially annular shape. According to the present invention, the axial bearing is composed of a selected polyamide-based material that contains lubricant and does not contain fiber material.

[0062] [62] In order to determine the materials that can form the bearings that make the shock absorber meet the current technical specifications, many materials have been tested under the above-mentioned "D20" test conditions.

[0063] [63] Table 1 summarizes the results of the test using axial bearings. As listed in rows 2 to 4 in the table, the constituent materials of the axial bearing are based on a matrix and contain one or more A lubricant, and optionally reinforcing fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com