Anti-vibration structure for motor

A motor and anti-vibration technology, applied in the direction of electromechanical devices, electrical components, liquid fuel engines, etc., can solve problems such as internal electronic component contact fatigue and aging, electronic system resonance effect and noise, shorten the service life of electronic systems, etc., to maintain Normal function and service life, the effect of avoiding resonance effect and vibration noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

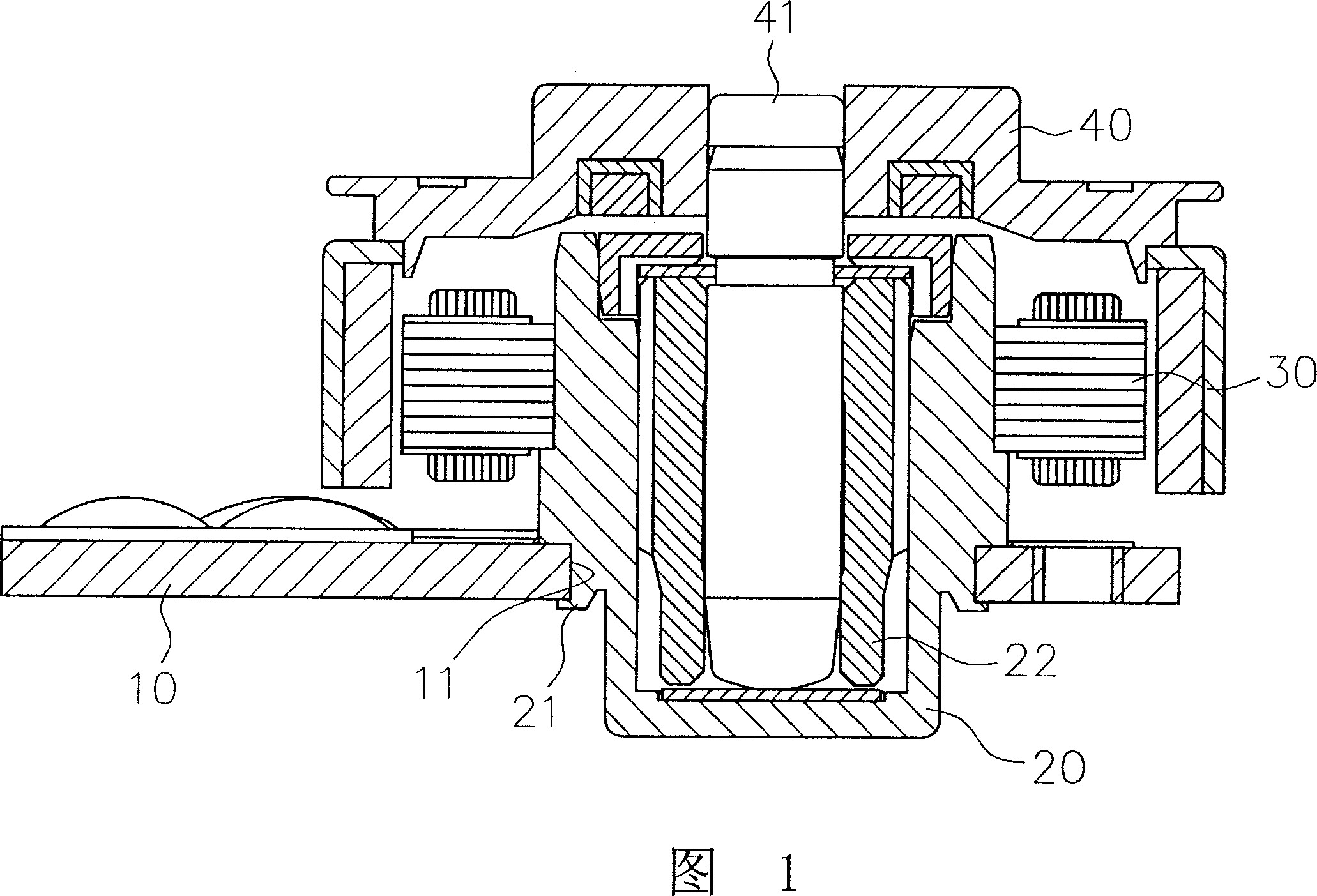

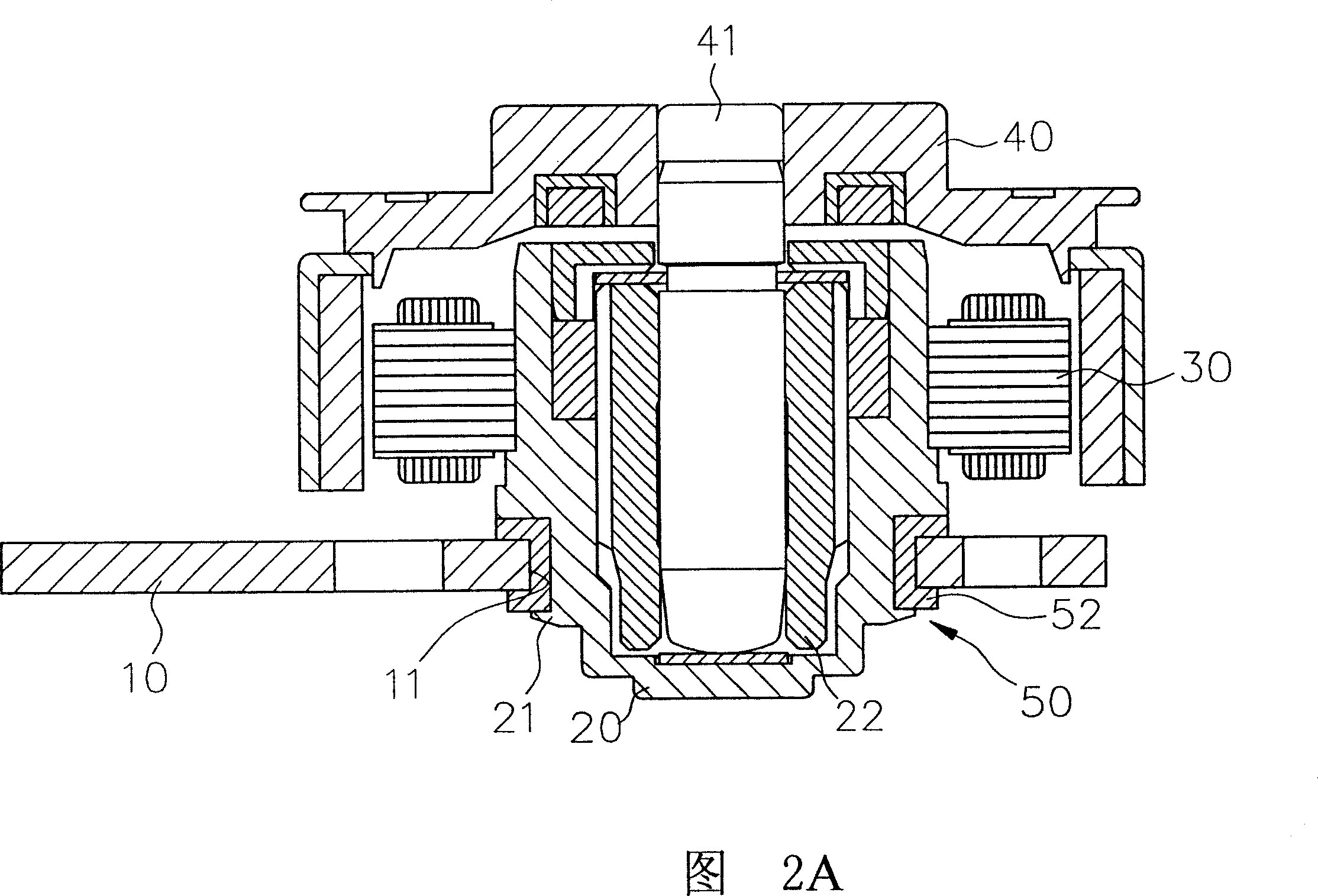

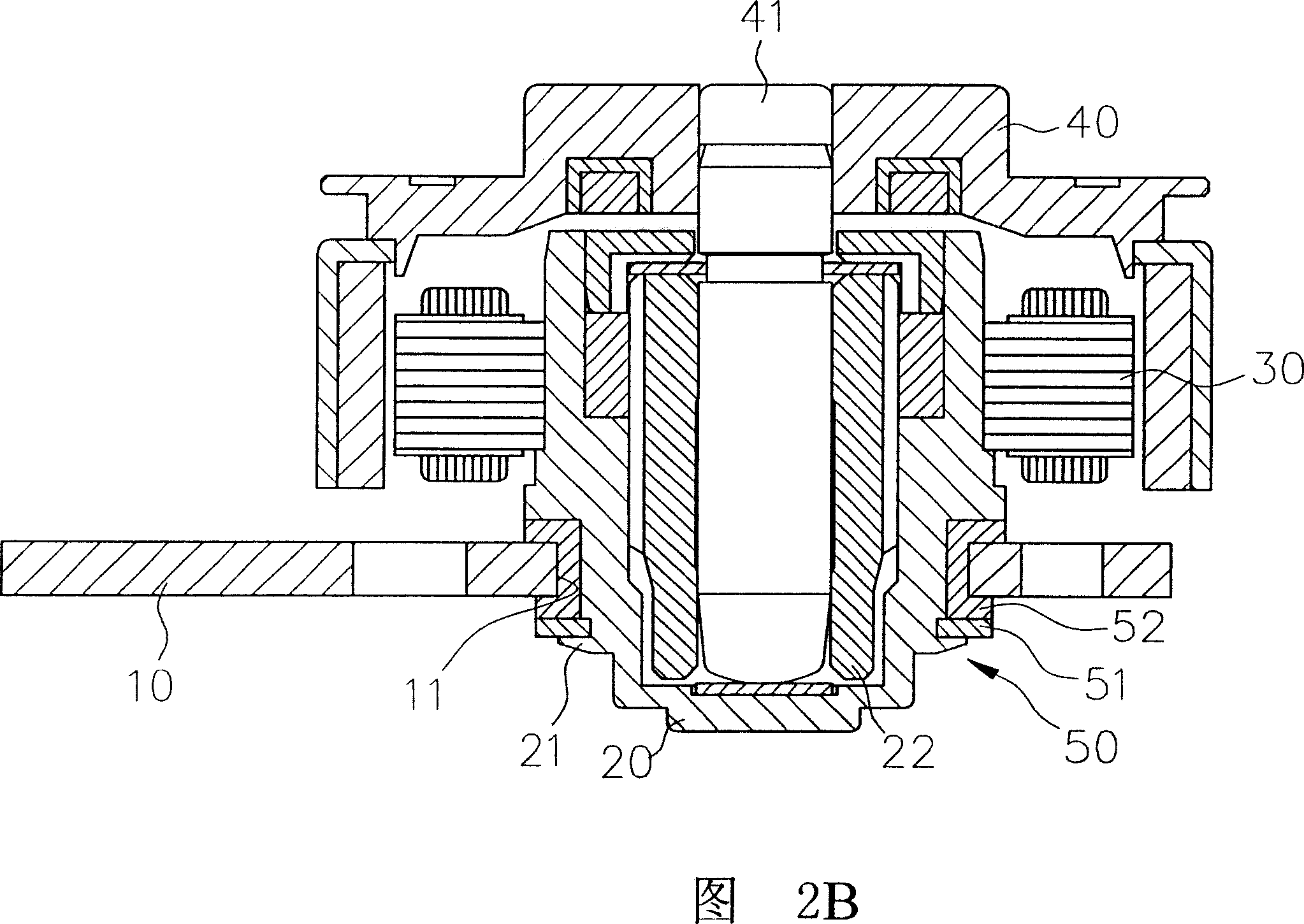

[0023] The invention relates to a vibration-proof structure of a motor. An anti-vibration component with vibration-absorbing and buffering functions is arranged between the metal tube and the bottom plate of the motor, so that the vibration generated by the rotation of the motor rotor and the vibration generated by the friction between the rotating shaft and the bearing are not large. It will be directly transmitted to the bottom plate to block the impact of vibration on the electronic system.

[0024] The following lists the embodiments of the present invention that are actually applied to the spindle motor and describes the structural features and functions of the present invention in detail with reference to the accompanying drawings.

[0025] As shown in FIG. 2A and FIG. 2B , it is the first embodiment of the present invention applied to a spindle motor. The spindle motor includes a bottom plate 10 , a metal tube 20 , a stator assembly 30 and a rotor 40 .

[0026] The bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com