Tyre unstacker

A technology of unstacking machines and tires, which is applied in the direction of unstacking, transportation and packaging of objects, which can solve the problems of cumbersome control, complicated equipment, high cost, etc., and achieve the effect of simple structure, simple operation and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

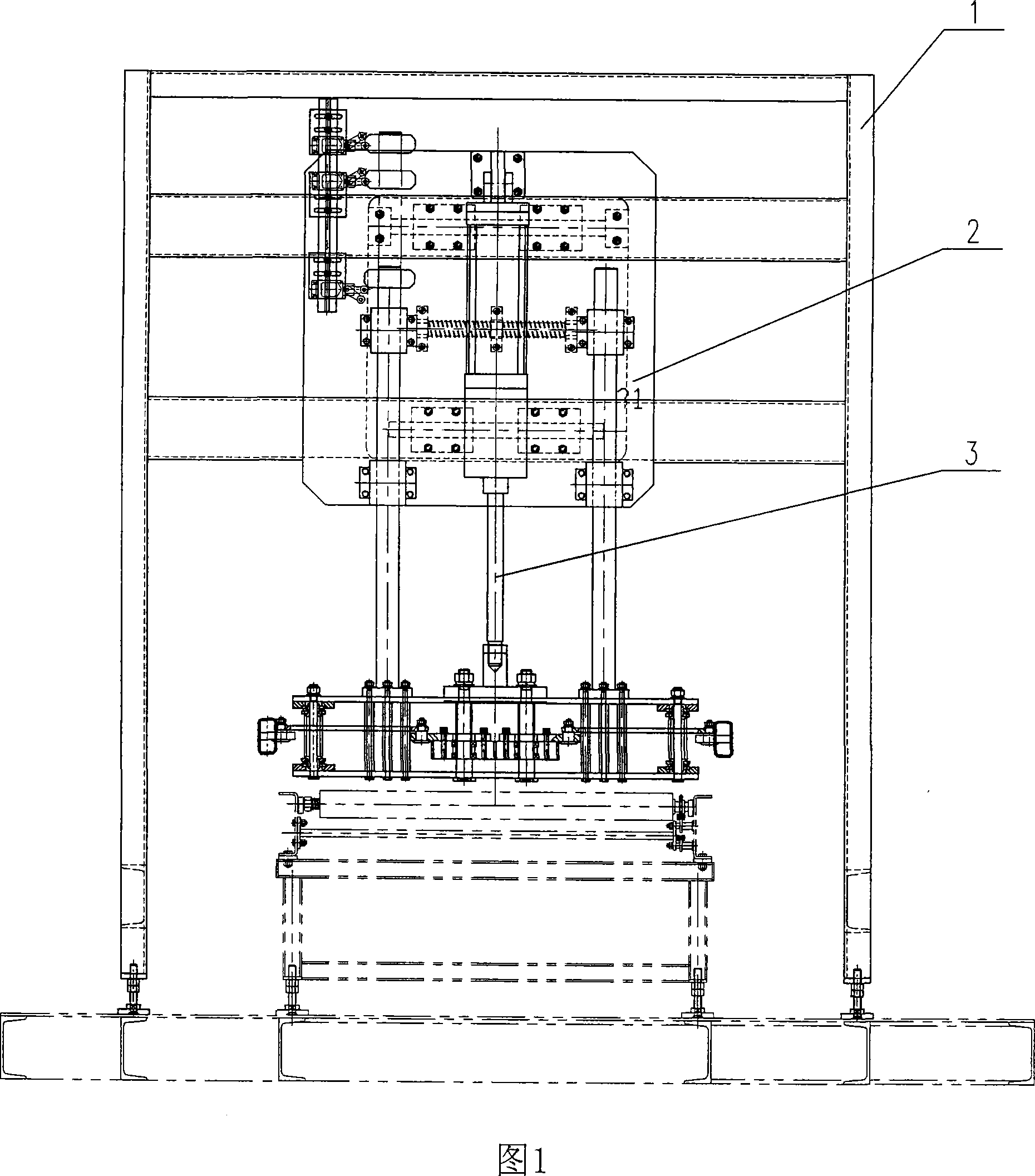

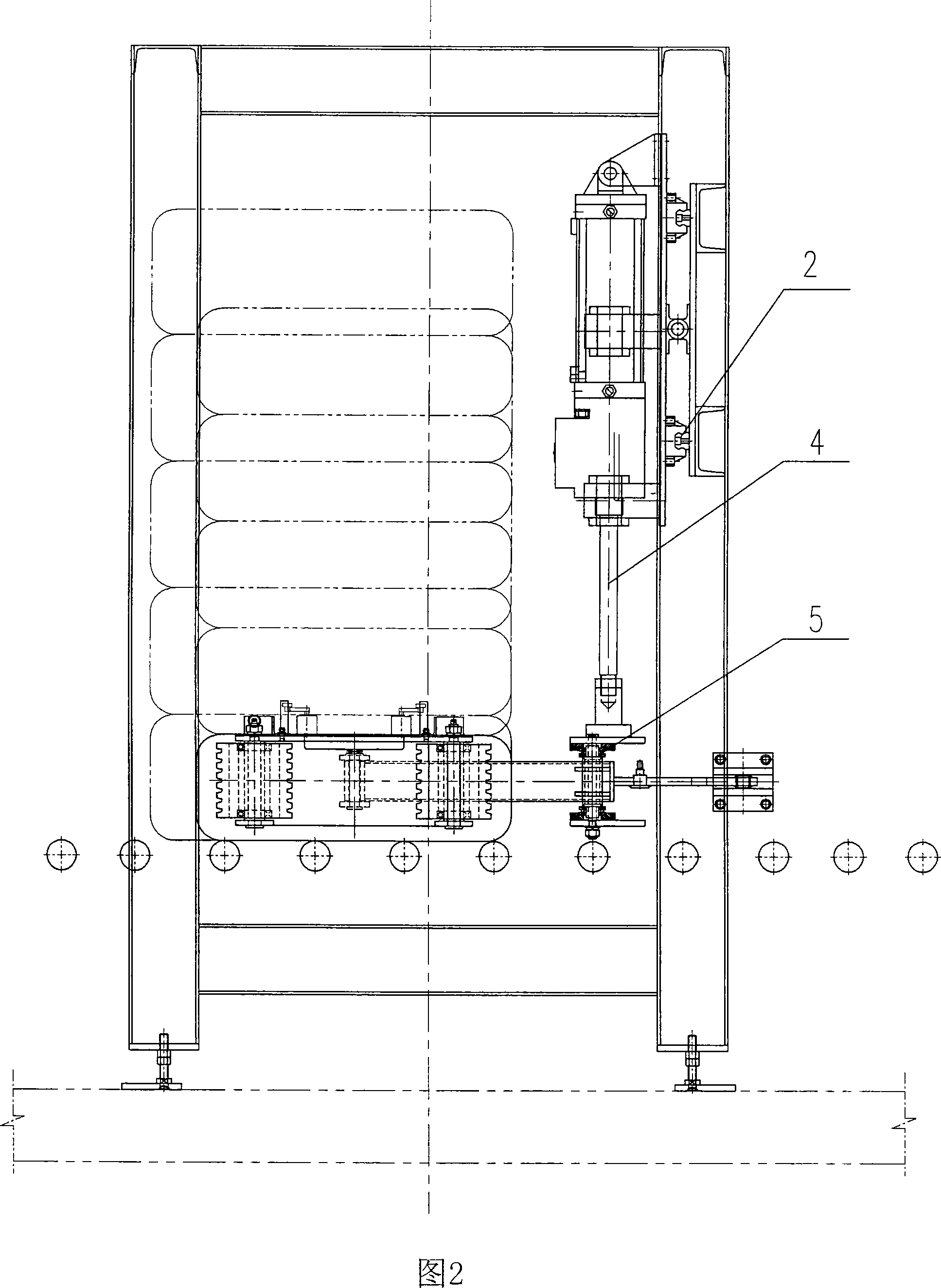

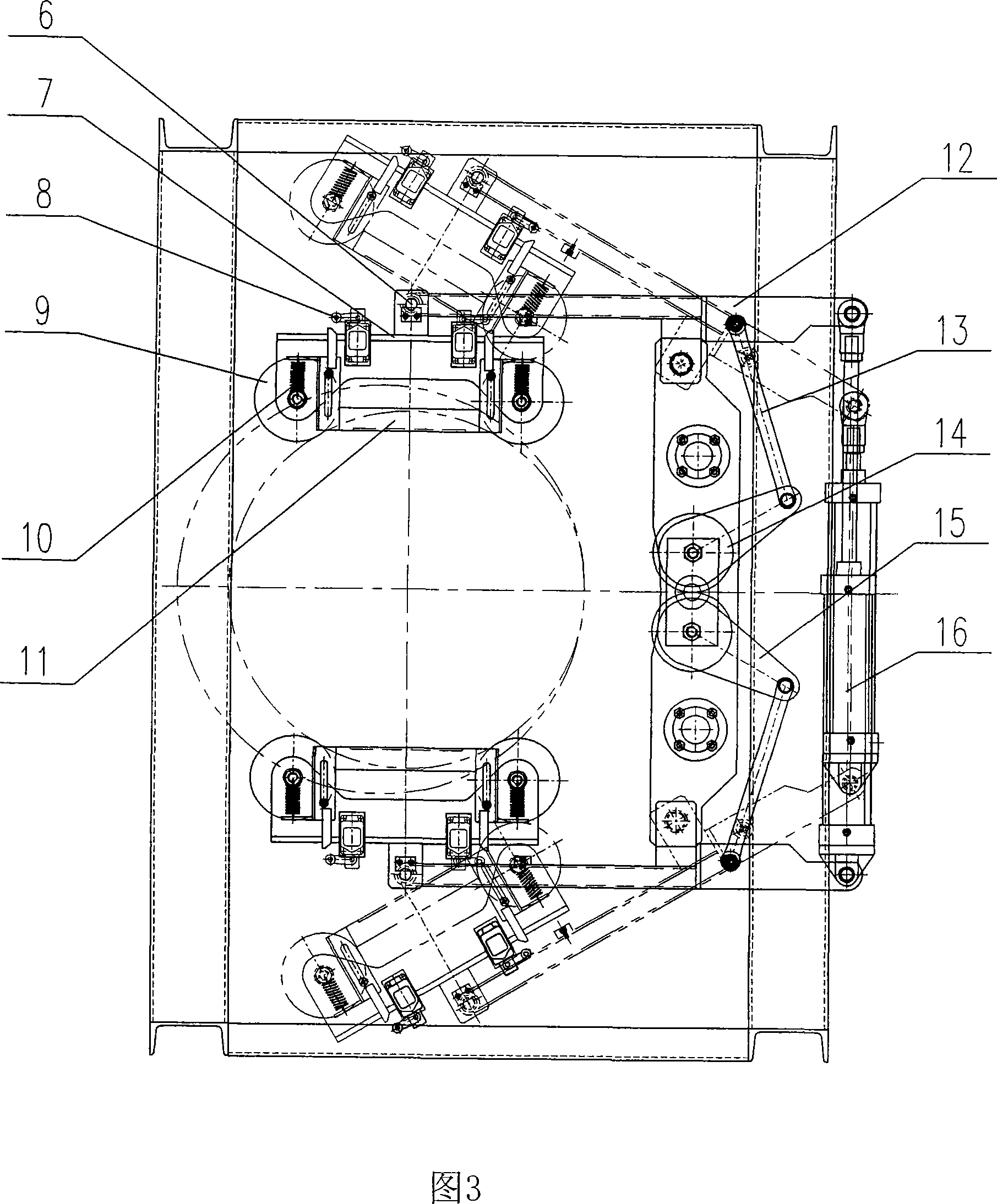

[0016] The present invention mainly consists of a bracket 1, a straightening device 2, a lifting cylinder 3, a guiding device 4, a lifting support 5, a rotating shaft 6, a clamping frame 7, a clamping confirmation switch 8, a clamping wheel 9, a return spring 10, a number Rod 11, pivoting arm 12, connecting rod 13, reverse gear 14, connecting plate 15, clamping cylinder 16, lifting switch group 17, straightening slider 18, guide rod 19, guiding support 20, straightening return spring 21 and so on.

[0017] As shown in Figure 1, Figure 2, and Figure 3: the entire lifting assembly is installed on the straightening device, which can automatically correct the deviation of the tire position after stacking. The whole set of straightening device and lifting components are installed vertically above the raceway line.

[0018] The bracket 1 is welded and fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com