Tire dismantling and stacking dual purpose machine

A dual-purpose, tire-based technology, which is applied in the stacking, unstacking, transportation and packaging of objects, can solve the problems of large space occupation, complex structure, loud noise, etc., and achieve small footprint, improved efficiency and reliability performance, noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

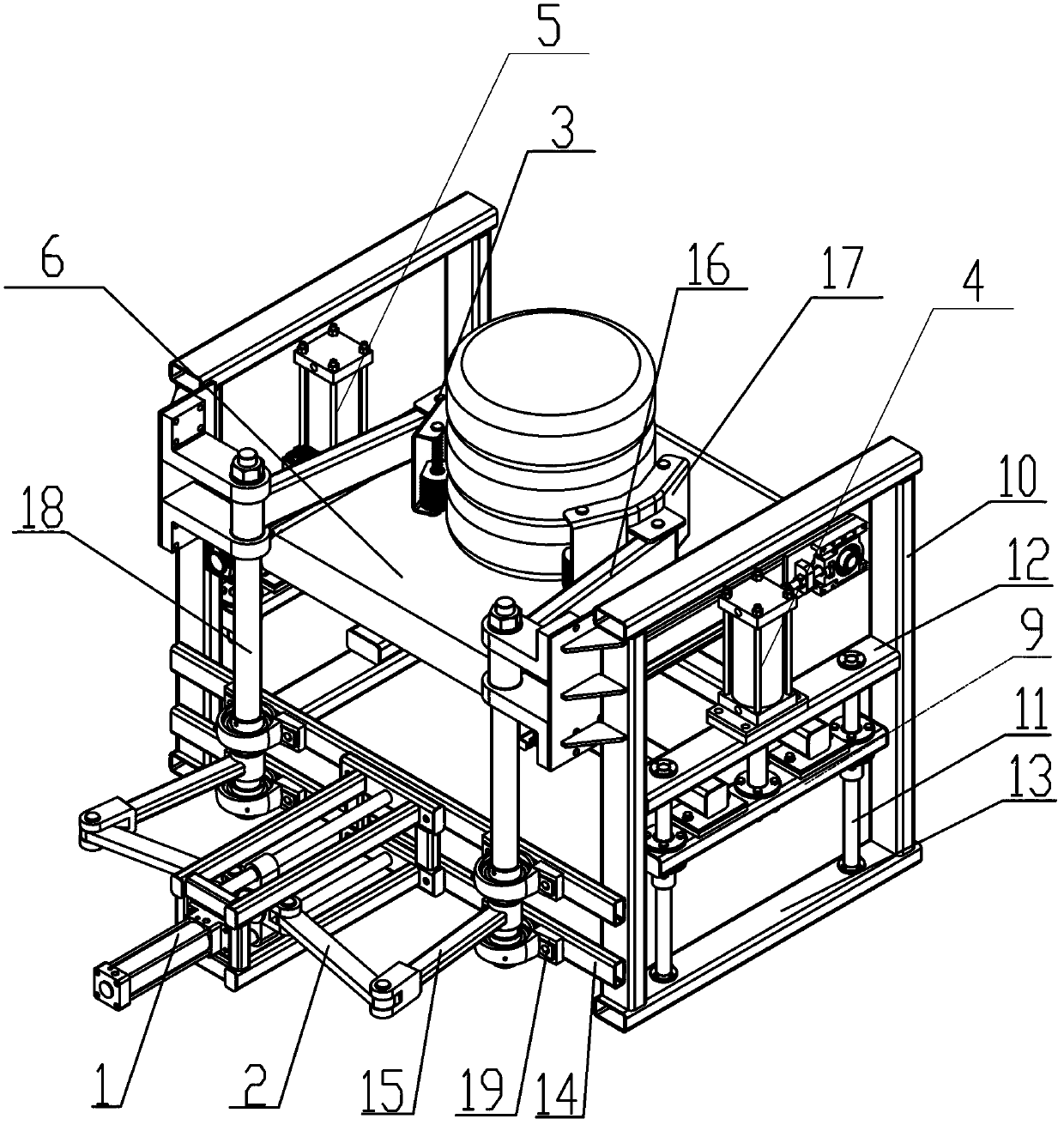

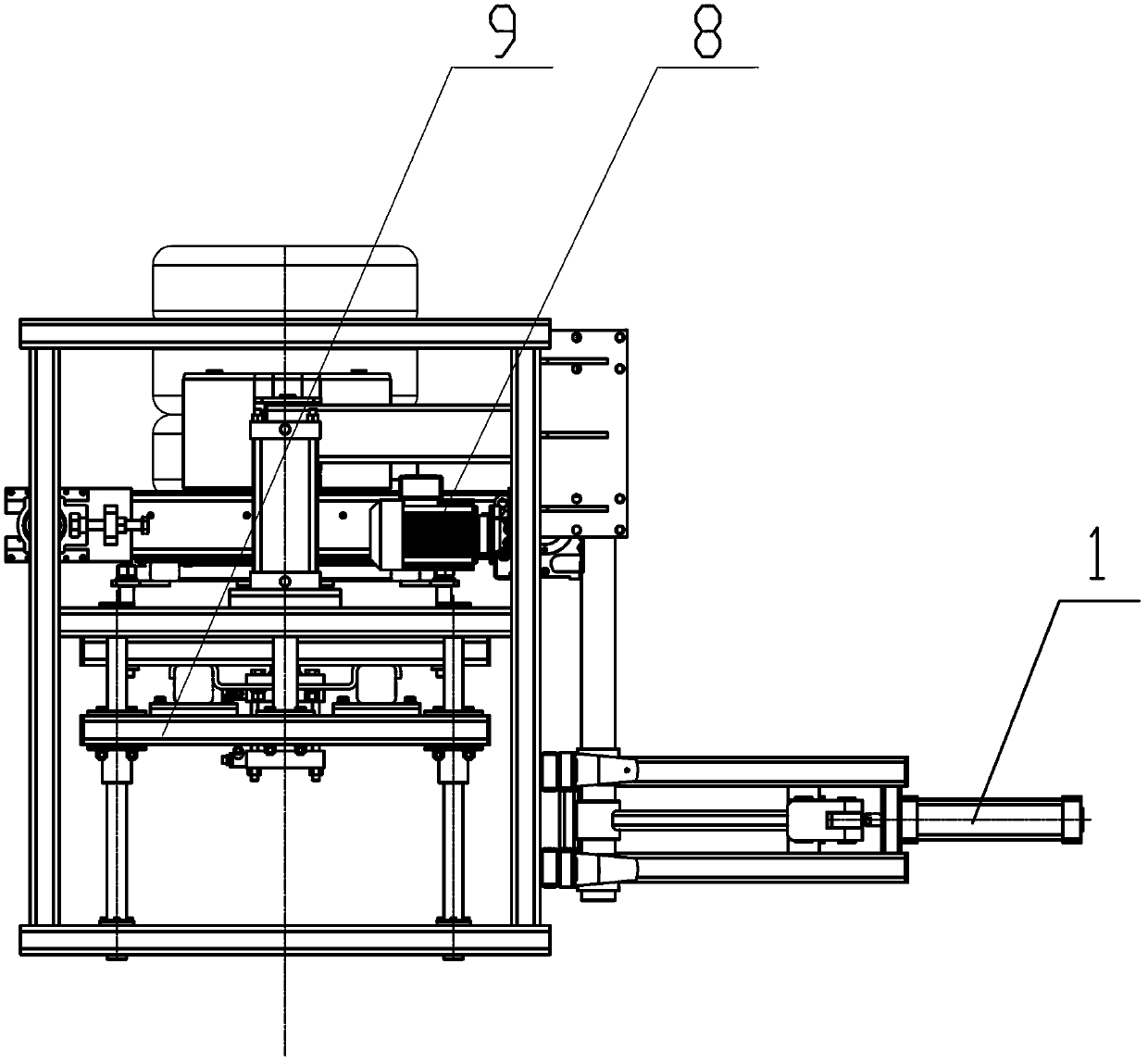

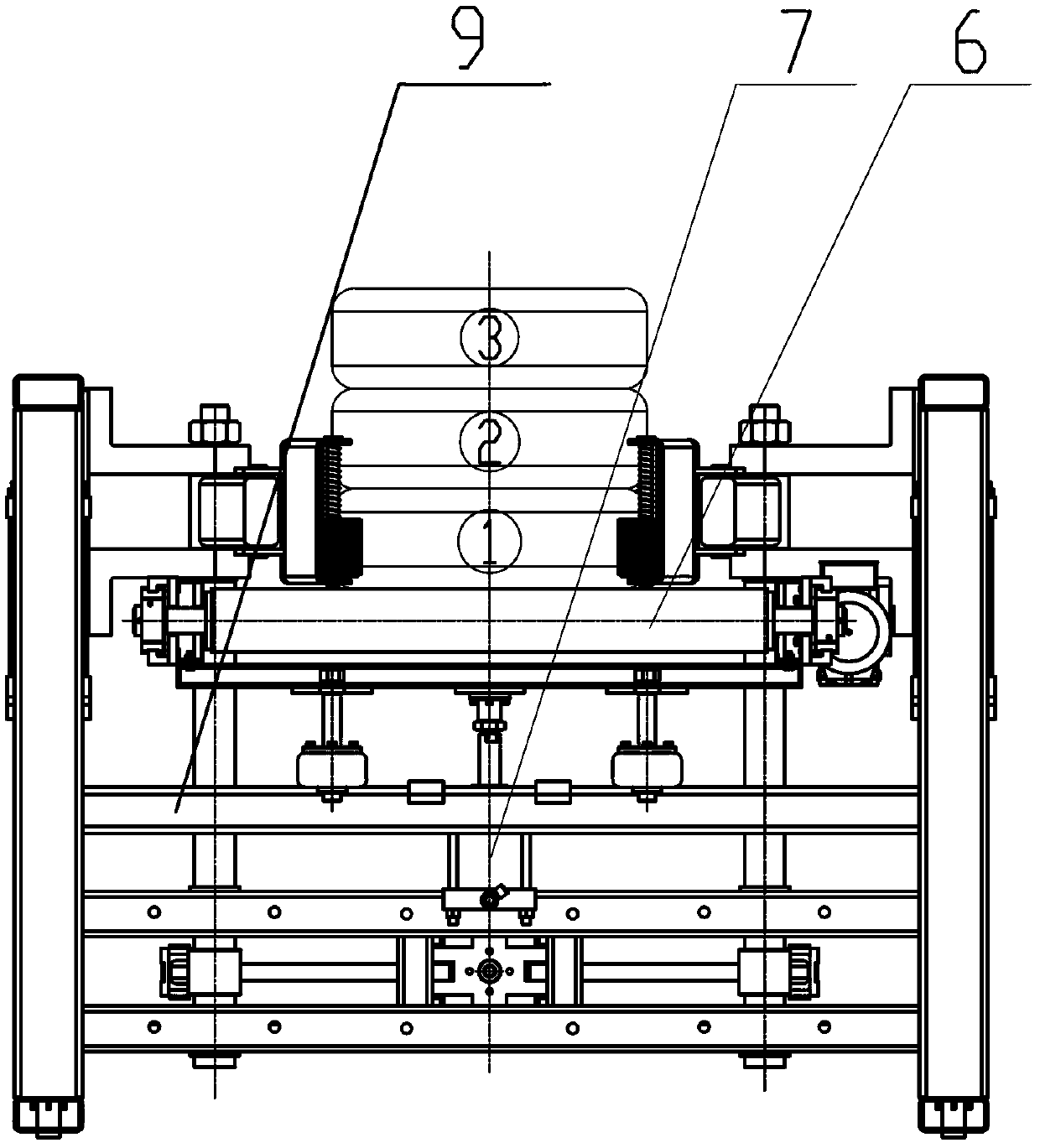

[0015] figure 1 , 2 , 3, including the first cylinder 1, connecting rod 2, manipulator 3, lifting cylinder 4 and 5, belt conveyor 6, small stroke cylinder 7, motor 8, sliding table 9, frame 10, sliding table guide rail 11, fixed Plate 12, frame bottom plate 13, slide rail 14, pivoting arm 15, clamp arm 16, holding clamp 17, transmission rod 18, slide seat 19 etc.

[0016] Such as figure 1 , 2 As shown in , 3, the dual-purpose machine for unstacking tires of the present invention, a sliding table lifting mechanism is set on the frame 10, and the sliding table lifting mechanism is connected to the belt conveyor 6 through a fixed rod, and the frame 10 is also provided with a manipulator 3, so The manipulator 3 is connected to the first cylinder 1 through a connecting rod device.

[0017] Described slide table elevating mechanism comprises ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com