Electromechanical BIM two-dimensional and three-dimensional integrated assembly type automatic universal family manufacturing method

A production method and assembly technology, applied in the direction of design optimization/simulation, geometric CAD, etc., can solve the problems of increased workload of repeated family building, complicated replacement of legends, and high requirements for operators' construction operation and maintenance experience, so as to reduce labor Add and adjust operations, improve the efficiency and quality of drawing, and avoid the effect of repeated construction of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

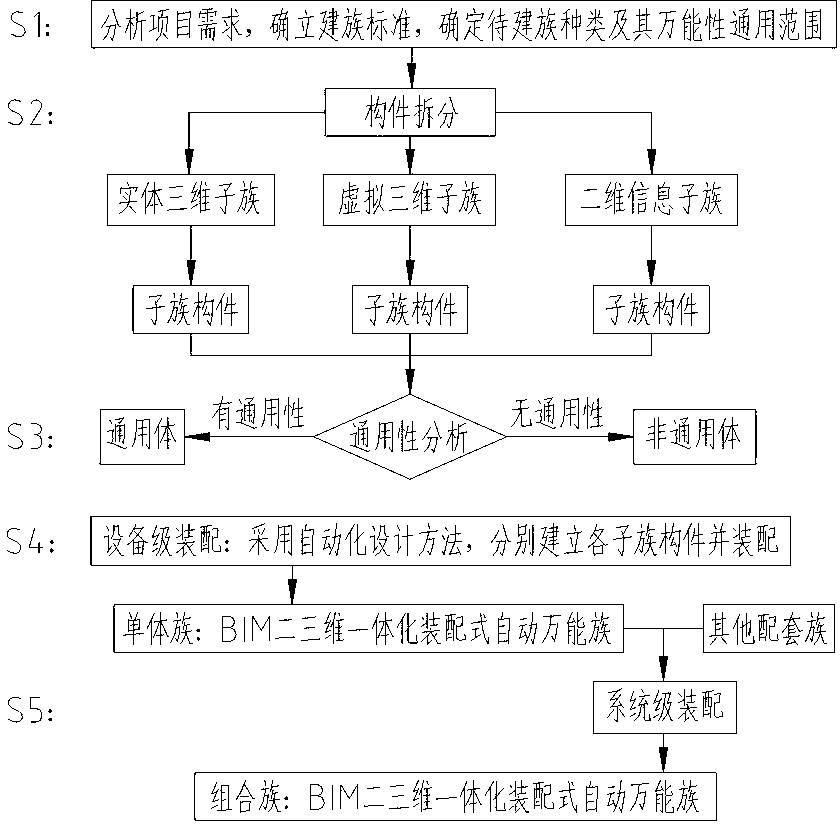

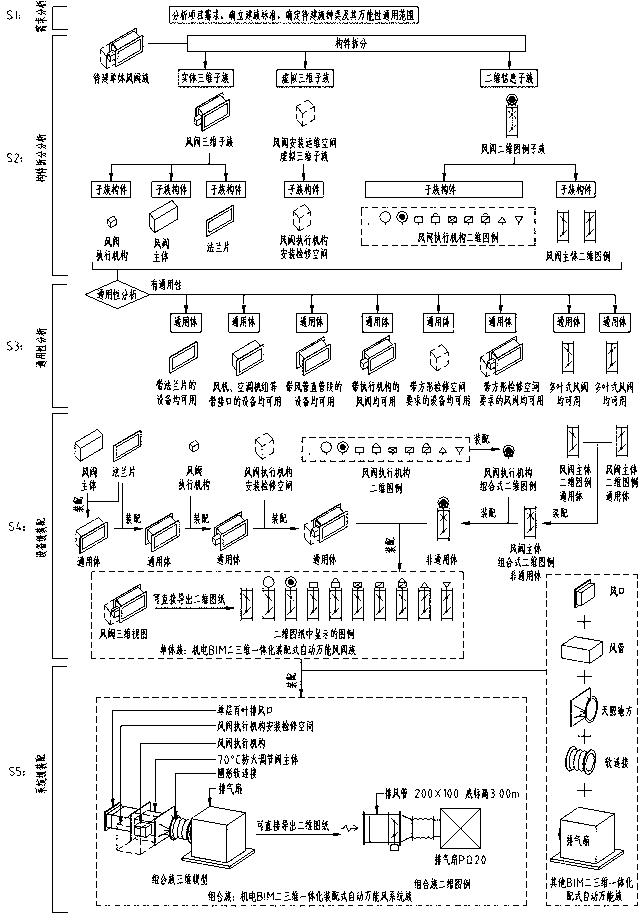

[0041] Such as Figure 2-3 As shown, the manufacturing method of the mechanical and electrical BIM 2D and 3D integrated assembly automatic universal family includes the following steps:

[0042] Step S1, analyze the project requirements, and determine the following two items:

[0043] (1) Family standards for family building: family platform and version for family building, family naming standards, three-dimensional information fineness standards for components, equipment performance parameter setting standards, equipment management information parameter setting standards, and parameter linkage standards between BIM application files etc. You need to make corresponding settings when creating a family.

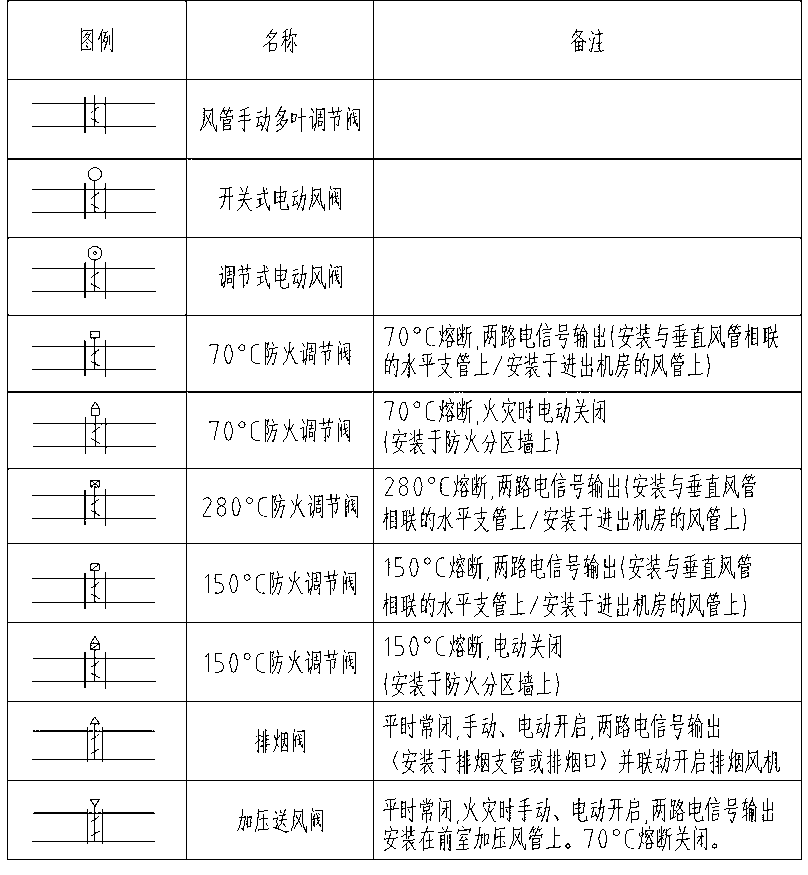

[0044] (2) Generic range of family universality: it is obtained by analyzing the legend of the project, among which, 10 square air duct valves (see figure 2 ) have a great similarity, and are very suitable to be solved by a universal family solution, which can achieve univer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com