Method for manufacturing micro-torsion shaft

A technology for twisting shafts and wafers, which is used in the manufacture of microstructure devices, microstructure technology, microstructure devices, etc., to achieve good structure, improve reliability and withstand stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

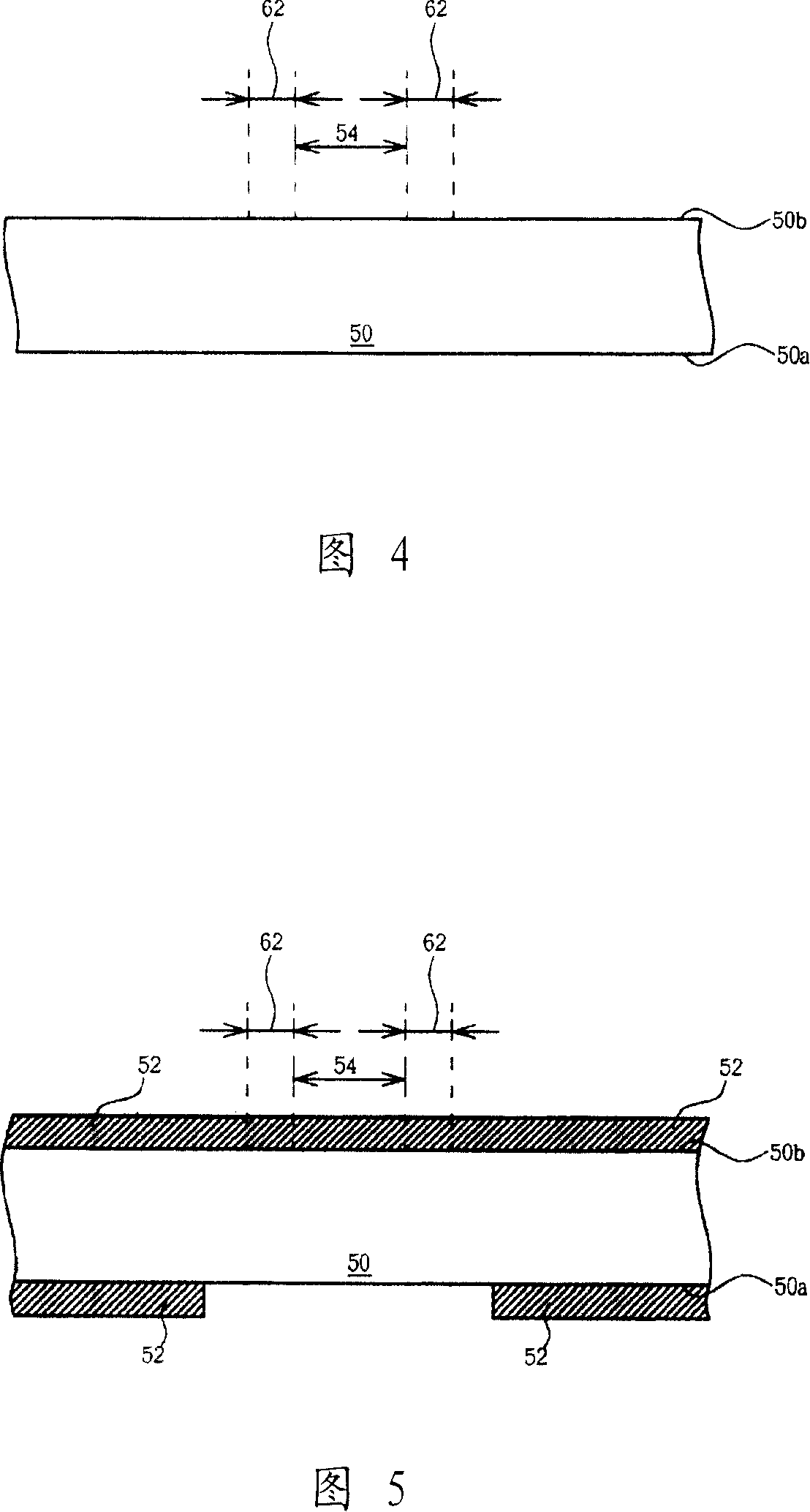

[0026] Please refer to FIGS. 4 to 12 . FIGS. 4 to 12 are schematic diagrams of a method for fabricating a micro-torsion shaft according to a preferred embodiment of the present invention. As shown in FIG. 4, a wafer 50, such as a silicon wafer, is first provided. The wafer 50 includes a first surface 50a and a second surface 50b. The second surface 50b is usually the front side of the wafer 50 and has many devices and components. The first surface 50a It is the backside of the wafer 50 . The wafer 50 defines at least one torsion axis region 54 and at least two penetration regions 62 .

[0027] As shown in FIG. 5 , an etching mask 52 is formed on the first surface 50 a and the second surface 50 b of the wafer 50 , and the etching mask 52 exposes at least the torsion axis region 54 of the first surface 50 a , and can optionally be The second penetration region 62 and the wafer 50 around the second penetration region 62 are exposed on the first surface 50a. The etching mask 52 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com